Gallium arsenide-based geometrical giant magnetoresistance device and preparation method thereof

A gallium arsenide-based, giant magnetoresistance technology, which is applied in the fields of magnetic field-controlled resistors and the manufacture/processing of electromagnetic devices, can solve the problems of complex preparation process, complex structure, and high cost of raw materials, and achieve simple preparation process and environmental protection. Friendly, Affordable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

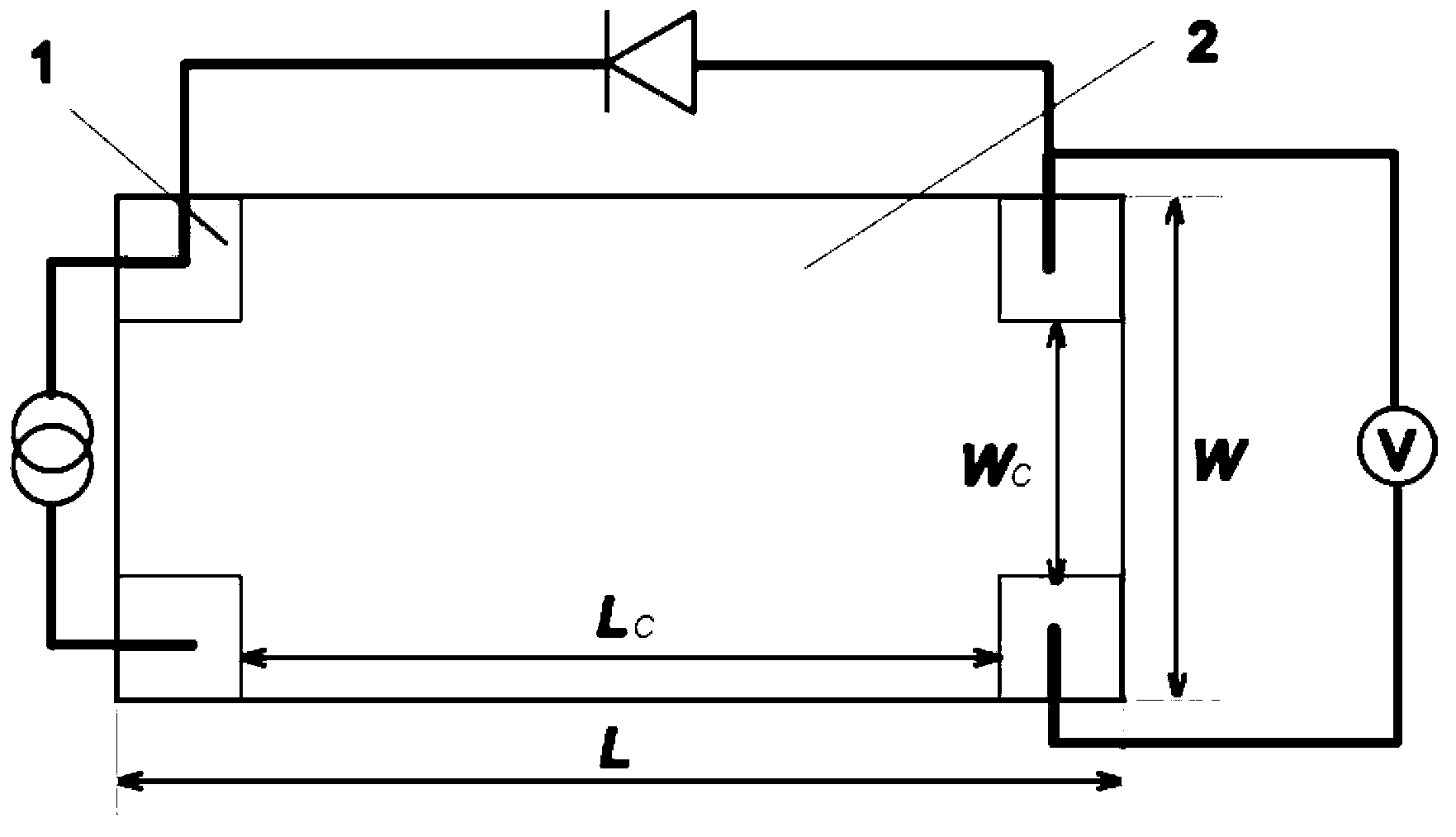

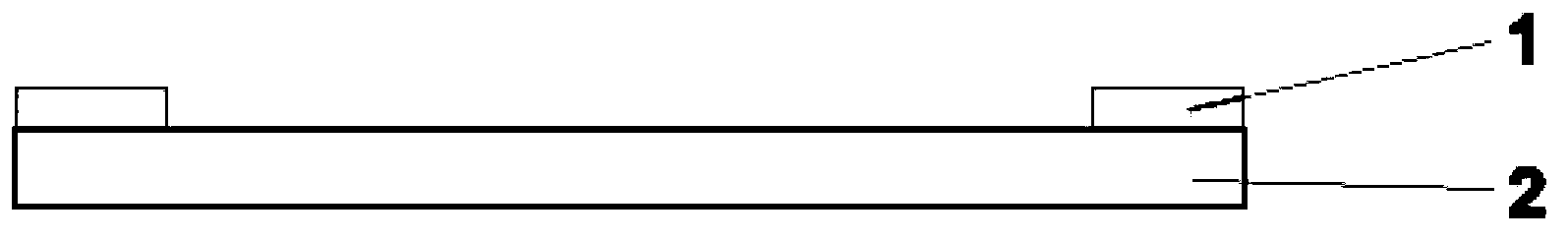

[0029] Set the resistivity to 10 7 The Ω?cm semi-insulating GaAs (100) substrate was rinsed with alcohol or acetone, and cut into a rectangle with a length of L = 7.0 mm and a width of W = 2.3 mm. High-purity soft metal In (purity>99.9%) is used to press the metal electrodes on the four corners of the rectangular GaAs substrate. The size of the metal electrode is 1.0 mm along the length direction of the GaAs substrate and 0.9 mm along the width direction of the GaAs substrate. Therefore L C = 5.0 mm, W C = 0.5 mm. So far, a gallium arsenide-based geometric giant magnetoresistive device has been fabricated.

