Metal aluminate covering film agent, a manufacturing method thereof and metal aluminate covering film

A technology of metal aluminum salt and its production method, which is applied in the coating process of metal materials, etc., can solve the problems of difficult painting or coloring, time-consuming and labor-intensive processing, and high processing cost, and achieve the effects of water saving, convenient use, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

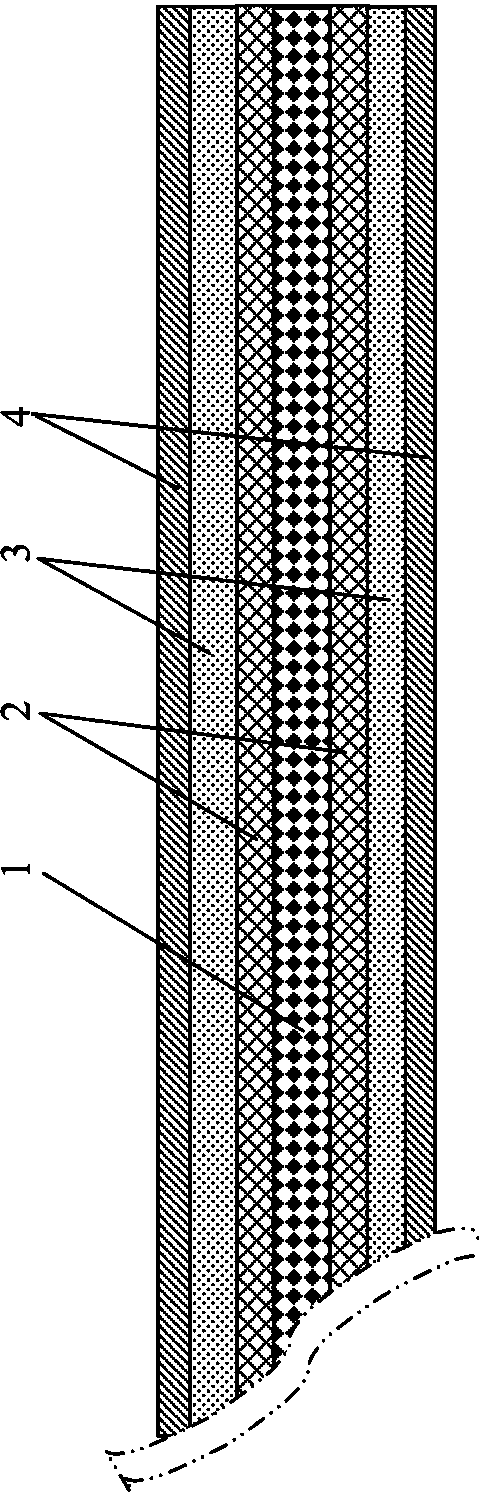

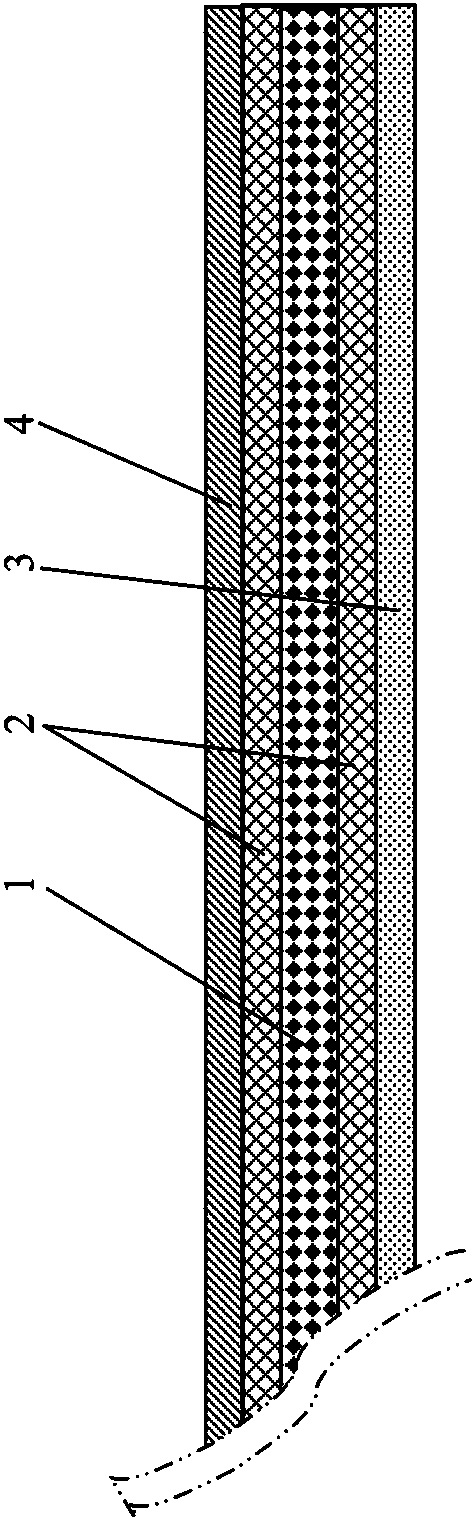

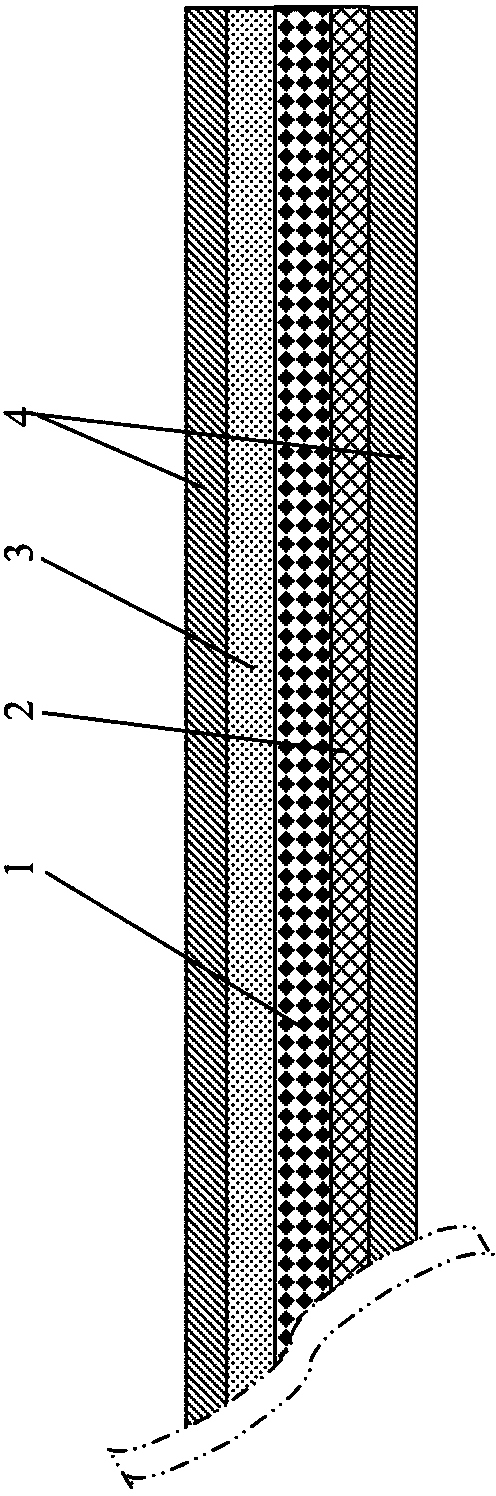

Image

Examples

Embodiment 1

[0045] Embodiment 1: Adopted on the surface of the locomotive cast iron engine case.

[0046] In this embodiment, the components and weight percentages of the metal aluminum salt coating agent of the present invention are: edible phosphoric acid 10-12%, aluminum oxide 4.5-5%, zinc oxide 1-2%, phosphatidic acid 1-1.5%, Manganese 1-2%, the balance of water.

[0047] The specific production method steps are as follows:

[0048] 1) First prepare the ingredients according to the ratio, and divide the remaining water into three equal parts;

[0049] 2) Prepare a low-pressure reaction kettle for the container, make the ambient temperature above 30-40°C, and pour the prepared edible phosphoric acid into it;

[0050] 3) Add alumina, then add a portion of water, stir until completely dissolved;

[0051] 4) Add zinc oxide, add a portion of water, and stir until completely dissolved;

[0052] 5) Add manganese, add a portion of water, and stir until completely dissolved;

[0053] 6) A...

Embodiment 2

[0056] Embodiment 2: Applied on the surface of the cast steel body of the locomotive.

