Adjusting and arranging mechanism for enabling leaves to face same direction in tea leaf printing production line

A production line and printing technology, which is applied in the field of adjusting and arranging mechanisms, can solve problems such as time-consuming and laborious, and achieve the effects of improving uniformity, improving efficiency, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

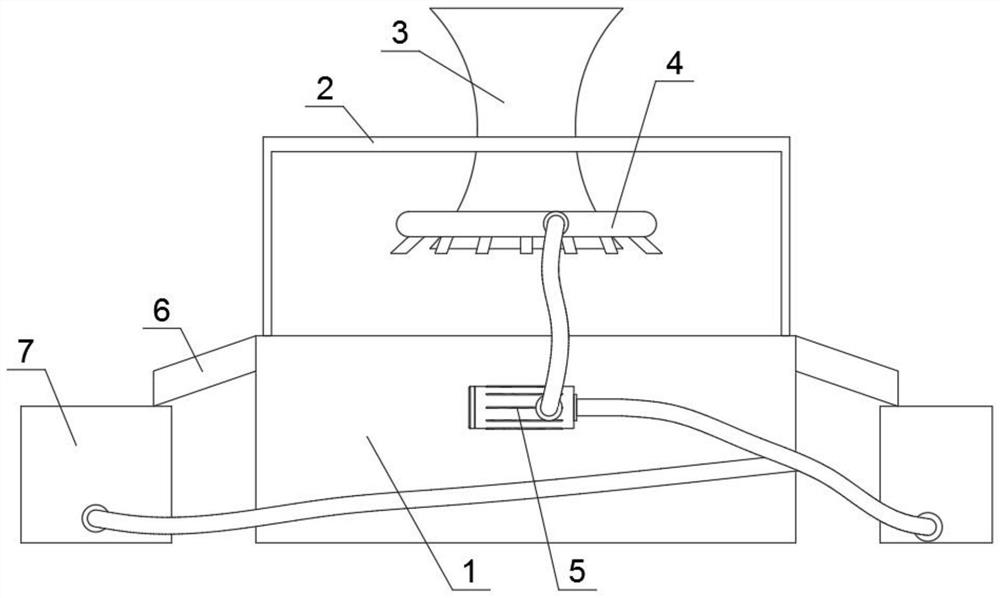

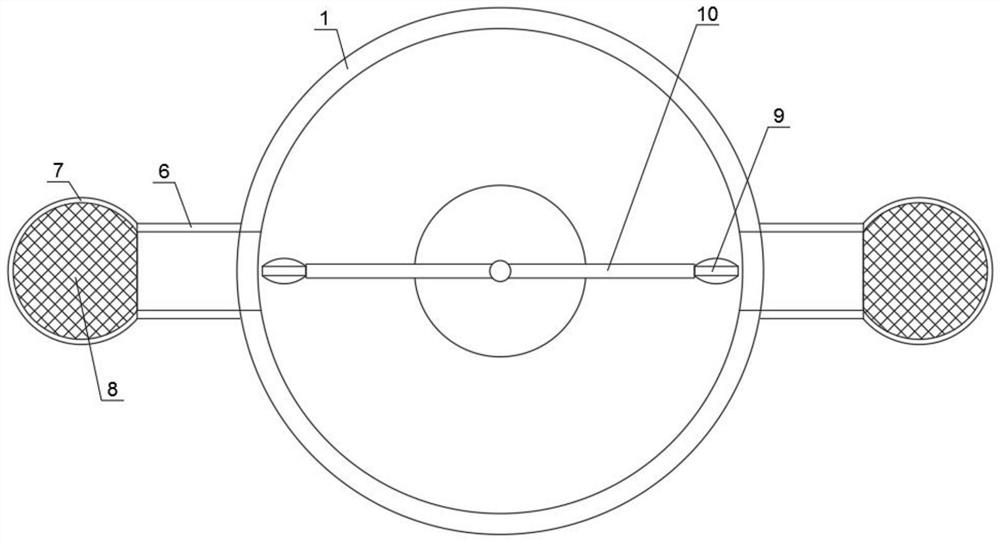

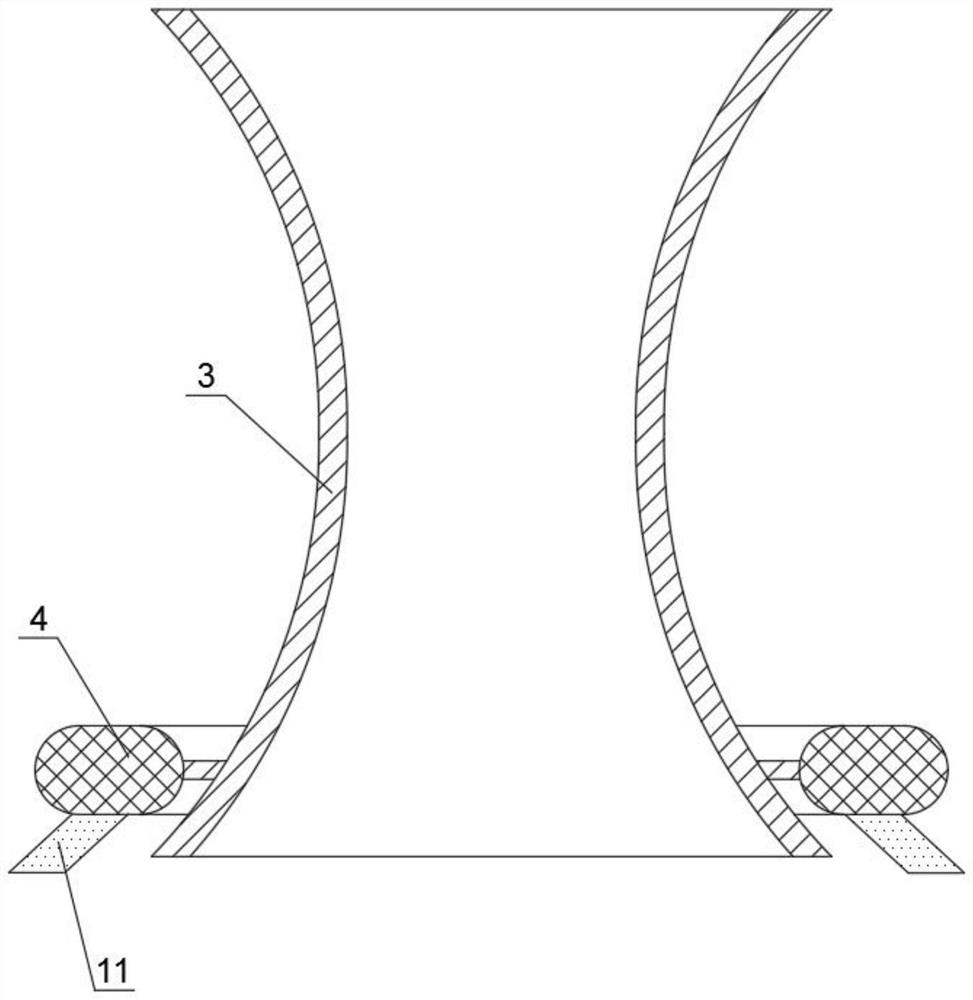

[0031] Examples, see Figure 1-5 , the present invention provides a technical solution: a mechanism for adjusting and arranging leaves in the same direction in a tea printing production line, including an adjusting box 1, the top of the adjusting box 1 is fixedly connected with a mounting frame 2, and a feeding cylinder is installed inside the mounting frame 2 3. A ring pipe 4 is installed at the bottom of the outer end surface of the feeding cylinder 3. The outer end surface of the ring pipe 4 is annular and equidistantly installed with multiple groups of nozzles 11. Both sides of the adjustment box 1 are provided with a retrieving box 7, and the adjustment box 1 The side near the retrieving box 7 is fixedly connected with the lower hopper 6 which is inclined, and the bottom of the lower hopper 6 near the side of the reclaiming box 7 is overlapped with the top of the reclaiming box 7, and the external installation of the adjustment box 1 There is a water pump 5, the water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com