Carbazochrome sodium sulfonate compound and composition thereof

A technology of sodium carbosulfonate and compounds, applied in the field of medicine, to achieve the effect of reducing the possibility, simplifying the prescription, and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

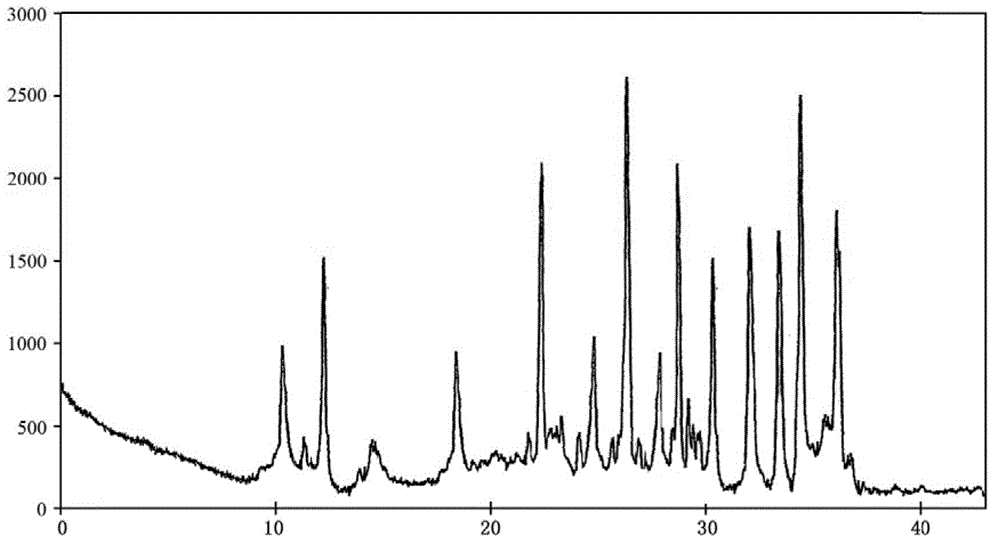

Image

Examples

Embodiment 1

[0051] The sodium carnosulfonate of the present invention is prepared by the following method:

[0052] (1) Take the crude sodium carnosulfonate, add water with a volume of 4.5 times the weight of the crude sodium carnosulfonate, stir, and gradually increase the temperature from room temperature to 80°C;

[0053] (2) After the crude sodium carbsulfonate is fully dissolved, add 0.3 times the amount of active carbon of the crude sodium sulfonate to decolorize and filter;

[0054] (3) Add dropwise to the filtrate a volume of 4.5 times the weight of the crude sodium carnosulfonate and a 16:1 ethanol:chloroform mixed solution; the mixed solution is dripped at a uniform speed within 16 minutes at a stirring speed of 12rpm, While dripping, the temperature of the filtrate was reduced to 12°C at a rate of 1°C / min;

[0055] (4) Stop stirring, cool the solution to 3°C within 10 minutes, leave it to stand for 24 hours, filter, wash twice with 6 times the amount of 70% ethanol aqueous solution, an...

Embodiment 2

[0058] (1) Take the crude sodium carnosulfonate, add water whose volume is 3 times the weight of the crude sodium carnosulfonate, stir, and gradually increase the temperature from room temperature to 75℃;

[0059] (2) After the crude sodium carbsulfonate is fully dissolved, add 0.2 times the amount of activated carbon of the crude sodium sulfonate to decolorize and filter;

[0060] (3) Add dropwise to the filtrate a mixture solution of ethanol:chloroform with a volume ratio of 3 times the weight of the crude sodium carnosulfonate and a volume ratio of 15:1; the mixed solution is dripped at a uniform speed within 8 minutes at a stirring speed of 8rpm, While dripping, the temperature of the filtrate was reduced to 10°C at a rate of 0.5°C / min;

[0061] (4) Stop stirring, cool the solution to 0°C within 5 minutes, leave it to stand for 18 hours, filter, wash twice with 4 times the amount of 60% ethanol aqueous solution, and dry to obtain the sodium calcinate. The yield was 82.9%, and th...

Embodiment 3

[0064] (1) Take the crude sodium carnosulfonate, add water with a volume of 6 times the weight of the crude sodium carnosulfonate, stir, and gradually increase the temperature from room temperature to 85°C;

[0065] (2) After the crude sodium carbsulfonate is fully dissolved, add 0.5 times the amount of active carbon of the crude sodium sulfonate to decolorize and filter;

[0066] (3) To the filtrate, add dropwise a volume of 6 times the weight of the crude sodium carnosulfonate to an ethanol:chloroform mixed solution with a volume ratio of 18:1; the mixed solution is dripped at a uniform speed within 24 minutes at a stirring speed of 16rpm, While dripping, cool the filtrate to 15℃ at a rate of 1.5℃ / min;

[0067] (4) Stop stirring, cool the solution to 5°C within 15 minutes, leave it to stand for 36 hours, filter, wash twice with 8 times the amount of 80% ethanol aqueous solution, and dry to obtain the sodium sulphonate. The yield was 83.4%, and the HPLC content was 99.76%.

[0068] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com