Pore-free tire segmental mould and pattern block thereof

A tire flexible mould, no air hole technology, applied in tires, household utensils, other household utensils, etc., can solve the problems of increasing mold manufacturing process, time consumption, and increasing mold manufacturing cost, so as to achieve simple machining, ensure appearance quality, The effect of good exhaust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

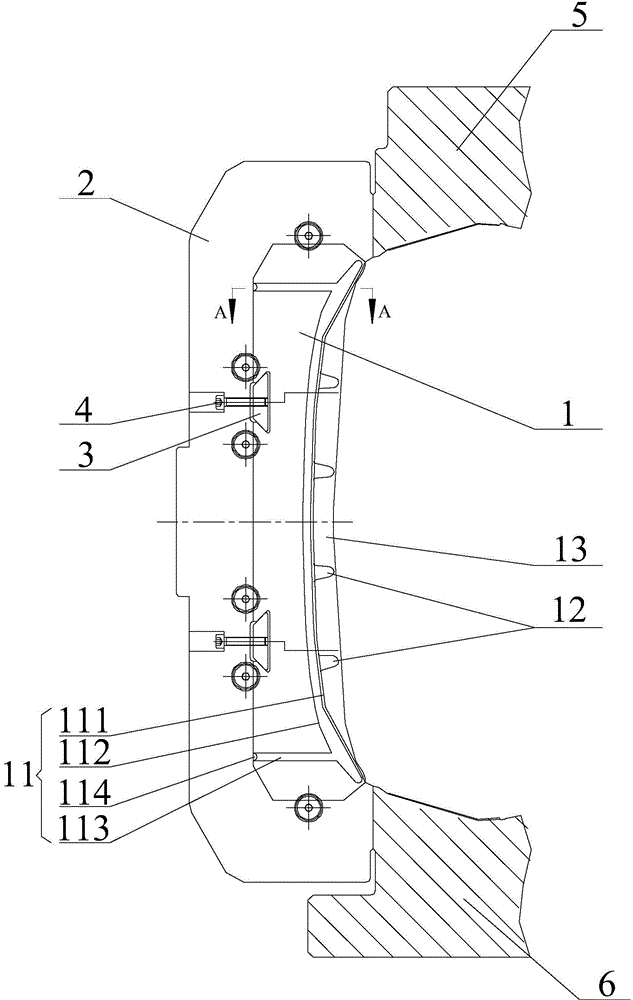

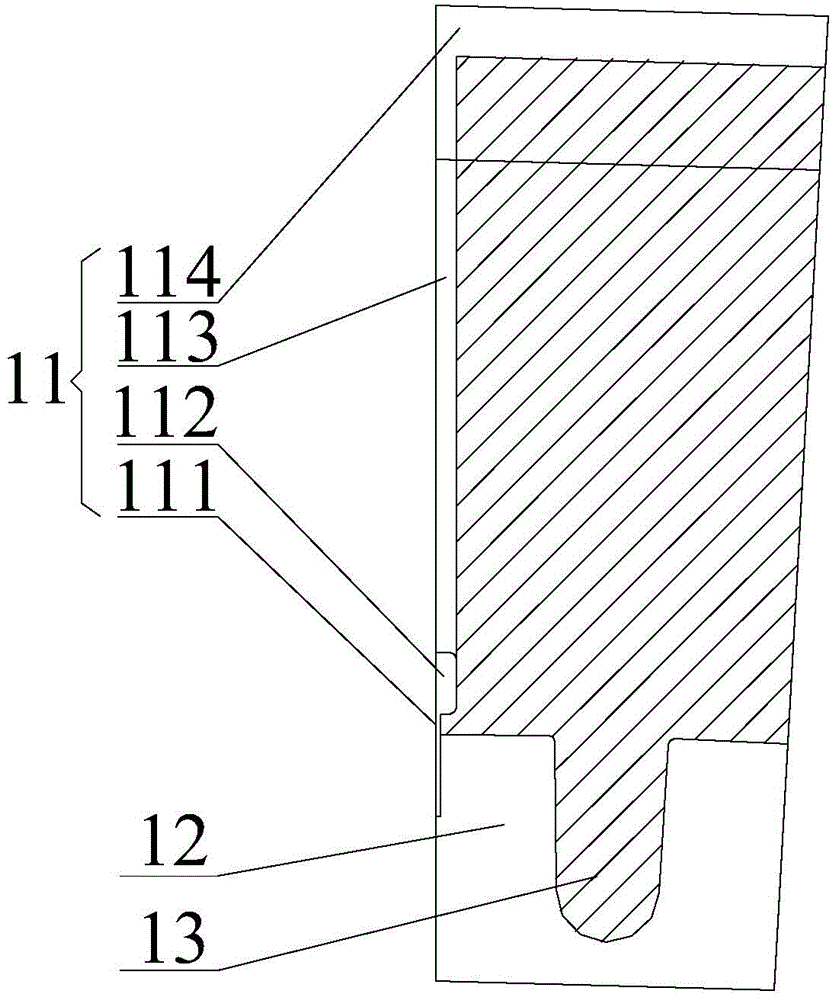

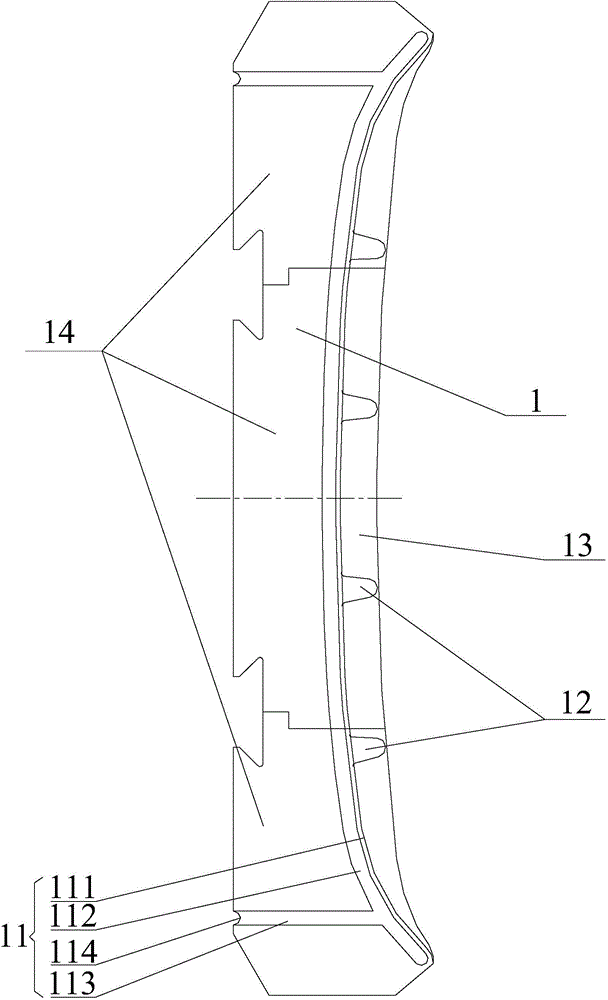

[0042] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0043] Such as Figure 1 ~ Figure 2 As shown, the present invention provides a pattern block of a non-porous tire flexible mold, wherein the pattern block of a non-porous tire flexible mold includes a plurality of pattern pieces 1 and a pattern pattern shell 2, and the plurality of pattern pieces 1 are arranged and assembled along the circumferential direction And form an annular structure capable of accommodating rubber blanks (i.e., tire blanks) for tire building, that is, the radial cross-section of each pattern piece 1 is in the shape of a sector tapered from the outside of the annular structure to the inside of the annular structure, and the annular structure is formed when the tire is formed. In direct contact with the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com