Sensor network long-distance charging and power supplying system based on laser light source

A sensor network and laser light source technology, applied in the field of sensor networks, can solve the problems of wireless sensor networks that are not suitable for random distribution of nodes, difficult long-distance transmission of energy, and attenuation of transmission efficiency, so as to improve remote photoelectric conversion efficiency and output power , high energy transmission efficiency, and the effect of reducing peak brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

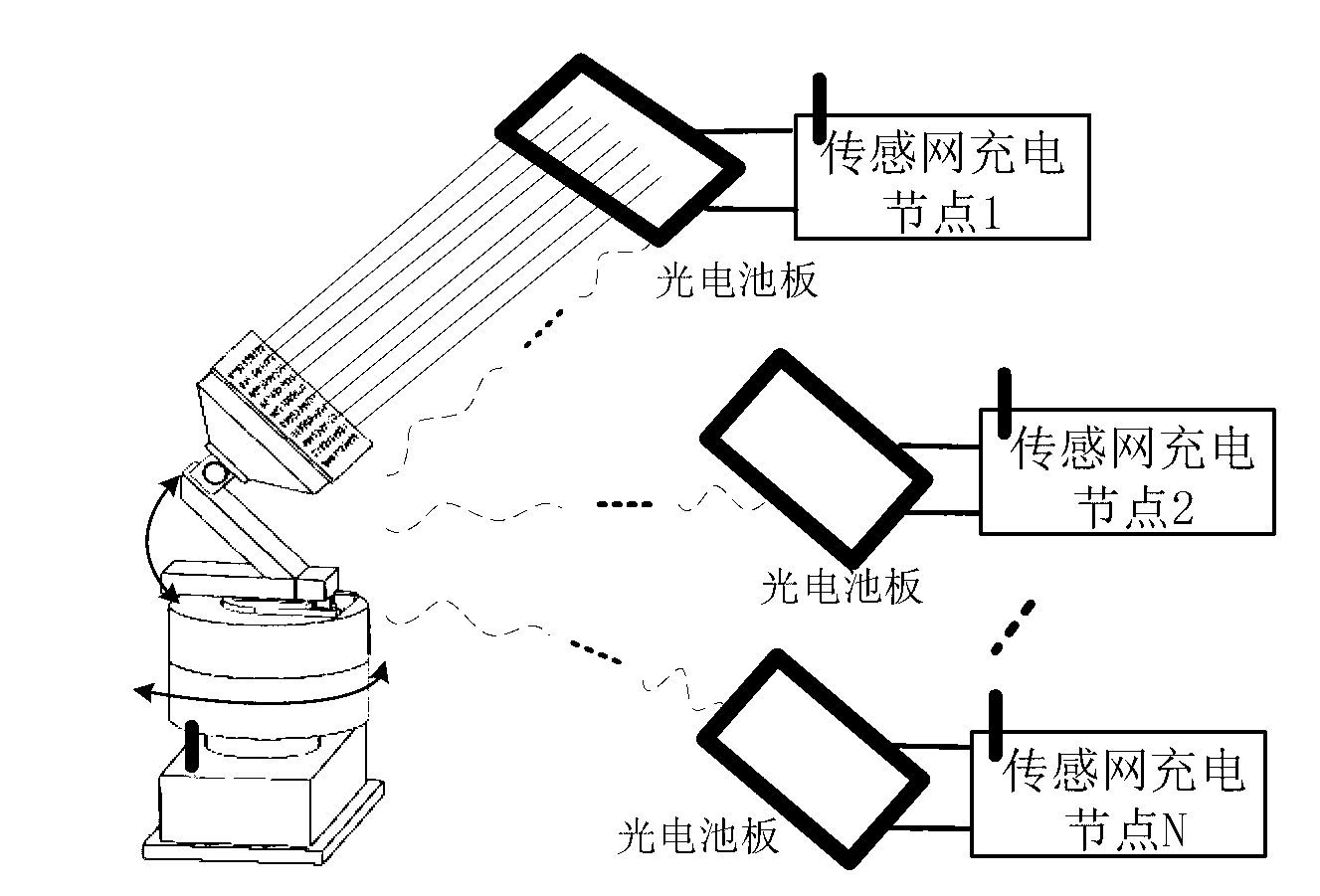

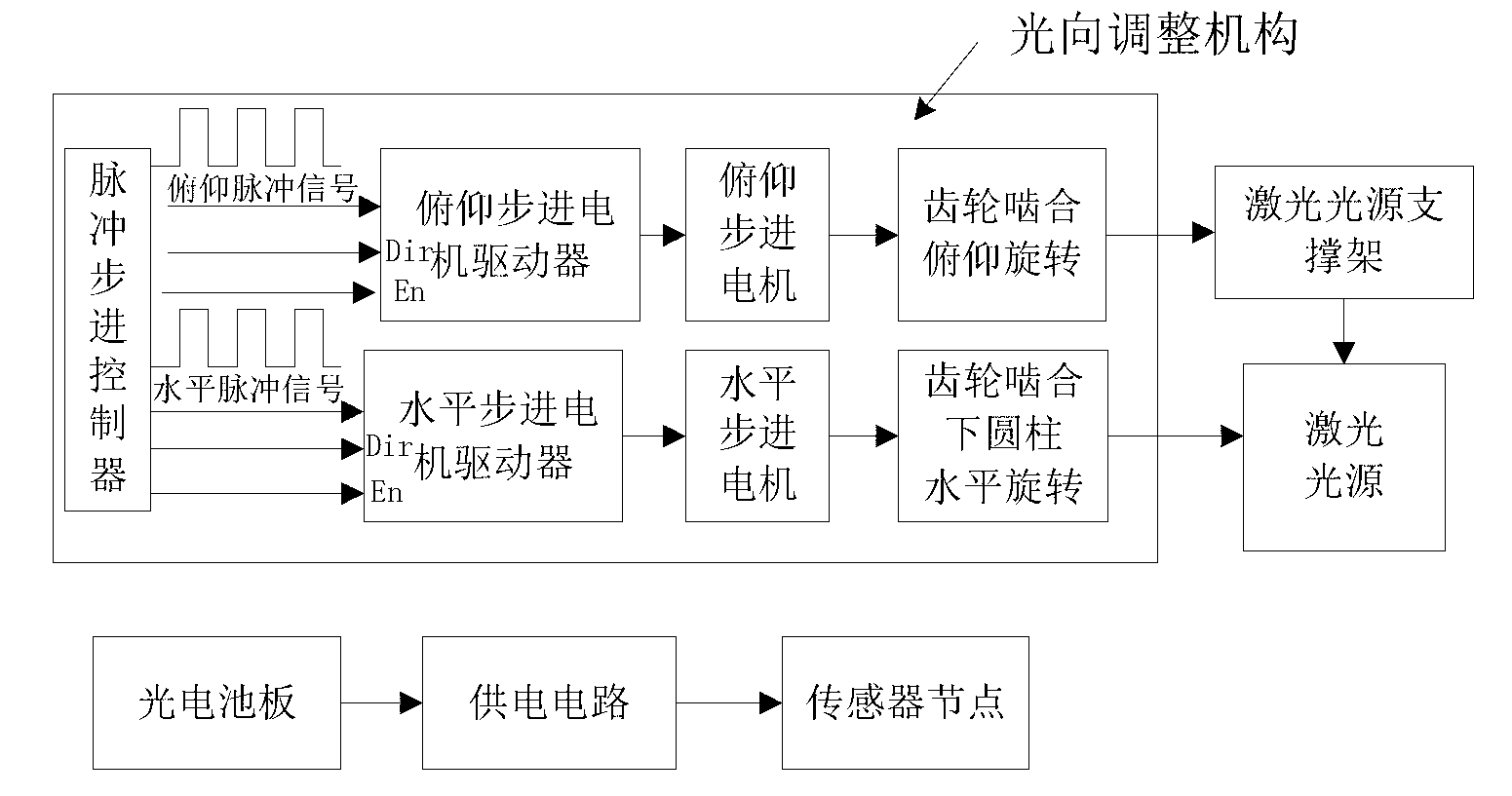

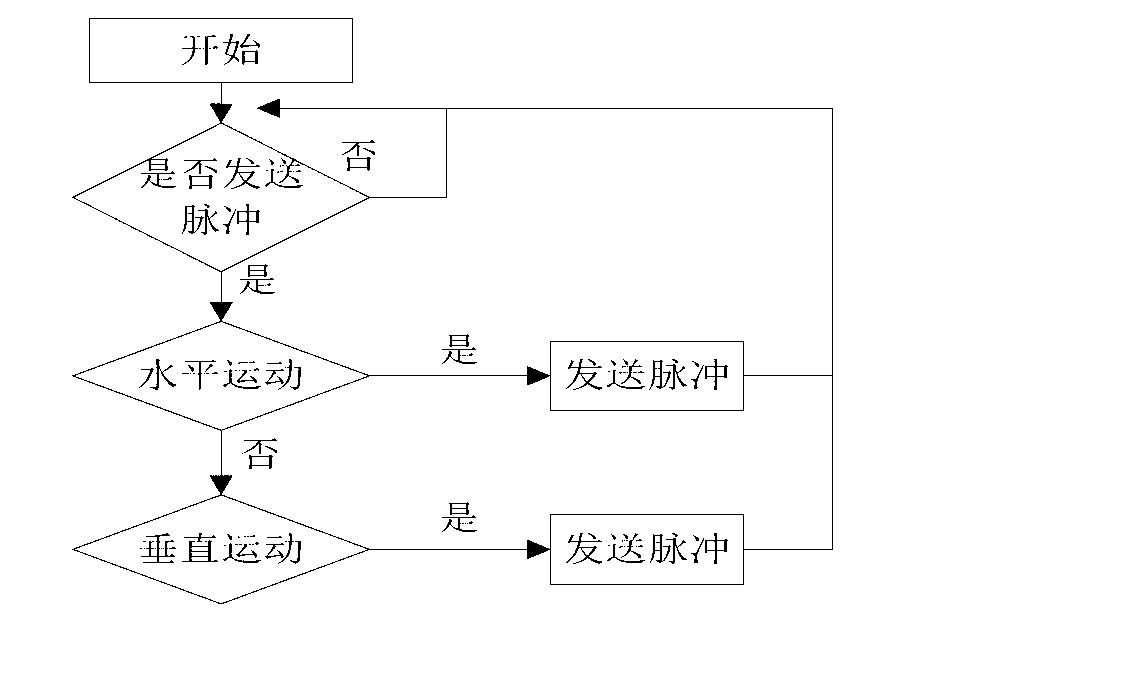

[0032] see figure 1A remote charging and supplying system is composed of a charging and supplying master with a laser light source and a light direction adjustment mechanism and a wireless sensor network node charging and supplying slave composed of multiple sensor networks. see figure 2 and Figure 18 The charging and power supply host includes a laser light source and a light direction adjustment mechanism. The laser light source is N×M laser heads distributed in a rectangular array, and the light directions of each laser head are parallel; the light direction adjustment mechanism includes a pulse stepping controller, a pitch stepping motor, Pitching stepping motor driver, horizontal stepping motor and horizontal stepping motor driver, pulse stepping controller under the command of the controller, respectively output pulse signals to pitching stepping motor driver and horizontal stepping motor driver, pitching stepping motor driver Drive the pitch stepping motor, the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com