Lithium ion battery and cathode thereof

A lithium-ion battery and negative electrode technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of cell deformation and cycle performance, achieve excellent cycle performance, high reversible capacity, and increase the weight of active materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Using high-purity silicon as the silicon source, the amorphous silicon active layer is deposited on the Cu current collector by magnetron sputtering. The thickness of the deposited amorphous silicon active layer is 1 μm; the graphite active layer is coated on the above amorphous silicon active layer. Above, the graphite active layer is composed of graphite active material, conductive additive and binder. The graphite active material in the graphite active layer is a mixture of natural graphite and artificial graphite, and the proportion of natural graphite in the mixture of natural graphite and artificial graphite is 35%. The proportion of the amorphous silicon active layer in the entire negative electrode active material is 2%.

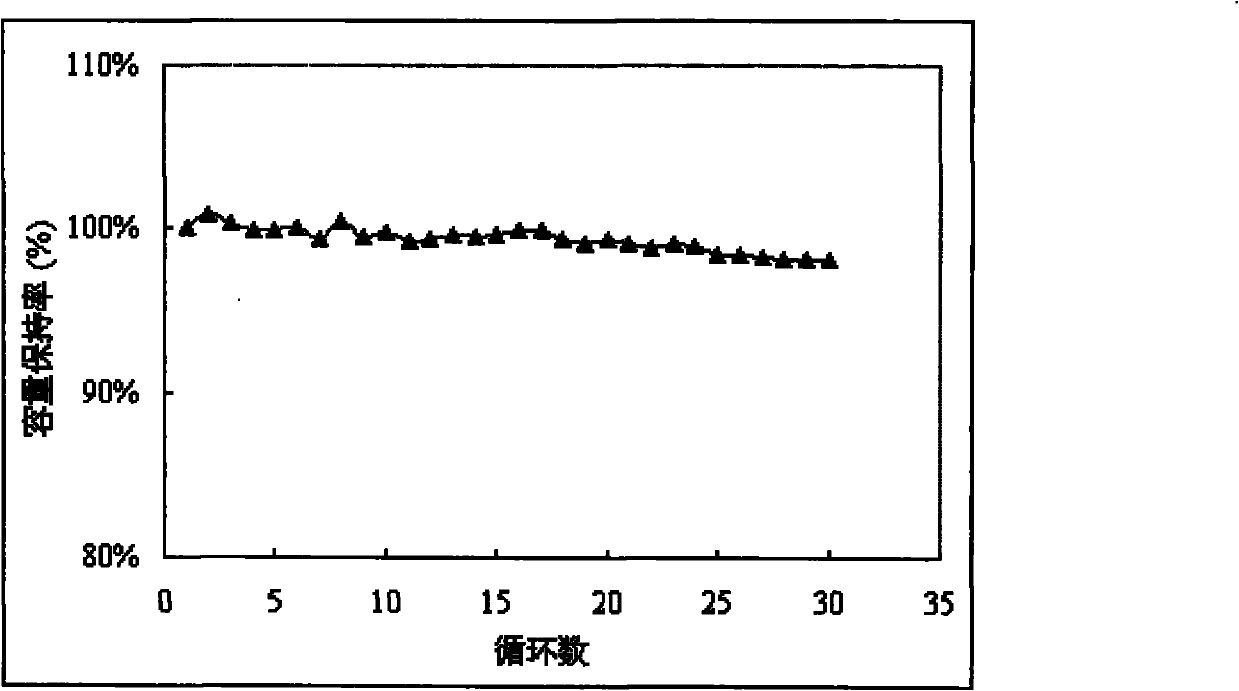

[0031] The initial reversible capacity of the above-mentioned negative electrode measured in the button battery is 391mAh / g, the initial efficiency is 86.8%, and the capacity retention rate after 30 cycles is 96%. The battery cycle curve is a...