[0057] In this embodiment, the components and percentages by weight of the metal aluminum salt coating agent of the present invention are: 18-20% of edible phosphoric acid, 5% of aluminum oxide, 2-4% of zinc oxide, 1-1.5% of phosphatidic acid, 1% of manganese -2%, water balance.

[0058] The specific production method steps are as in Example 1, the difference is that in step 7: use roller coating, brush coating or wiping coating, and keep the ambient temperature at 5°C-20°C to dry naturally, which forms a 25-28 micron film layer on the surface of the cast steel body .

[0059] The locomotive is assembled with this kind of cast steel body, which has good anti-corrosion effect.

Embodiment 3

[0060] Embodiment 3: Applied on the surface of profiles such as Q plates and angle steels.

[0061] In this embodiment, the components and weight percentages of the metal aluminum salt coating agent of the present invention are: edible phosphoric acid 20-25%, aluminum oxide 5-8%, nickel oxide 1-1.8%, zinc oxide 2-3%, phosphorus Esteric acid 1-1.5%, manganese 1-2%, water balance.

[0062] The specific production method steps are as follows:

[0063] 1) First prepare the ingredients according to the ratio, and divide the remaining water into four equal parts;

[0064] 2) Prepare a container so that the ambient temperature reaches above 30-40°C, and pour the prepared edible phosphoric acid into it;

[0065] 3) Add alumina, then add a portion of water, stir until completely dissolved;

[0066] 4) Add nickel oxide, add a portion of water, and stir until completely dissolved;

[0067] 5) Add zinc oxide directly, add a portion of water, and stir until completely dissolved;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com