Preparation method forming protective film by alloy surface in-situ oxidation reaction

An in-situ oxidation and protective film technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as difficult formation and self-repairing, and achieve low cost, easy operation and improved performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example A protective film of oxidation products with a three-layer structure was prepared on the surface of HP40 alloy.

[0034] After the HP40 alloy material is treated with alkali cleaning, pickling and neutralization to remove oil and rust on the surface, it is placed in a tubular heat treatment furnace, hydrogen is used as a protective atmosphere, the gas flow rate is set to 50ml / min, and K 2 SO 4 In saturated aqueous solution, the solution temperature is 20°C. The final gas is introduced into the heat treatment furnace. Heat the heat treatment furnace to 500°C at a speed of 20°C / min, keep it for 8 hours, then heat it up to 1000°C, and keep it for 4 hours. After the heat preservation is over, cool down with the furnace, and turn off the gas after reaching 150°C.

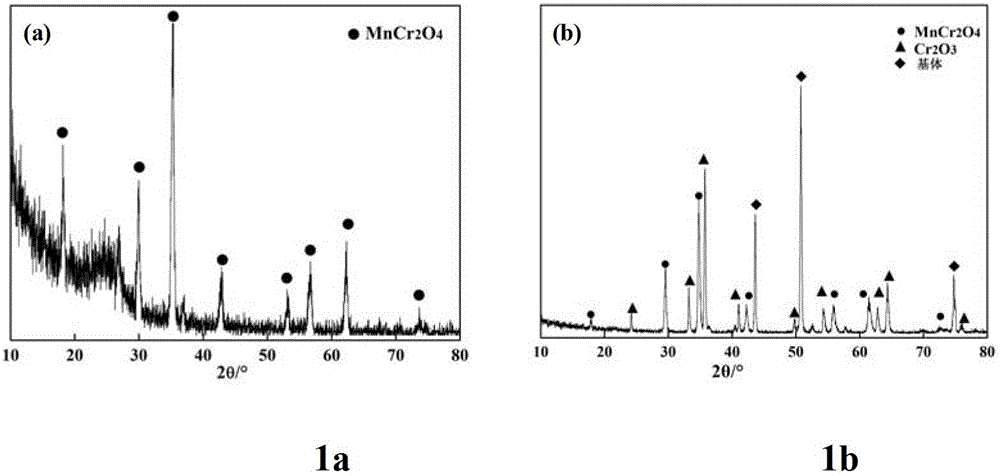

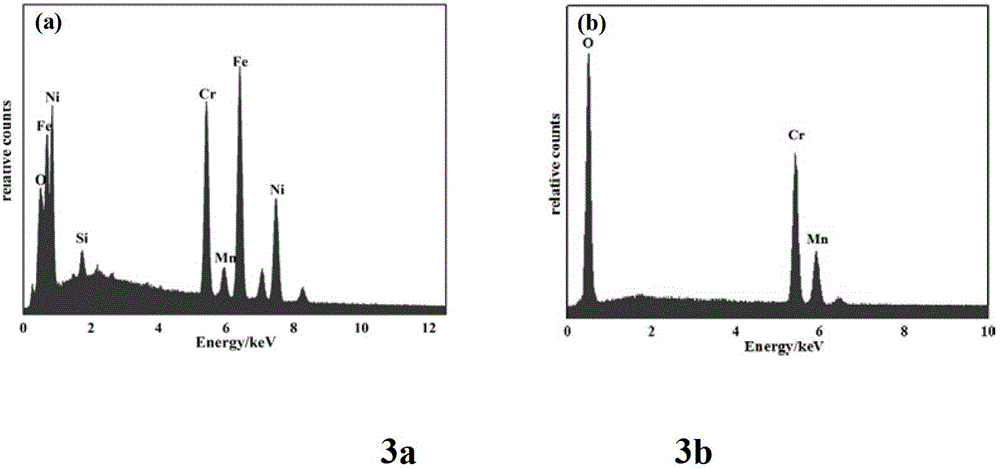

[0035] After oxidation treatment, a three-layer oxide protective film is formed on the surface of the sample, from the outside to the inside: MnCr 2 o 4 Spinel protective layer, Cr 2 o 3 Repair laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com