Embodiment 2

[0033] Using high-purity silicon as the silicon source, the amorphous silicon active layer is deposited on the Cu current collector by magnetron sputtering. The thickness of the deposited amorphous silicon active layer is 0.2 μm; the graphite active layer is coated on the above amorphous silicon active layer. layer above. The graphite active layer is composed of graphite active material, conductive additive and binder. The graphite active material in the graphite active layer is natural graphite. The proportion of the amorphous silicon active layer in the entire negative electrode active material is 0.5%.

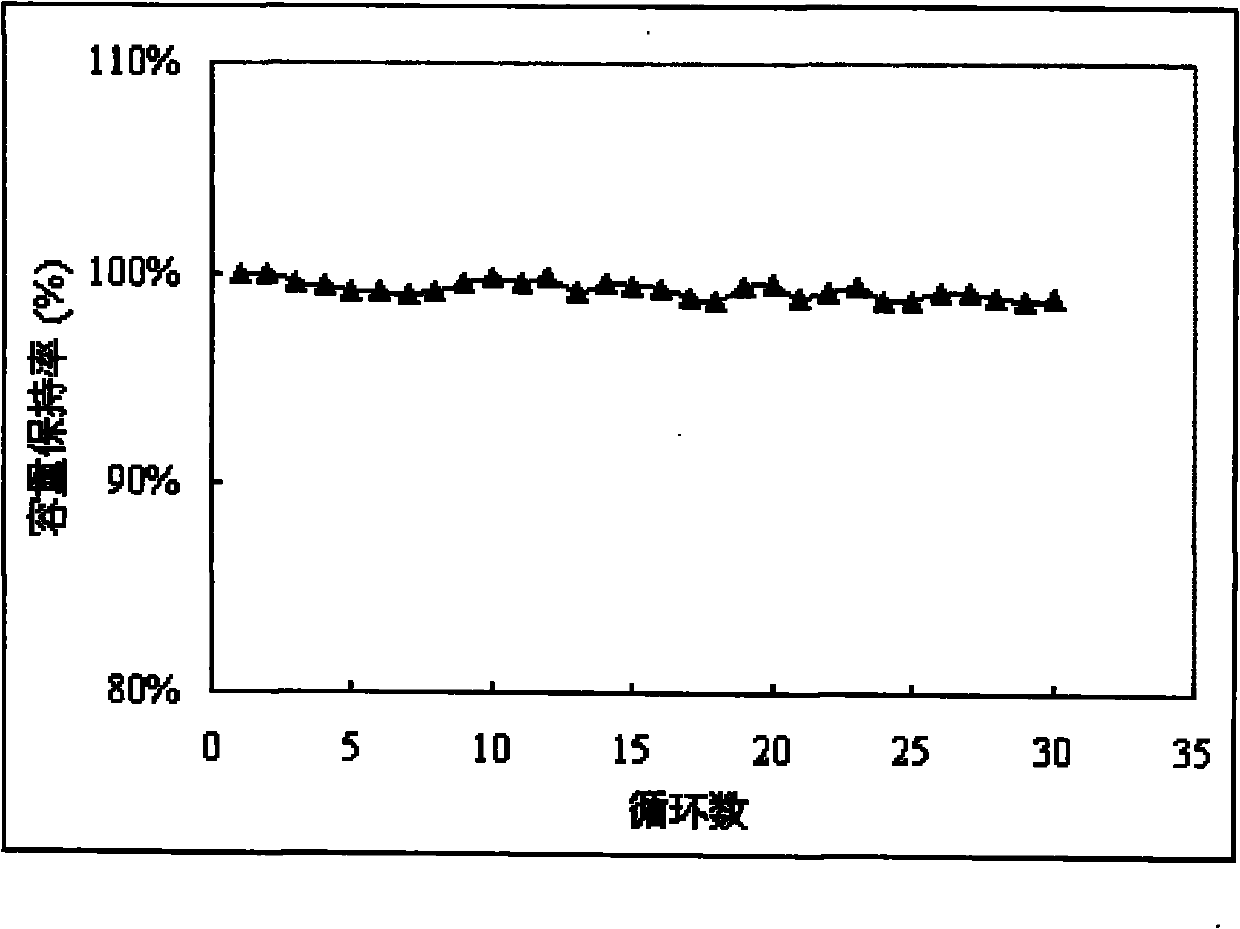

[0034] The initial reversible capacity of the above-mentioned negative electrode measured in the button battery is 354mAh / g, the initial efficiency is 89.2%, and the capacity retention rate after 30 cycles is 98.1%. The battery cycle curve is as figure 2 shown.

