Cold-ironing type gold stamping technology and gold stamping mechanism thereof

A cold stamping, process technology, applied in the printing process, printing machine, gold powder printing and other directions, can solve the problems affecting the hot stamping fastness and the sharpness of graphic and text outlines, high cost of template input, shrinkage, etc., to improve the printing effect and Print quality, lower input costs, the effect of significant technological progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

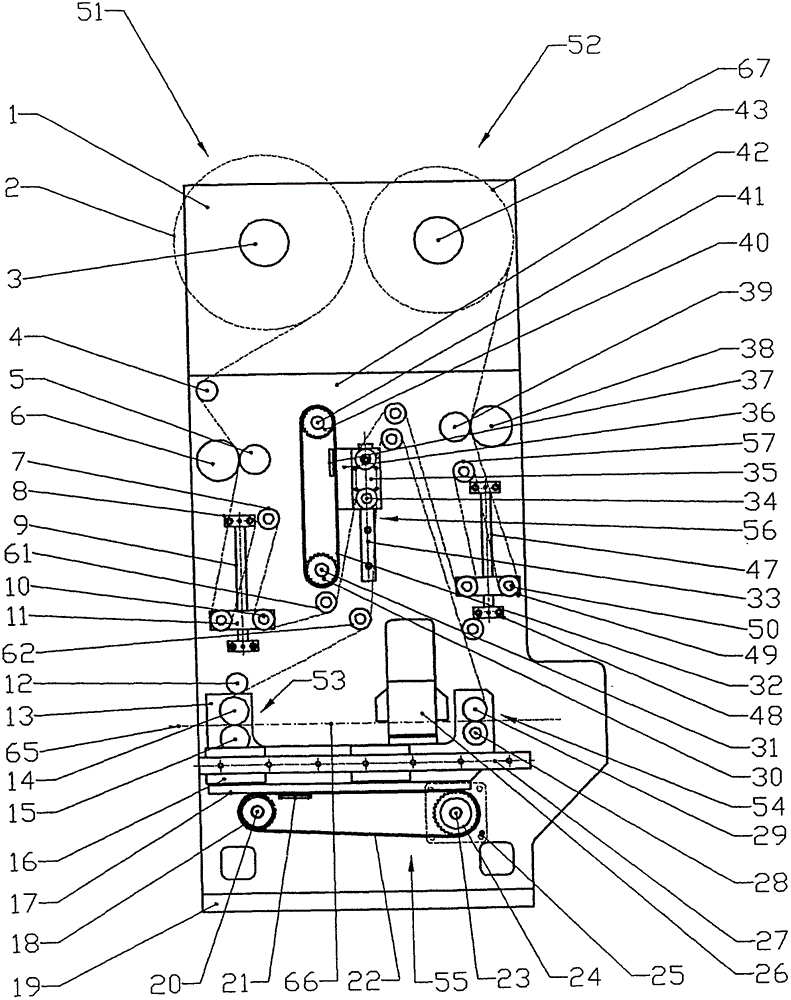

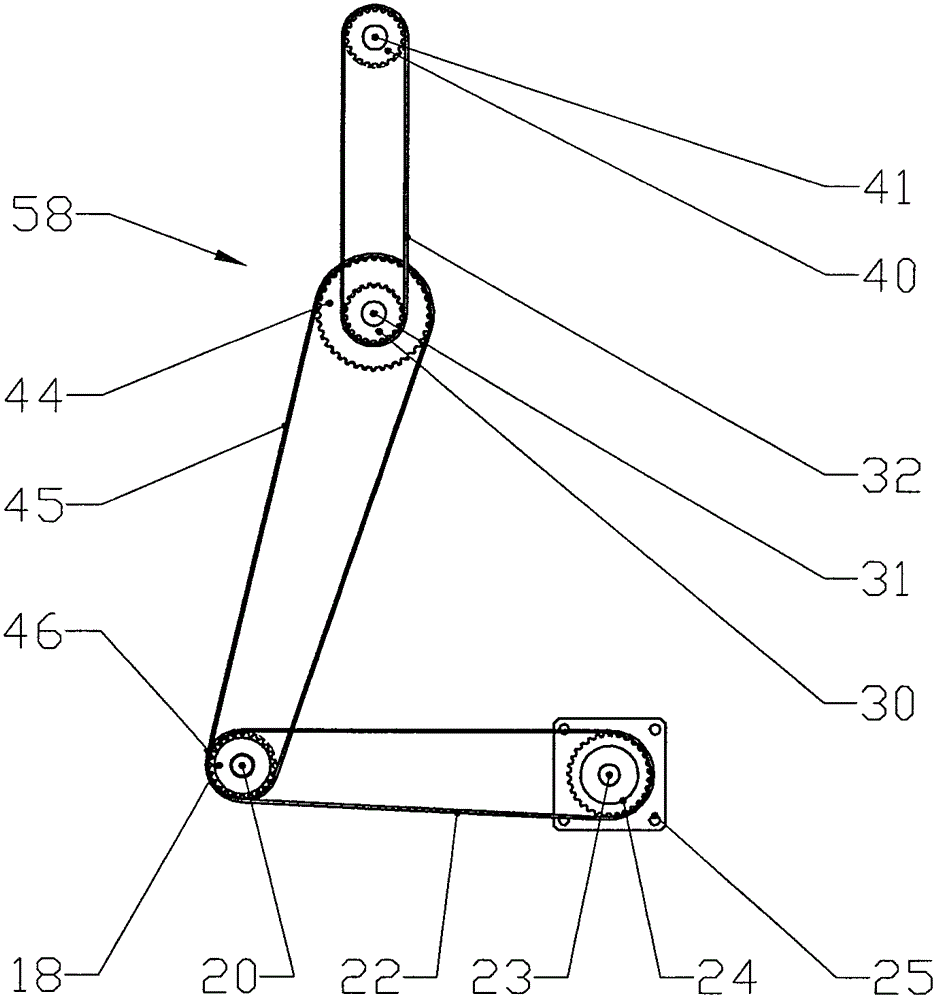

[0011] The cold stamping bronzing process applied on the printing and packaging of the present invention is: firstly, the required graphics and texts are printed on the printing materials by the offset printing of the PS template, and (by the feeding mechanism) on the graphics and texts of the printing materials Apply a layer of glue (the glue used in known offset printing cold stamping, the thickness of which is added or subtracted by the printing master based on experience and hot stamping effect); then, the printed material coated with a layer of glue (on its graphic) (in the lower layer) and the aluminum foil material (on the upper layer) are processed by circular rolling lamination, ultraviolet light box irradiation, and circular rolling peeling; due to the rolling lamination between materials and the sticking effect of glue The aluminum foil is printed on the corresponding graphics of the printing material, and then through the ultraviolet light curing effect of the ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com