Involute gear waviness sample plate

A technology of involute gears and involutes, applied in machine gear/transmission mechanism testing, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

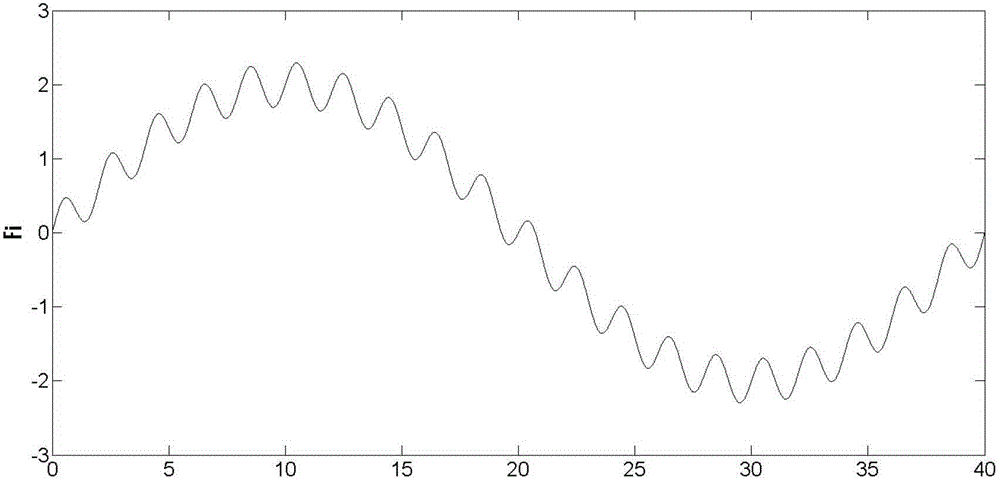

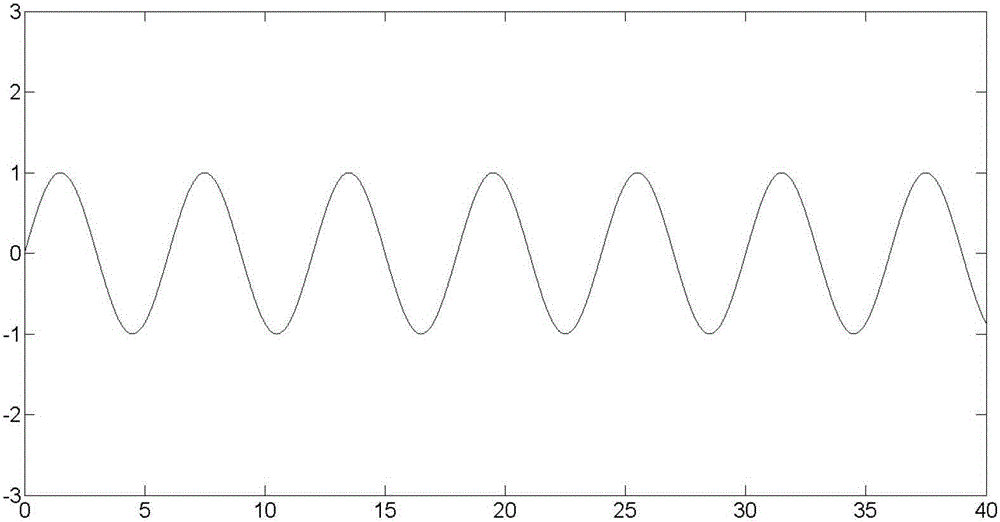

[0045] Attached below Figure 6 , the present invention is further described:

[0046] Gear parameters: module: 5.5mm, number of teeth: 14, pressure angle 20°, helix angle 0°, addendum coefficient 0.8, superimposed first harmonic wavelength is 2.7061mm, amplitude is 5um, superimposed second harmonic wavelength It is 1.3531mm and the amplitude is 5um. The first harmonic and the second harmonic are simultaneously superimposed on all tooth surfaces, and the initial phase of the superimposed harmonic is 0°. According to the formula of the mathematical model of the involute gear waviness template, the first and second harmonics designed above are superimposed on the corresponding tooth surface, and the coordinate values of each tooth surface are calculated, and the involute is completed using the machine tool Gear waviness model processing. The schematic diagram of the mathematical model of the involute gear waviness template is as follows Figure 8 shown.

[0047] The speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com