Embodiment 3

[0036]Using high-purity silicon as the silicon source, the amorphous silicon active layer is deposited on the Cu current collector by magnetron sputtering. The thickness of the deposited amorphous silicon active layer is 0.5 μm; the graphite active layer is coated on the above amorphous silicon active layer. layer above. The graphite active layer is composed of graphite active material, conductive additive and binder. The graphite active material in the graphite active layer is artificial graphite. The proportion of the amorphous silicon active layer in the entire negative electrode active material is 1%.

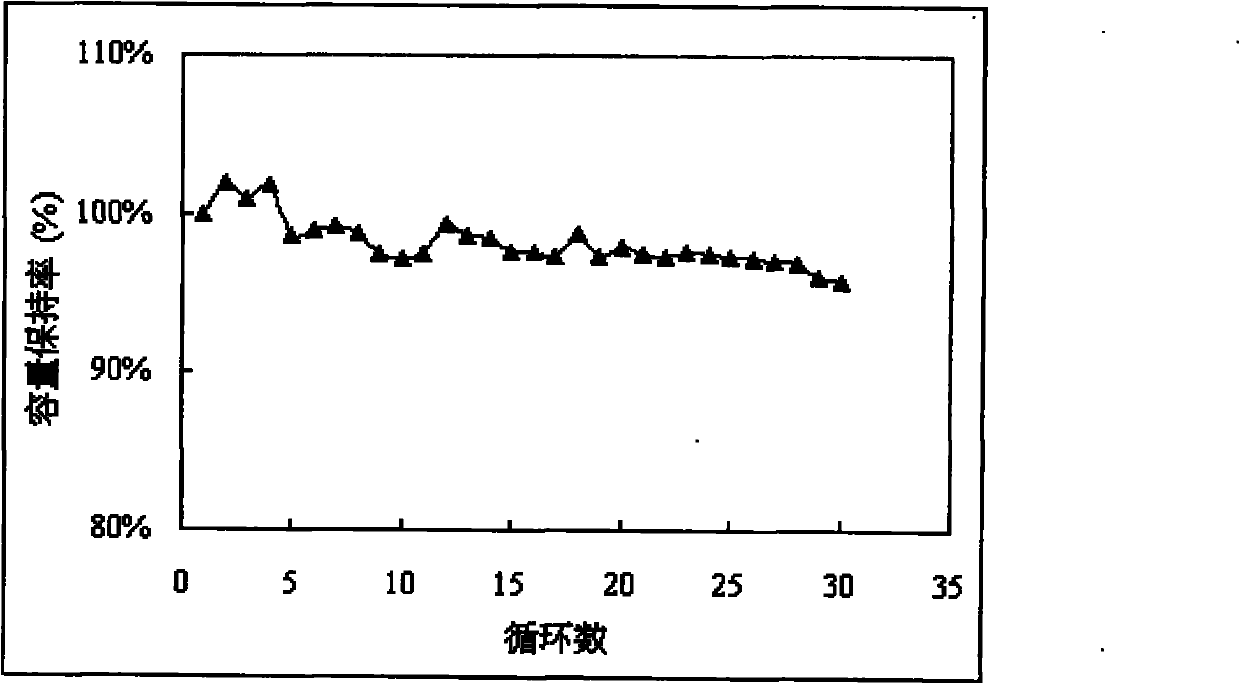

[0037] The initial reversible capacity of the above-mentioned negative electrode measured in the button battery is 365mAh / g, the initial efficiency is 88.3%, and the capacity retention rate after 30 cycles is 96.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com