Method for making 1,1-difluoroethylene polymer

A technology for the production of difluoride ethylene, which is applied in 1 field, can solve problems such as complicated polymerization operation, increased equipment cost burden, temperature rising above the critical temperature, etc., and achieves the effects of high bulk density and easy scale coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] Hereinafter, examples are given to further describe the present invention in detail, but the present invention is not limited to the examples.

[0062] The physical properties of the vinylidene fluoride polymer powders obtained in Examples and Comparative Examples were measured by the following methods.

[0063] 〔Inherent viscosity〕

[0064] 4 g of 1,1-vinylidene fluoride polymer powder was added to 1 liter of N,N-dimethylformamide, and a solution was prepared for dissolving at 80° C. for 8 hours. This solution was kept at 30° C., the logarithmic viscosity was measured with an Ubbelohde viscometer, and the inherent viscosity was obtained from the following formula. Logarithmic viscosity [η] = ln (η rel ) / C

[0065] Among them, η rel Indicates the number of falling seconds of the sample solution / the number of falling seconds of the solvent, and C represents the concentration of the sample solution (0.4g / dl).

[0066] 〔SEM observation〕

[0067] The 1,1-vinylidene fl...

Embodiment 1

[0083] 1024g of ion-exchanged water, 0.4g of methylcellulose, 0.2g of sorbitan trioleate (span85, referring to the following formula (1)), 400g of 1,1- Ethylene difluoride, 0.6 g of diisopropyl peroxydicarbonate (IPP), and 1.8 g of ethyl acetate were subjected to suspension polymerization at 26° C. for 31 hours. The polymerization yield of the suspension polymerization was 89%.

[0084] After the polymerization, the polymer slurry was heat-treated at 95°C for 30 minutes, dehydrated, washed with water, and dried at 80°C for 20 hours to obtain vinylidene fluoride polymer powder (1).

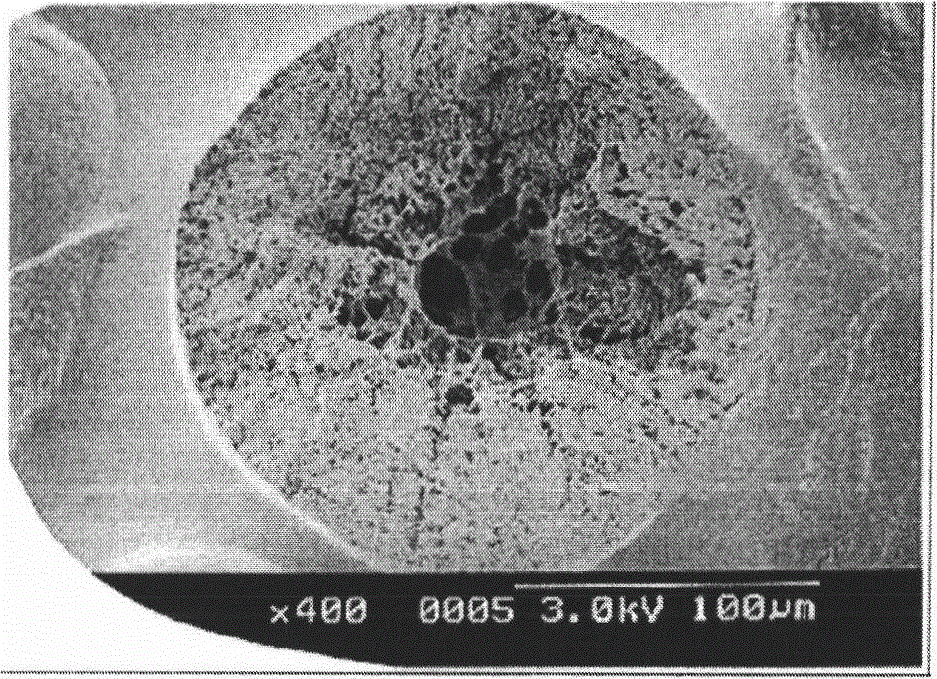

[0085] The obtained 1,1-difluoroethylene polymer powder (1) had an inherent viscosity of 3.1 dl / g, an average particle diameter of 150 μm, and a bulk density of 0.46 g / cm 3 . In addition, the SEM photograph of the cross section of the vinylidene fluoride polymer powder (1) is shown in figure 2 .

[0086]

Embodiment 2

[0088] 1024g of ion-exchanged water, 0.2g of methyl cellulose, 0.4g of sorbitan trioleate (span85), 400g of 1,1-difluoroethylene, 0.6g of peroxide were put into an autoclave with an inner volume of 2 liters. Diisopropyl dicarbonate (IPP), 1.8 g of ethyl acetate, and suspension polymerization at 26° C. for 79 hours. The polymerization yield of the suspension polymerization was 89%.

[0089] After the polymerization, the polymer slurry was heat-treated at 95°C for 30 minutes, dehydrated, washed with water, and dried at 80°C for 20 hours to obtain vinylidene fluoride polymer powder (2).

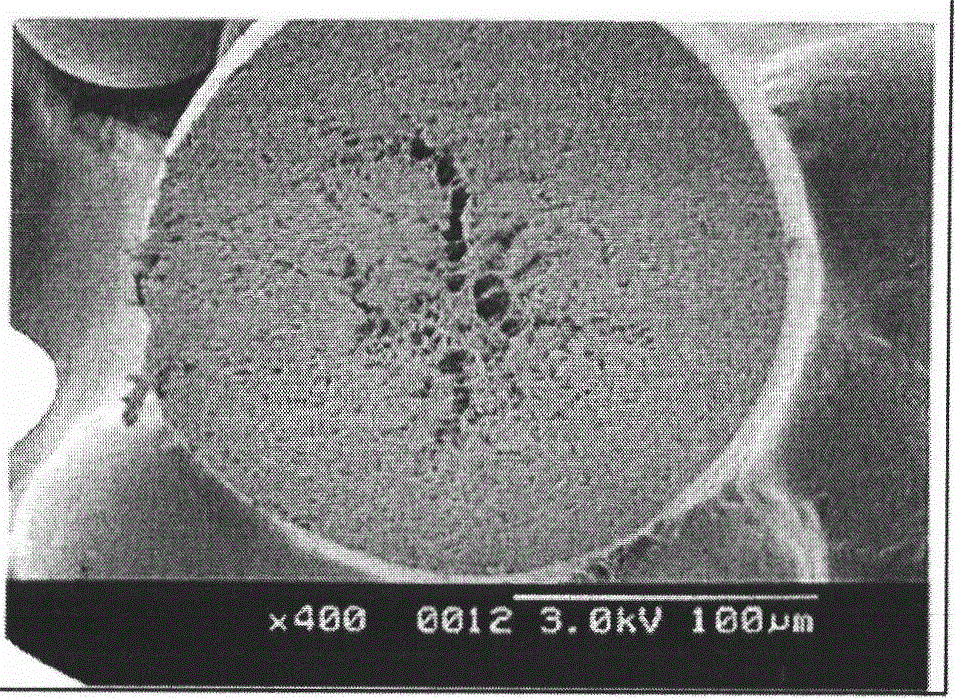

[0090] The obtained 1,1-difluoroethylene polymer powder (2) had an inherent viscosity of 3.1 dl / g, an average particle diameter of 220 μm, and a bulk density of 0.53 g / cm 3 . In addition, the SEM photograph of the cross section of 1,1-vinylidene fluoride polymer powder (2) is shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com