Lead-free soft braze welding material and preparation method of lead-free soft braze welding material

A technology of soldering and manufacturing method, applied in welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problems of easy peeling of solder joints, high bismuth content, high price, reduce slag production rate, protect Metal surface, simple effect of manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

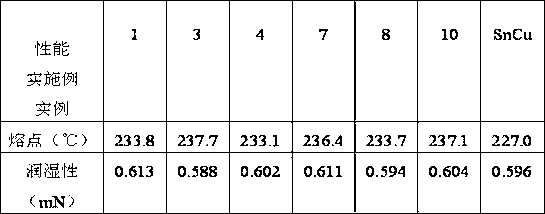

Examples

Embodiment 1

[0030] Add 90kg of refined tin into a graphite crucible for melting, heat up to 1100°C after melting, add 10kg of refined copper, stir evenly with a wooden stirring rod and melt into a liquid tin-copper alloy, then pour it into a mold and cast it into a tin-copper alloy after standing for 30 minutes Ingot removal;

[0031] Then put 50kg of refined tin into the graphite crucible for melting, heat up to 600°C-1000°C after melting, add 50kg of pure antimony, wait for the antimony to melt and stir evenly, pour it into a mold and cast it into a tin-antimony alloy ingot after standing for 30 minutes and take it out;

[0032] Then put 57kg of refined tin into the graphite crucible for melting, heat up to about 1600°C after melting, put in 3kg of pure nickel, wait for the nickel to melt and stir evenly, pour it into a mold and cast it into a tin-nickel alloy ingot after standing for 30 minutes and take it out;

[0033] Three kinds of alloy ingots prepared above, active carbo...

Embodiment 2

[0035] Get three kinds of alloy ingots prepared in Example 1, activated carbon and tin to be formulated by weight percentage: antimony: 4.8%, copper: 0.1%, nickel: 3.0%, activated carbon: 0.5% and the balance are tin lead-free solder .

Embodiment 3

[0037] Get three kinds of alloy ingots prepared in Example 1, activated carbon and tin to be formulated by weight percentage: antimony: 6.0%, copper: 2.5%, nickel: 1.5%, activated carbon: 0.3% and the balance are the lead-free solder of tin .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com