Membrane switch

A membrane switch and relationship technology, applied in the field of electrical switches, can solve the problems of corroded conductors, poor use comfort, poor contact, etc., and achieve the effects of avoiding oxidation and corrosion, good pressing comfort, and short connection distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

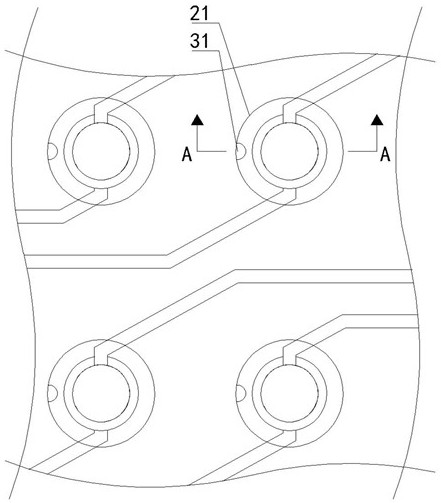

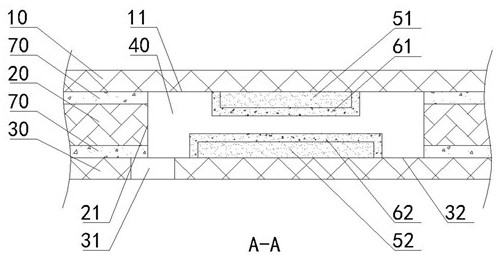

[0029] Such as Figure 1-2 As shown, the membrane switch provided by the present invention includes an upper substrate 10, a partition 20 and a lower substrate 30 arranged sequentially from top to bottom. The upper substrate 10 and the lower substrate 30 are both flexible thin film plates. The first through hole passing through the partition plate 20 in the up and down direction, the cross section of the first through hole is circular, surrounded by the hole wall 21 of the first through hole, the lower surface 11 of the upper substrate 10, and the upper surface 32 of the lower substrate 30. The formed cavity forms a pressing air chamber 40, and a conductor is arranged in the pressing air chamber 40, and the conductor includes an upper conductor 51 arranged on the lower surface 11 of the upper substrate 10 and a lower conductor 52 arranged on the upper surface 32 of the lower substrate 30, The spacer 20 is airtightly connected with the upper substrate 10 and the lower substrate...

Embodiment 2

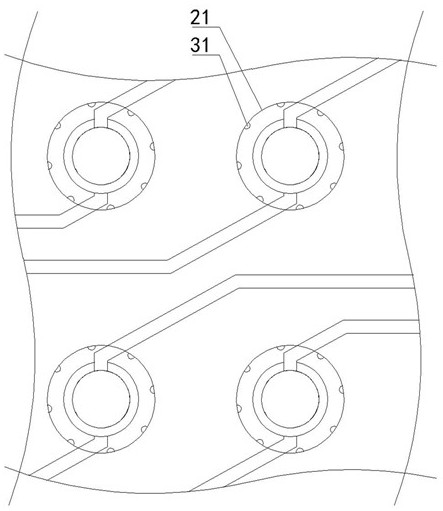

[0035] Such as image 3 As shown, the second embodiment is substantially the same as the first embodiment, the difference is that in the second embodiment, there are eight second through holes 31 communicating with a single pressing air chamber 40, and the eight second through holes 31 use the first The through-holes are distributed in a circular array with the axis line as the center. The advantage of this arrangement is that it can further reduce the impact on the strength of the lower substrate 30 under the premise of ensuring the communication area. When pressing, it can also balance the pressure in the air cavity 40. local air pressure to avoid the phenomenon that the upper substrate 10 is skewed due to the increase of local air pressure.

[0036] The membrane switch provided by the present invention adopts the idea of reducing the difficulty of water entering and leaving the pressing air cavity when water enters the pressing air cavity, and avoids the oxidation and cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com