Lens mold core

A lens and mold core technology, which is applied in the field of lens mold cores for manufacturing optical lenses, can solve the problems affecting the accuracy of the upper mold base, easy to appear bell mouth, deep glue position, etc., to improve processing accuracy, good exhaust performance, and guarantee The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

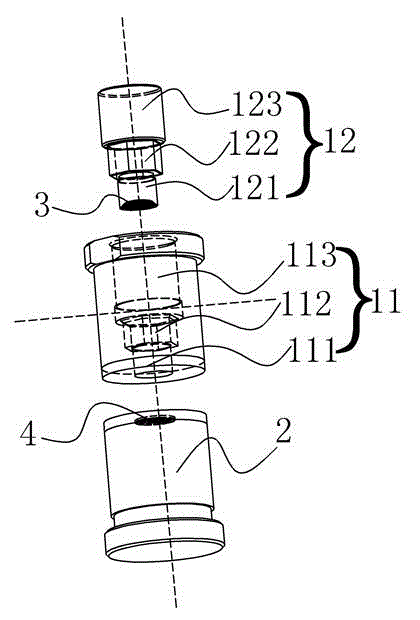

[0015] figure 1 and figure 2 A lens mold core according to an embodiment of the present invention is schematically shown.

[0016] The lens mold core includes an upper mold base 1 and a lower mold base 2 . The upper end of the lower mold base 2 is provided with a lower lens groove 4 . The upper mold base 1 includes a bushing part 11 and a sub-mould core 12 nested by the bushing part 11 .

[0017] A first positioning hole 111 , a second positioning hole 112 and a third positioning hole 113 are disposed inside the nesting component. The sub-mould core 12 includes a first positioning post 121 , a second positioning post 122 and a third positioning post 123 , and the first positioning post 121 , the second positioning post 122 and the third positioning post 123 are integrally formed. The first positioning column 121 is a cylindrical structure, the first pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com