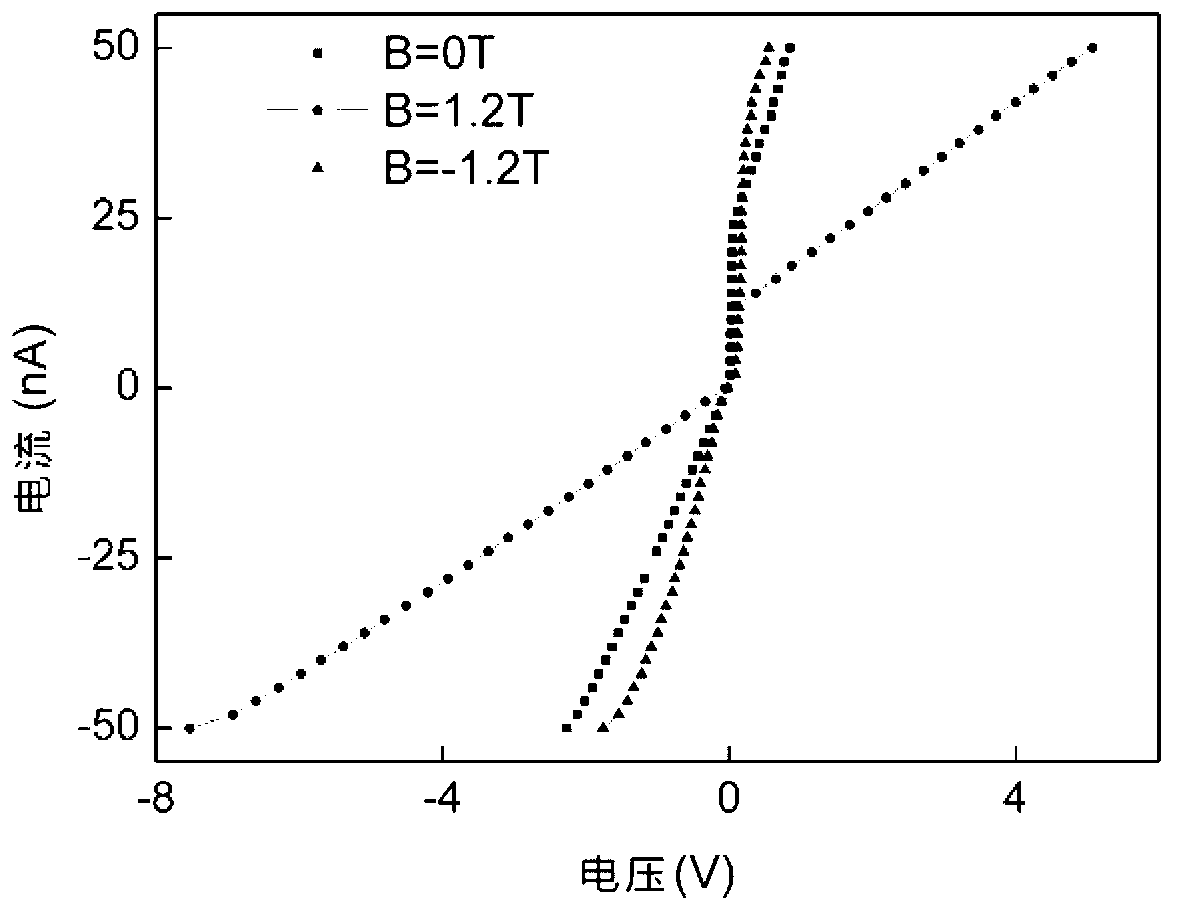

[0030] When using the four-electrode method to measure the magnetoresistance performance of the device, the current source connected to two adjacent metal electrodes in the width direction provides current, and the voltmeter connected to the other two adjacent metal electrodes in the width direction tests the voltage. A diode is connected between a pair of adjacent...

Embodiment 2

[0034] Set the resistivity to 10 7 The Ω?cm semi-insulating GaAs (100) substrate was rinsed with alcohol or acetone, and cut into a rectangle with a length of L = 4.3 mm and a width of W = 2.3 mm. The electrodes are pressed on the four corners of the rectangular GaAs substrate with high-purity soft metal In (purity>99.9%). The size of the electrodes is 1.15 mm along the length direction of the GaAs substrate and 0.9 mm along the width direction of the GaAs substrate. Therefore L C = 2.0 mm, W C = 0.5 mm. So far, a gallium arsenide-based geometric giant magnetoresistive device has been fabricated.

[0035] The test method, conditions and equipment of the prepared gallium arsenide-based geometric giant magnetoresistor are the same as those in Example 1.

[0036] When the current is 24 nA, its magnetoresistance can reach 700% under the condition of 1.2 T magnetic field.

Embodiment 3

[0038] Set the resistivity to 10 7 The Ω?cm semi-insulating GaAs (100) substrate was rinsed with alcohol or acetone, and cut into a rectangle with a length of L = 4.3 mm and a width of W = 2.3 mm. The electrodes are pressed on the four corners of the rectangular GaAs substrate with high-purity soft metal In (purity>99.9%). The size of the electrodes is 1.15 mm along the length direction of the GaAs substrate and 0.9 mm along the width direction of the GaAs substrate. Therefore L C = 2.0 mm, W C = 0.5 mm. So far, a gallium arsenide-based geometric giant magnetoresistive device has been fabricated.

[0039] The prepared gallium arsenide-based geometric giant magnetoresistor uses a Zener diode with a reverse breakdown voltage of 15V, and its test method, conditions and equipment are the same as those in Example 1.

[0040] When the current is 24 nA, its magnetoresistance can reach 1000% under the condition of 1.2 T magnetic field.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com