Method for preparing hydrogenated petroleum resin

A technology for hydrogenating petroleum resin and petroleum resin, which is applied in the field of preparation of hydrogenated petroleum resin, can solve the problems of decreased compatibility and increased resin saturation, and achieves the effects of improving compatibility, increasing activity and facilitating technology popularization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

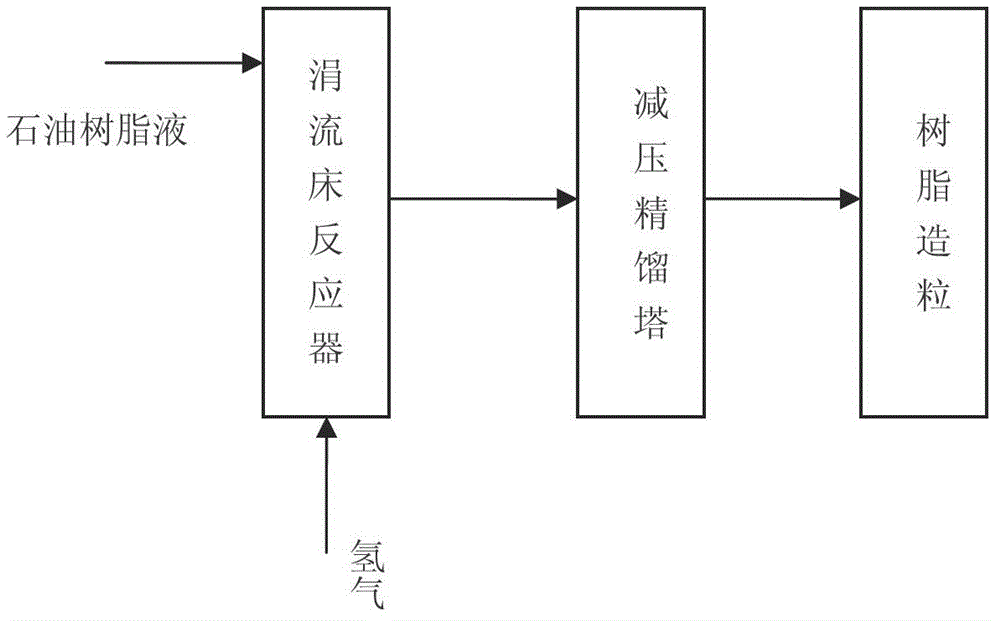

Method used

Image

Examples

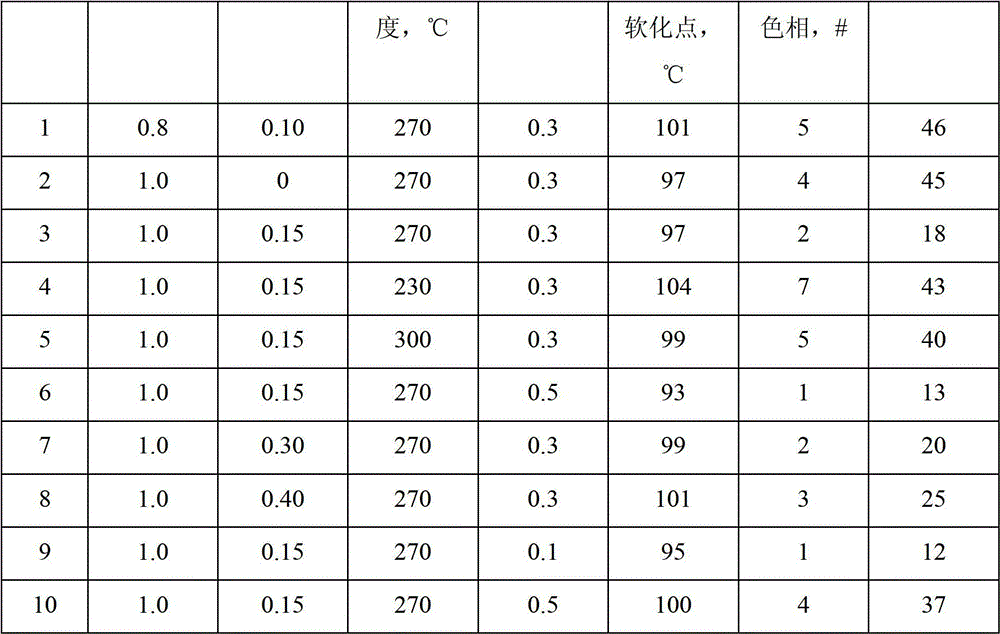

Embodiment 1

[0034] Mix C5 petroleum resin with a Gardner hue of 7 and a softening point of 105°C with hydrocracked aviation kerosene with a boiling point of 200-240°C in a mass ratio of 1:6, then fully dissolve and preheat to 130°C to obtain petroleum resin liquid. The above-mentioned resin liquid and hydrogen are transported into a trickle bed reactor with a fixed bed of hydrogenation catalyst, and the hydrogenation reaction is carried out in the presence of a modified Pd catalyst. The hydrogenation temperature is 270 ° C, the reaction hydrogen pressure is 15.0 MPa, and the reaction space velocity is 0.3h -1 . The active component of the catalyst is Pd, its mass content is 1.0%, the modifier ZnS content is 0.15% of the catalyst mass, and the carrier is γ-Al 2 o 3 , active Al 2 o 3 The specific surface area is 70m 2 / g, the catalyst mesh is 8×14 mesh, and the bulk density is 0.82%. The above-mentioned petroleum resin liquid after hydrogenation is desolventized and oligomers through...

Embodiment 2

[0036]Mix C9 petroleum resin with a Gardner hue of 6 and a softening point of 120°C with hydrocracked aviation kerosene with a boiling point of 200-240°C in a mass ratio of 1:7, fully dissolve, and preheat to 130°C to obtain petroleum resin liquid. The above-mentioned resin liquid and hydrogen are transported into a trickle bed reactor with a fixed bed of hydrogenation catalyst, and the hydrogenation reaction is carried out in the presence of a modified Pd catalyst. The hydrogenation temperature is 280 ° C, the reaction hydrogen pressure is 15.0 MPa, and the reaction space velocity is 0.3h -1 . The active component of the catalyst is Pd with a mass content of 1.05%, the modifier ZnS content is 0.30% of the catalyst mass, and the carrier is γ-Al 2 o 3 , active Al 2 o 3 The specific surface area is 110m 2 / g, the catalyst mesh is 8×14 mesh, and the bulk density is 0.72%. The above-mentioned petroleum resin liquid after hydrogenation, the solvent and oligomers are removed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com