Storage monitoring management system and method

A technology of monitoring management and storage tanks, applied in the field of automation management and control, can solve the problems of less automatic control loops, high labor intensity of operators, environmental pollution, etc., and achieve the effect of improving the degree of automation, eliminating hidden dangers of accidents, and increasing monitoring means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

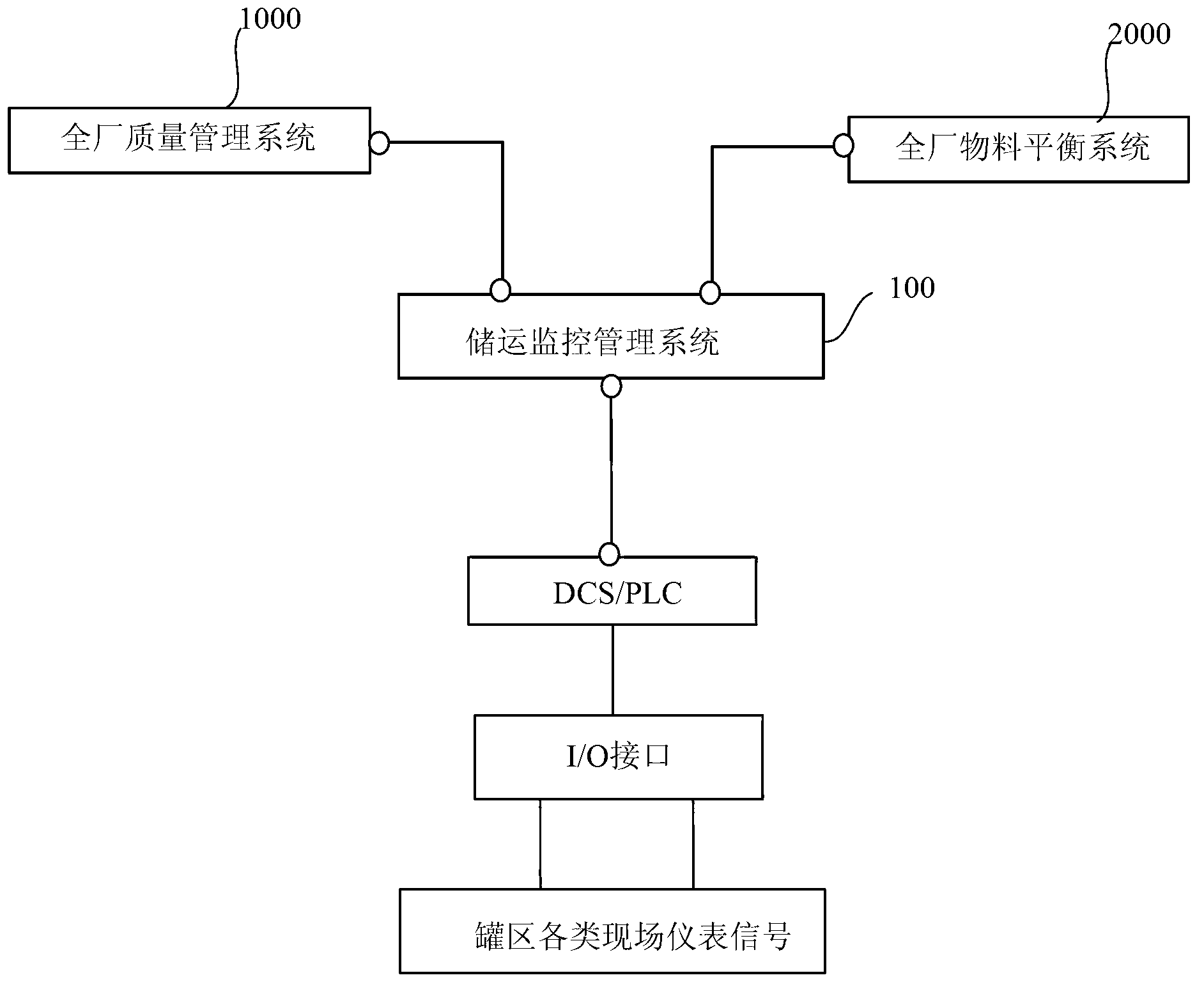

[0024] figure 1 A block diagram of a storage and transportation monitoring and management system according to an embodiment of the present invention is shown. refer to figure 1 As shown, the hardware platform of the storage and transportation monitoring and management system (OMS) 100 in this embodiment may be a distributed control system (DCS) or a PLC system, and the control system may include a process control station 101 , a data acquisition station 102 , and an operation station 103. An engineer station 104, an auxiliary console 105, a network device 106, and a control network 107 with a redundant structure. The DCS system or PLC system is based on an "open" system architecture, that is, the system itself should have the ability to integrate and exchange information with other types of system equipment and platforms through industry standard communications, platforms and protocols. In one embodiment, the communication protocol support may include HART (Highway Addressab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com