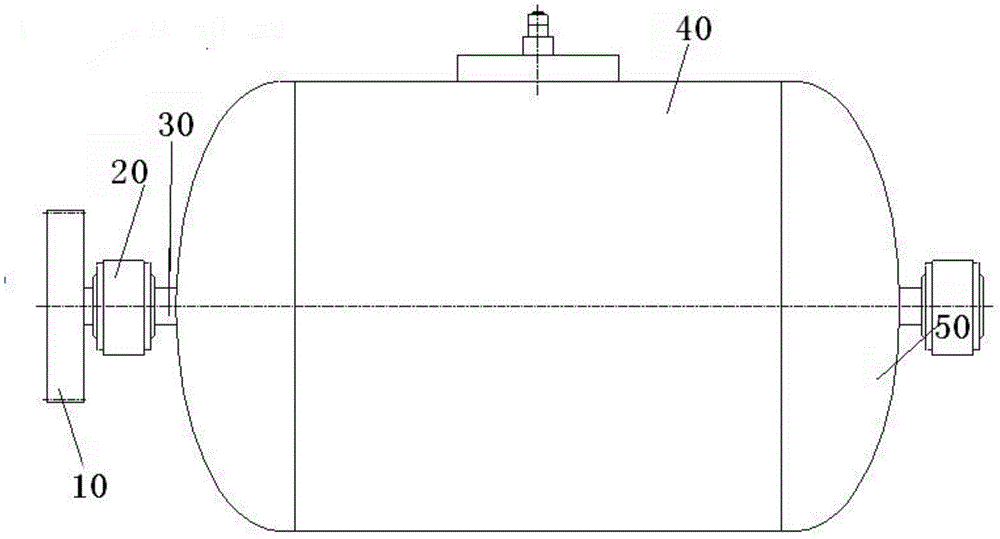

Improved horizontal vessel rotating device

A container rotation, horizontal technology, applied in mixers with rotating containers, chemical/physical/physicochemical mobile reactors, transportation and packaging, etc., can solve the problem of affecting the service life of equipment, affecting production line production, and transmission impact And other problems, to achieve the effect of reducing the number and time of workers' maintenance, low power consumption, and preventing left and right movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

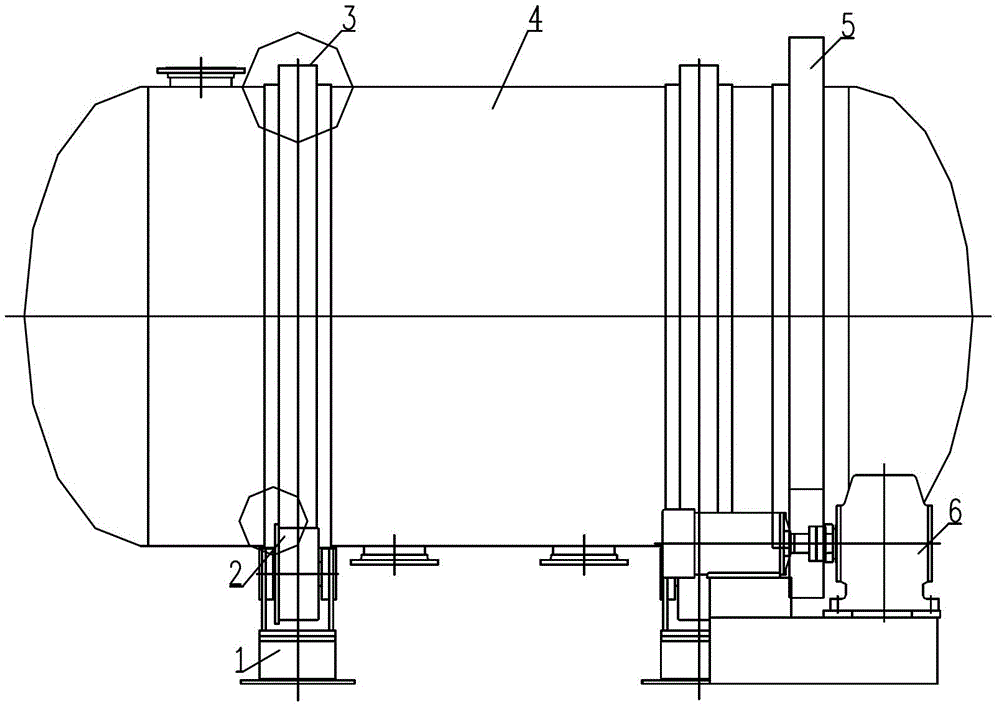

[0022] Embodiment: in insoluble sulfur for rubber and water glass industry, product needs mass production and continuous production. The rotating device runs smoothly and has low noise, which meets the user's requirements for technology and use. A 20m3 vertical reactor with stirring is equipped with a motor power of 37kW, while a 20m3 reactor with an improved horizontal container rotation device is equipped with a motor power of only 15kW, and the energy saving effect is obvious.

[0023] When the rotating device is used to produce solid powder and other products, ideal effects can also be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com