Steel plate blanking blocking device

A blocking device and blanking technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of impact layer damage, falling off, and lower production efficiency, so as to reduce the use cost, prevent impact deformation, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

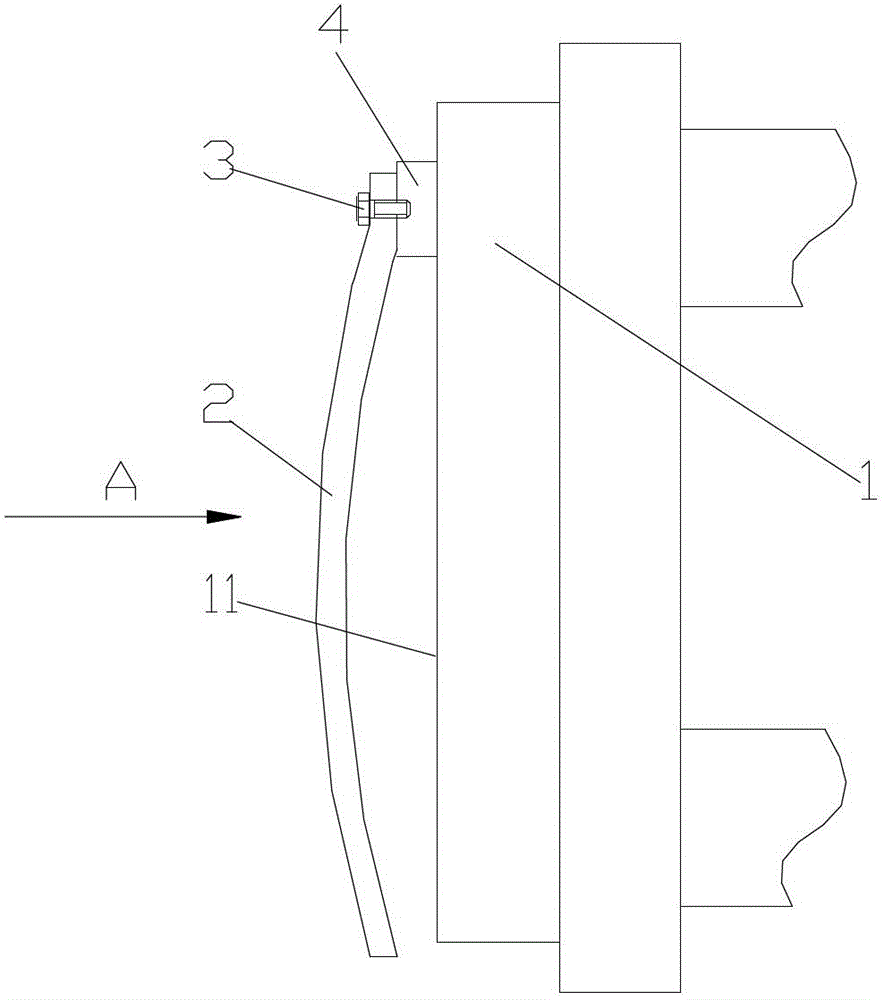

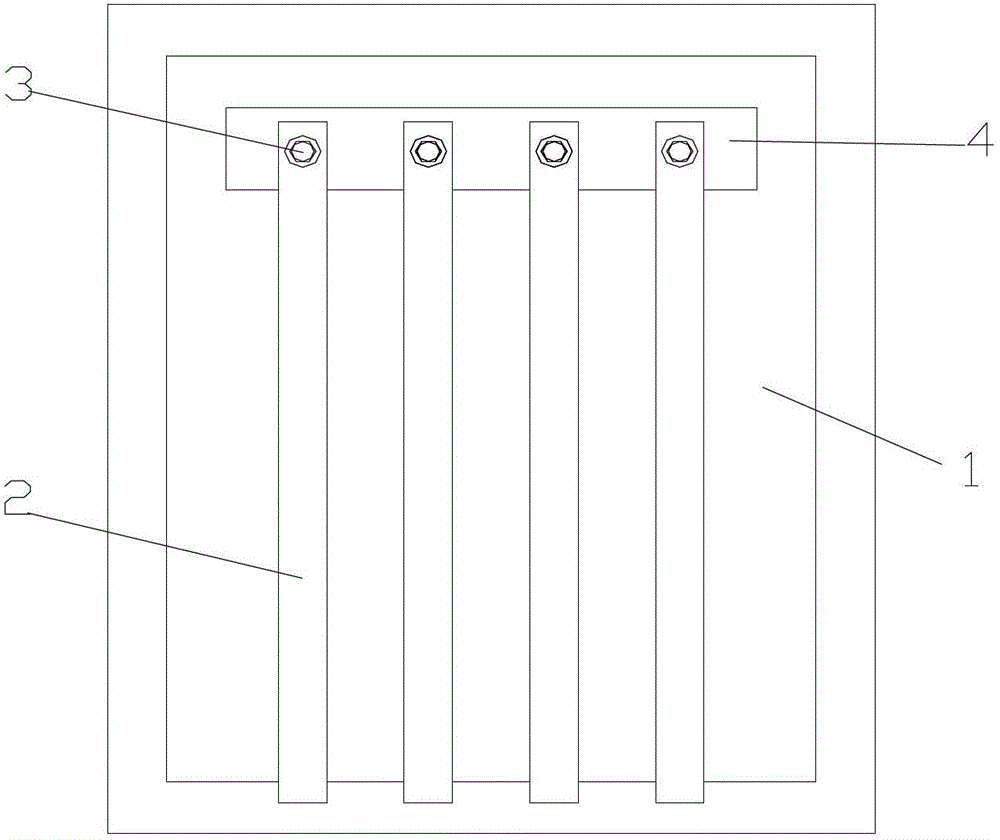

[0018] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 View along the A direction, as shown in the figure: the steel plate blanking blocking device of this embodiment includes a vertically fixed base plate 1, generally fixedly set on the frame of the unit for cutting steel plates, and the base plate 1 faces the incoming material The direction is provided with a working surface 11 for blocking and letting the incoming material fall. The working surface 11 is provided with a buffer assembly that can produce elastic buffer deformation under the impact of the incoming material. The buffer assembly can adopt a structure such as a leaf spring or a spring. The cushioning will also effectively unload the impact force of the steel plate, ensure the stability of the substrate installation, and thus ensure the smooth progress of the stacking process.

[0019] In this embodiment, the buffer assembly includes a leaf spring 2 and a moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com