Alloy material of long carbon chain nylon and polymethylmethacrylate and preparation method thereof

A polymethyl methacrylate and alloy material technology, applied in the field of alloy materials, to achieve the effect of expanding the application field, excellent wear resistance and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

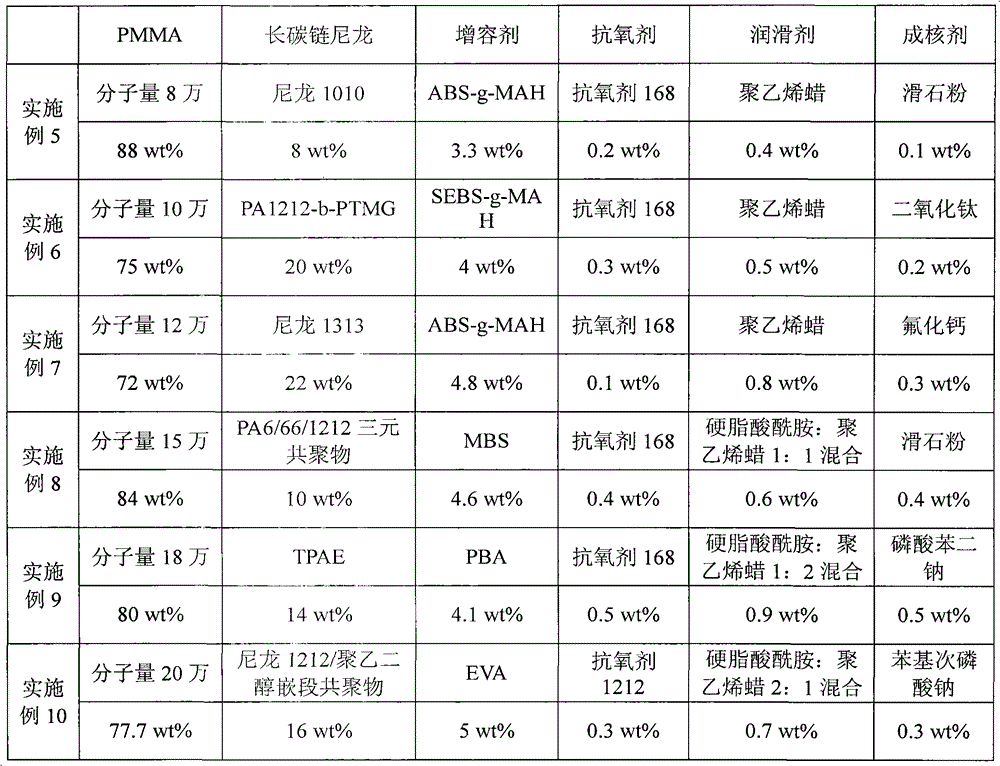

Examples

Embodiment 1

[0028] The composition of the alloy material is:

[0029] PMMA 70wt% with a molecular weight of 70,000;

[0030] Nylon 12122 4wt%;

[0031] Compatibilizer: MBS-g-MAH 5wt%;

[0032] Antioxidant: Antioxidant 1010 0.2wt%;

[0033] Lubricant: stearylamide 0.6wt%;

[0034] Nucleating agent: nano-SiO 2 0.2wt%;

[0035] The preparation process is as follows: the above raw materials are mixed, extruded through a twin-screw extruder at a temperature of 200-230°C, and granulated.

Embodiment 2

[0037] The composition of the alloy material is:

[0038] PMMA 75wt% with a molecular weight of 70,000;

[0039] Nylon 1212 19wt%;

[0040] Compatibilizer: MBS-g-MAH 5wt%;

[0041] Antioxidant: Antioxidant 1010 0.2wt%;

[0042] Lubricant: stearamide 0.6wt%;

[0043] Nucleating agent: nano-SiO 20.2wt%;

[0044] The preparation process is as follows: the above raw materials are mixed, extruded through a twin-screw extruder at a temperature of 200-230°C, and granulated.

Embodiment 3

[0046] The composition of the alloy material is:

[0047] PMMA 80wt% with a molecular weight of 100,000;

[0048] Nylon 1212 14wt%;

[0049] Compatibilizer: MBS-g-MAH 5wt%;

[0050] Antioxidant: Antioxidant 1010 0.2wt%;

[0051] Lubricant: stearylamide 0.6wt%;

[0052] Nucleating agent: nano-SiO 2 0.2wt%;

[0053] The preparation process is as follows: the above raw materials are mixed, extruded through a twin-screw extruder at a temperature of 200-230°C, and granulated.

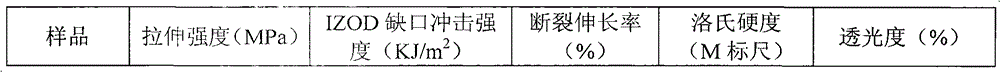

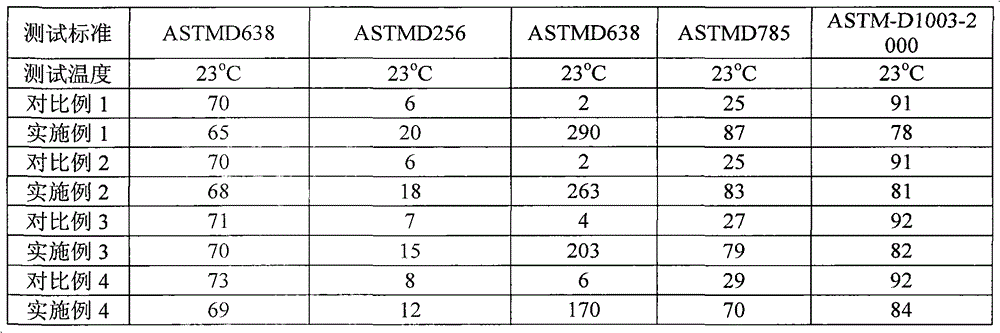

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com