A method for the manufacture of a foamed polymer body

A polymer and fluid technology, applied in the field of preparing foamed polymers, can solve the problem of not being able to cross-link and foam at the same time, and achieve the effects of eliminating the flushing process, small maintenance and high operational safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

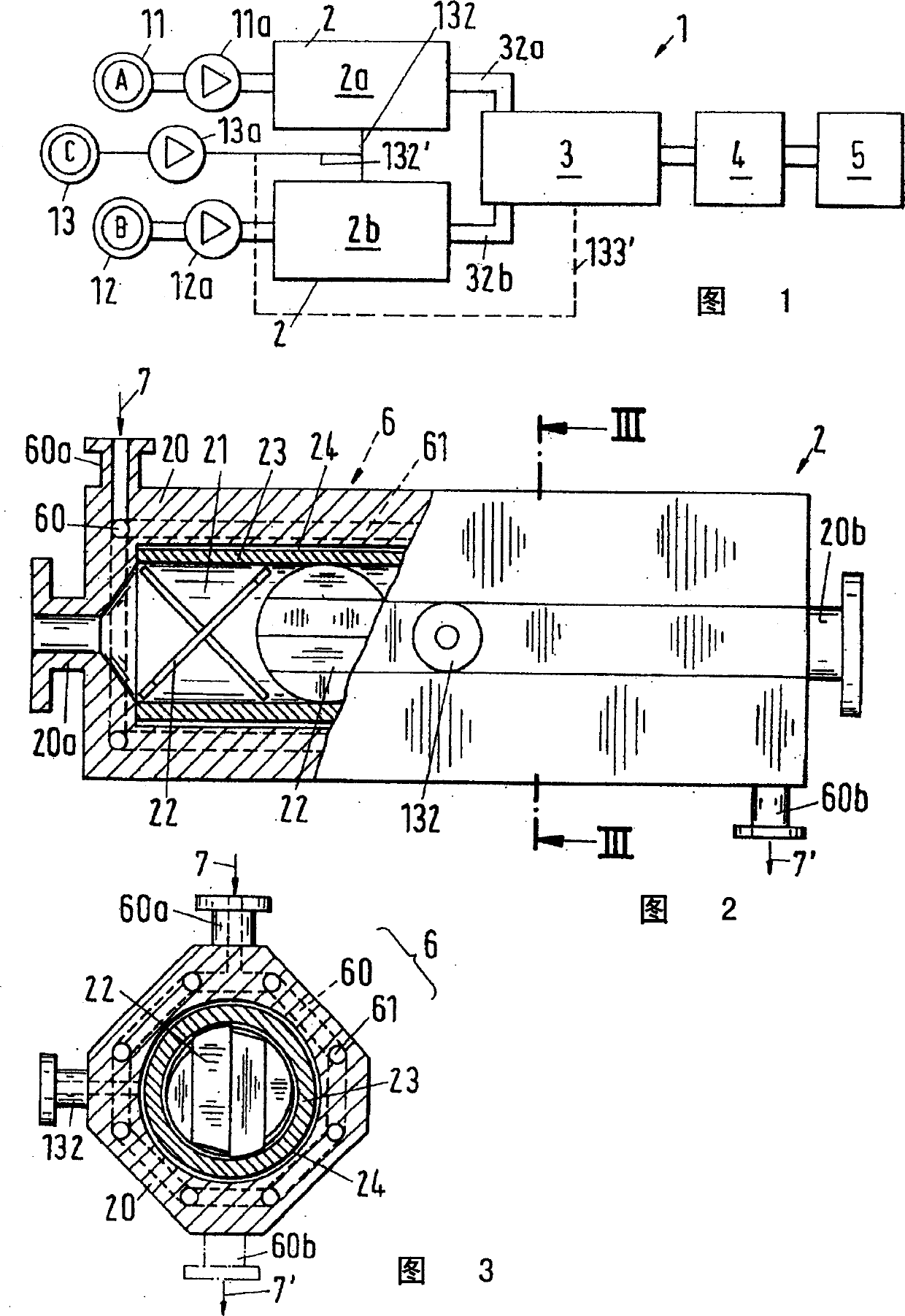

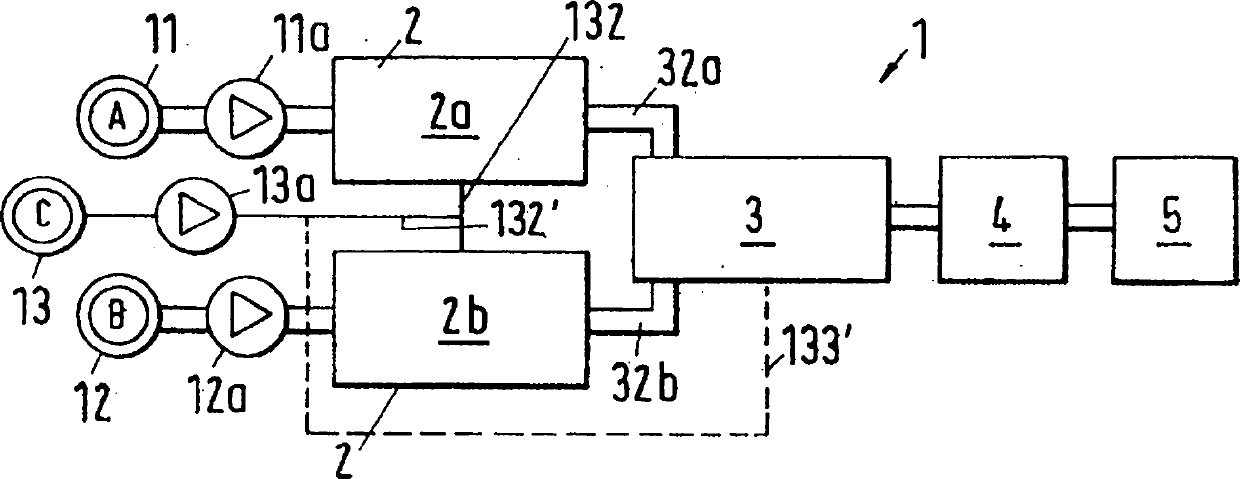

[0018] Apparatus 1 that can implement the method according to the invention, such as figure 1 shown in the block diagram. Storage tanks 11 and 12 for molding composition components A and B are connected to impregnation devices 2a and 2b, respectively, via pumps 11a, 11b. (It is also possible to arrange only one impregnation device). Embodiment 2 for the impregnation apparatus 2 a , 2 b is described with reference to FIGS. 2 and 3 . Polymers or polymer moldings foamed according to the invention can be produced by means of an injection molding machine, devices 2 a , 2 b and mixing device 3 . Foaming and crosslinking reactions proceed simultaneously in the molding tool 5 . Variations of the method using extrusion tools are also possible.

[0019] Before processing the molding composition, the molding composition is present in the form of two separately held components A and B. They all include partial reagents for carrying out the crosslinking reaction; they differ due to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com