Low-silver lead-free solder and preparation method thereof

A lead-free solder and raw material technology, used in welding equipment, welding/cutting media/materials, welding media, etc., can solve the problem of high cost of eutectic alloys, achieve grain refinement, ensure long-term reliability, and improve wetting performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

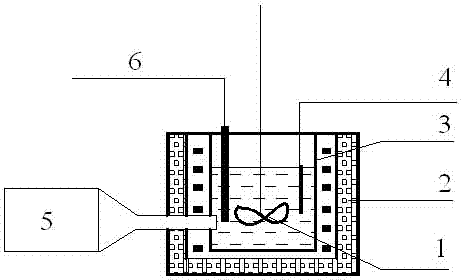

Method used

Image

Examples

Embodiment Construction

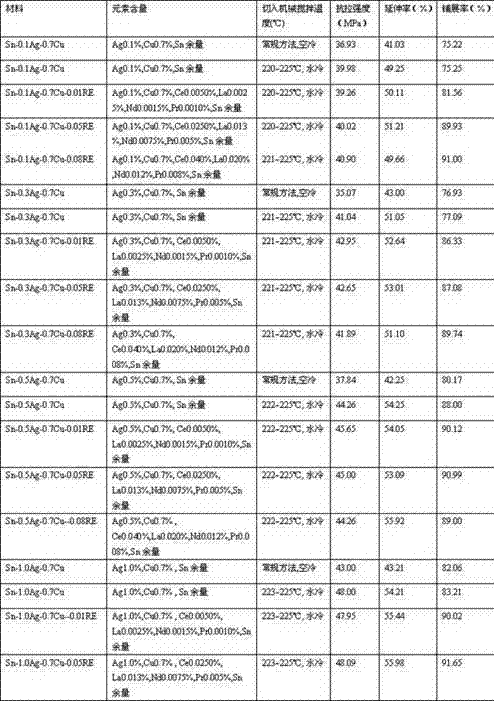

[0023] According to the above preparation method of the present invention, the components and properties of the prepared solder alloy and their comparison are shown in the following table. It can be seen from the table below that the temperature range of alloy solder cutting into mechanical stirring becomes narrower with the increase of silver content in the alloy. Using semi-solid cutting into strong mechanical stirring, combined with ultrasonic vibration, can eliminate dendrite formation and improve the plasticity of solder. The addition of rare earths has little effect on the tensile strength and elongation, but an appropriate amount of mixed rare earths can improve the wettability of the alloy.

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com