Silicone ejection oil pressure molding machine

A molding machine and silica gel technology, which is applied in the field of silicone injection hydraulic molding machines, can solve the problems of low efficiency, high labor intensity of workers, unfavorable mass mechanized production, etc., and achieve the effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

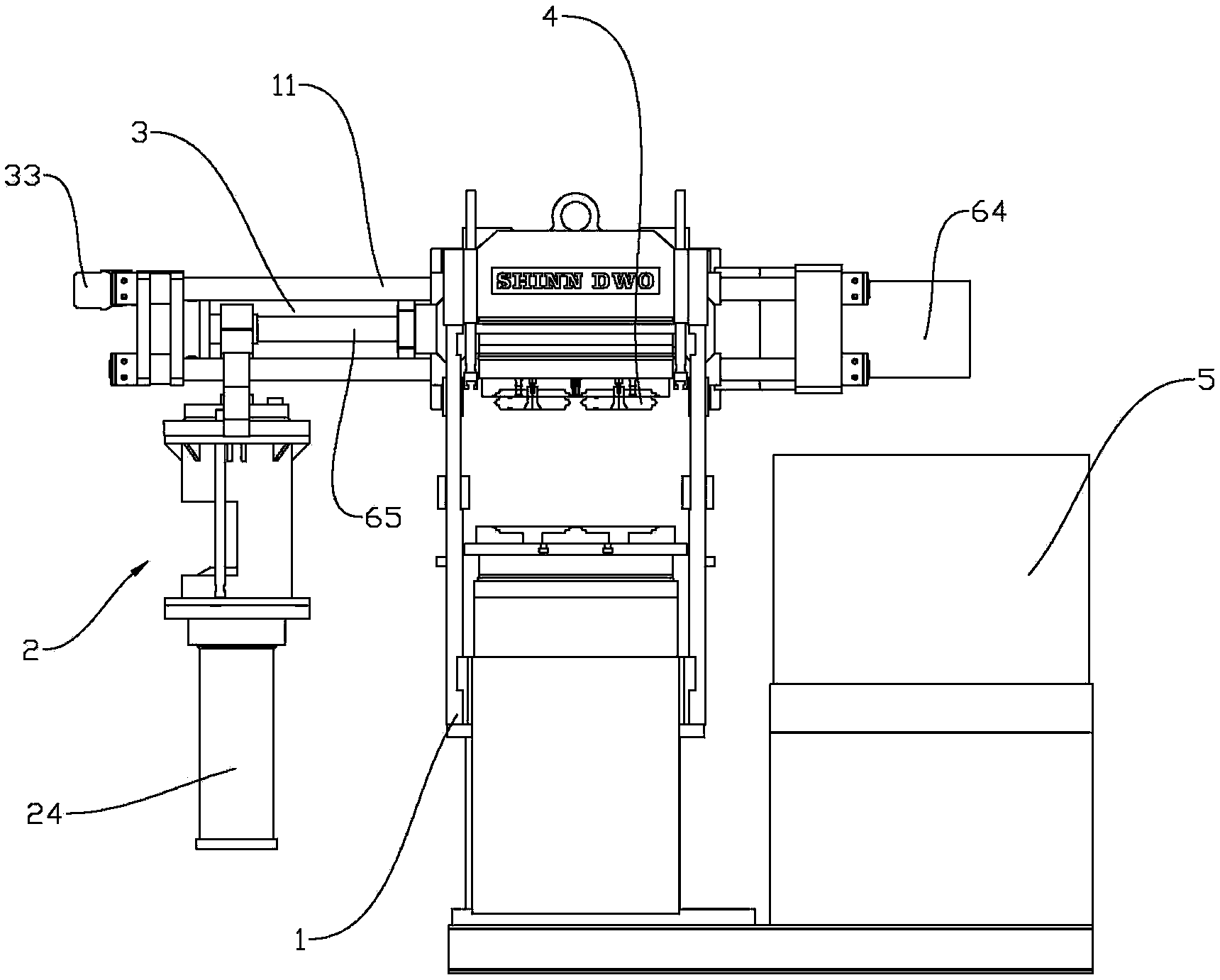

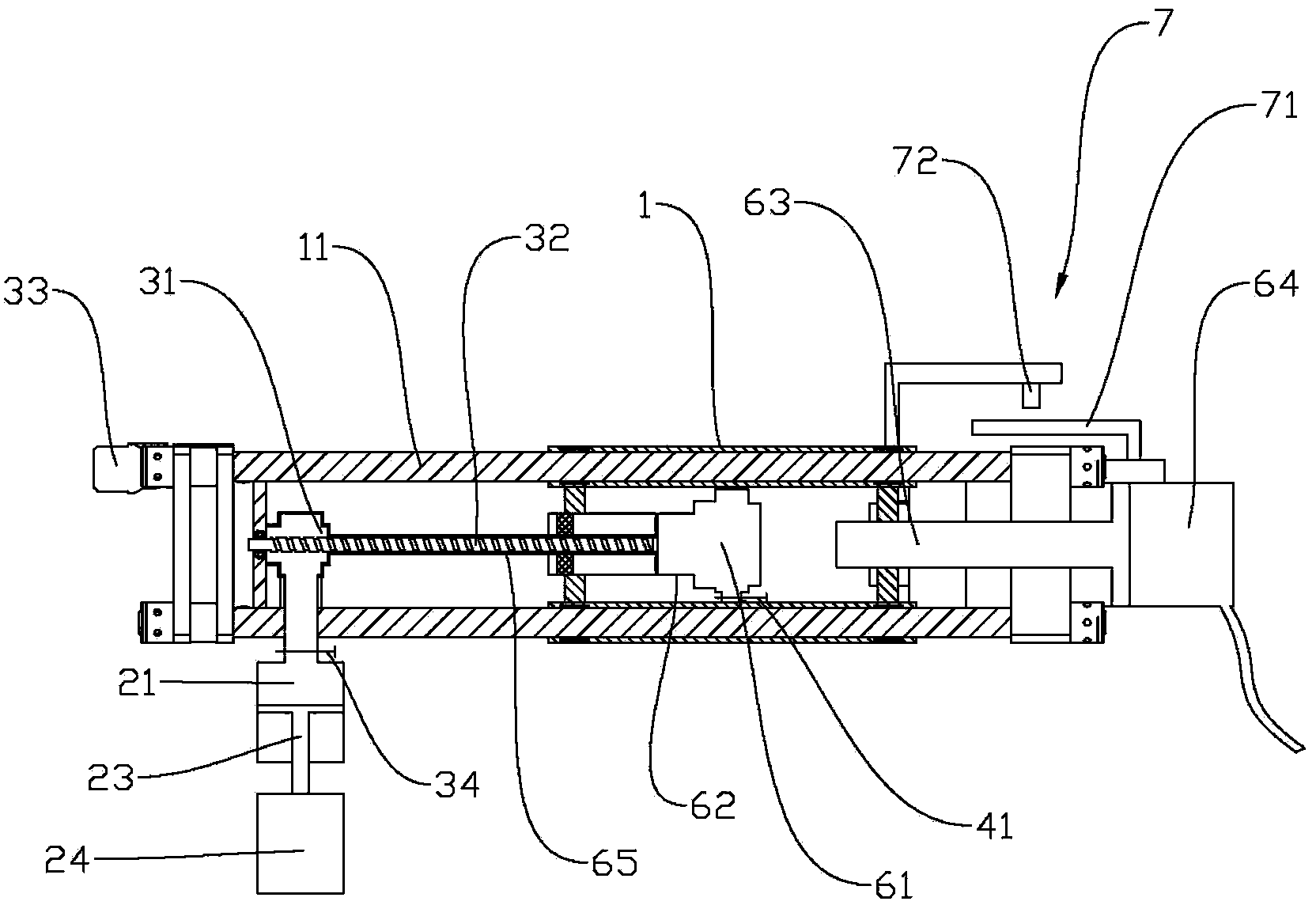

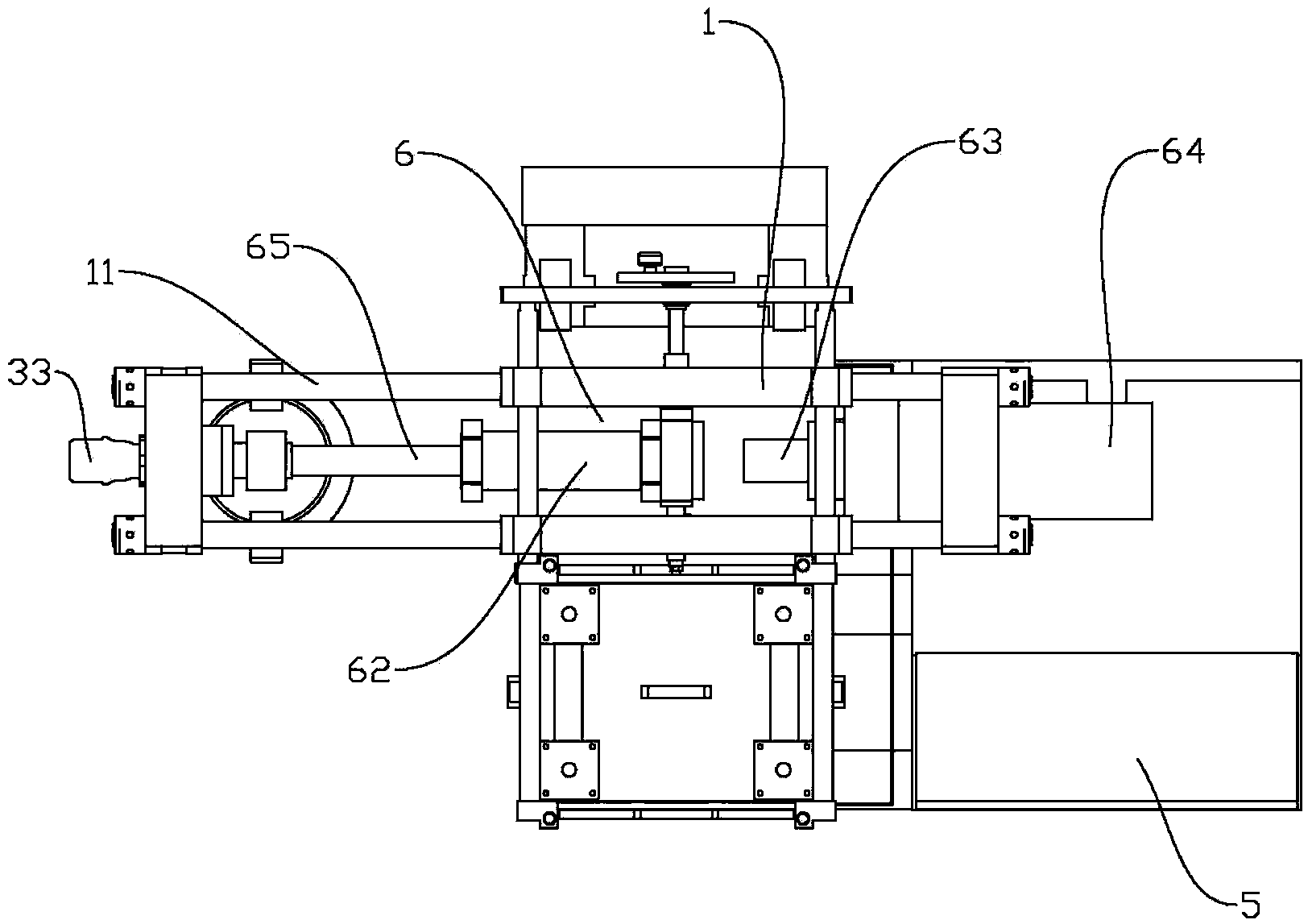

[0016] Reference Figure 1 ~ Figure 3 , The present invention is a silicone injection hydraulic molding machine, including a frame 1, a storage device 2, a feeding device 3, a molding die 4, a control device 5, and a power supply. The storage device 2 is provided with a first cavity 21, The feeding device 3 is provided with a channel 31, and the first cavity 21 is in communication with the channel 31. It also includes a precision injection device 6. The precision injection device 6 is provided with a second cavity 61. One end of the second cavity 61 is in communication with the channel 31. One end is communicated with the injection hole of the molding die 4, and the precise injection device 6 is provided with a monitoring device 7 for monitoring the injection amount of silica gel. The present invention adopting the above structure can carry out precise injection by itself by using the precise injection device 6 to realize the automation of the entire production process of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com