Method for producing cold-rolled sheet for surface coating and plating base plate

A cold-rolled sheet and production method technology, applied in coating, metal rolling, hot-dip plating, etc., can solve the problems of poor surface quality, inability to meet the requirements of high-end customers, color difference, etc., and achieve excellent formability, excellent Surface quality and coating performance, bright and clean surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

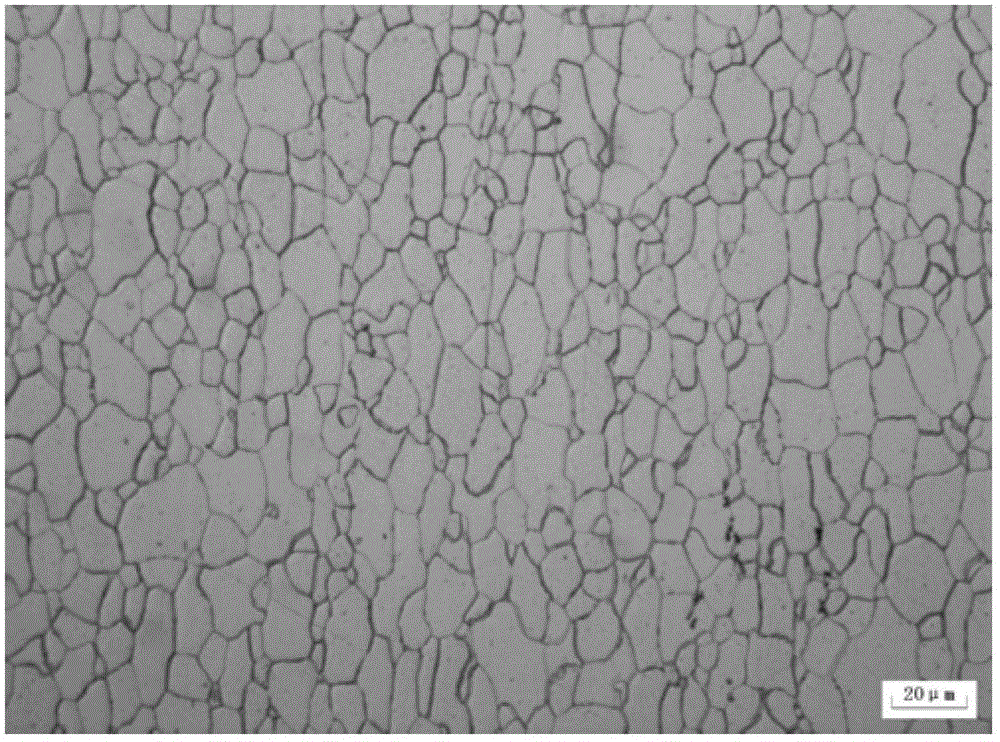

Image

Examples

Embodiment 1

[0038]The mass percentages of steel billets used are: C, 0.12%; Si, 0.050%; Mn, 0.60%; P, 0.040%; S, 0.04%; the balance is Fe.

[0039] The tapping temperature is 1280°C, the exit temperature of rough rolling is 1200°C, the final rolling temperature is 950°C, and the coiling temperature is 750°C.

[0040] Pickling 1# acid tank free acid is controlled at 55g / L, pickling temperature is 90°C, and pickling speed is 200m / min.

[0041] The work rolls of stands 1, 2 and 5 of the rolling mill use chrome-plated rolls. The surface roughness Ra of the work rolls of stands 1 and 2 is 0.8 μm, the surface roughness of the work rolls of stands 3 and 4 is 0.7 μm, and the surface roughness of the work rolls of stand 5 is The roughness Ra is 3.0μm; the concentration of the emulsified liquid is 4.5% for racks 1 to 4, and the concentration of the emulsified liquid for racks 5 is 1.5%. Cold rolling reduction rate is controlled at 85%.

[0042] The subsequent process adopts the continuous anneali...

Embodiment 2

[0048] The mass percentages of steel billets used are: C, 0.11%; Si, 0.040%; Mn, 0.50%; P, 0.035%; S, 0.036%, and the balance is Fe.

[0049] The tapping temperature is 1220°C, the exit temperature of rough rolling is 1090°C, the final rolling temperature is 910°C, and the coiling temperature is 710°C.

[0050] Pickling 1# acid tank free acid concentration 5g / L, pickling temperature 75°C, pickling speed 140m / min.

[0051] The work rolls of stands 1, 2, and 5 of the rolling mill use chrome-plated rolls. The surface roughness Ra of the work rolls of stands 1 and 2 is 0.7 μm, the surface roughness of the work rolls of stands 3 and 4 is 0.6 μm, and the surface roughness of the work rolls of stand 5 is The roughness Ra is 3.0μm; the concentration of the emulsified liquid is 2.5% for racks 1 to 4, and the concentration of the emulsified liquid for racks 5 is 0.5%. Cold rolling reduction rate is controlled at 60%.

[0052] The subsequent process adopts the continuous annealing proc...

Embodiment 3

[0058] The mass percentages of steel billets used are: C, 0.09%; Si, 0.040%; Mn, 0.40%; P, 0.030%; S, 0.03%, and the balance is Fe.

[0059] The tapping temperature is 1250°C, the exit temperature of rough rolling is 1105°C, the final rolling temperature is 935°C, and the coiling temperature is 734°C.

[0060] Pickling 1# acid tank free acid is controlled at 53g / L, pickling temperature is 80°C, and pickling speed is 180m / min.

[0061] The work rolls of stands 1, 2 and 5 of the rolling mill use chrome-plated rolls. The surface roughness Ra of the work rolls of stands 1 and 2 is 0.8 μm, the surface roughness of the work rolls of stands 3 and 4 is 0.7 μm, and the surface roughness of the work rolls of stand 5 is The roughness Ra is 3.0μm; the concentration of the emulsified liquid is 4.5% for racks 1 to 4, and the concentration of the emulsified liquid for racks 5 is 1.5%. Cold rolling reduction rate is controlled at 81%.

[0062] The subsequent process adopts the continuous an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com