Method for treating cupric oxide or zinc oxide ores by adopting agitation ammonia leaching and infiltration basin ammonia leaching in combination

A percolation tank and copper oxide technology, applied in the direction of improving process efficiency, can solve the problems of difficult sealing of wet grinding equipment and spiral grading equipment, deterioration of industrial hygiene conditions in production workshops, and increased production costs, so as to improve industrial hygiene Conditions, saving grinding energy consumption, and reducing the effect of liquid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

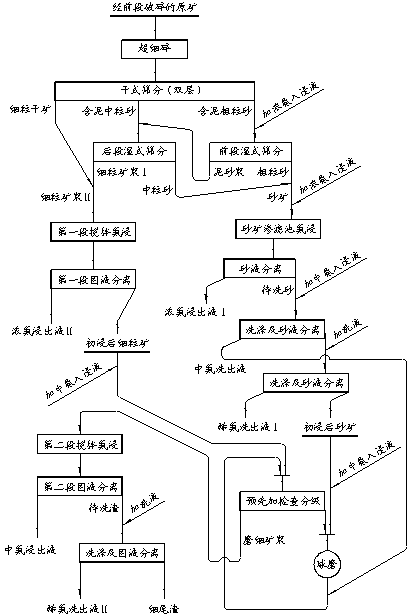

Method used

Image

Examples

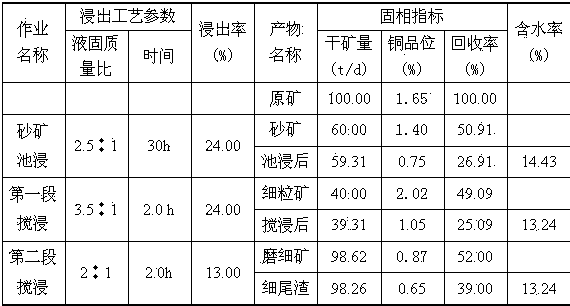

Embodiment 1

[0040] Refractory copper oxide ore with high alkaline gangue content: copper content 1.65%, free copper oxide distribution rate 70.30%, combined copper distribution rate 28.48%, copper sulfide distribution rate 1.22%, CaO: 28.12%, MgO : 2.80%, Fe: 7.97%, Al 2 o 3 : 0.90%, SiO 2 : 9.28% (both are mass percentages, test results after drying, the same below).

[0041] After the above raw ore is crushed beforehand, it is processed according to the following process steps:

[0042] (1) Ultra-fine crushing: Ultra-fine crushing of the raw ore to a particle size of 3mm, and the mass percentage of moisture is controlled to 4%;

[0043] (2) Combined screening: For the materials treated in step (1), first perform dry screening (the sieve aperture of the upper sieve is 1.0mm, and the sieve aperture of the lower sieve is 0.4mm) to separate the upper layer of mud Coarse-grained sand, medium-grained sand with mud in the middle layer and fine-grained dry ore in the lower layer; then add c...

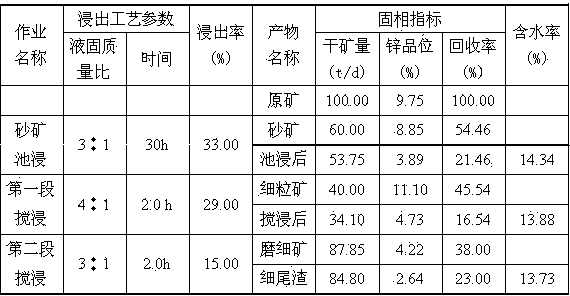

Embodiment 2

[0056] Refractory zinc oxide ore with high alkaline gangue content: 9.75% zinc, 82.75% zinc in carbonate and sulfate form, 14.87% zinc in silicate form, 14.87% zinc in sulfide form Rate 2.38%, Pb: 1.86%, CaO: 15.62%, Fe: l3.73%, MgO: 1.84%, Al 2 o 3 : 2.90%, Si0 2 : 13.76%.

[0057] After the above raw ore is crushed beforehand, it is processed according to the following process steps:

[0058] (1) Ultra-fine crushing: Ultra-fine crushing of the raw ore to a particle size of 3mm, and the mass percentage of moisture is controlled to 4%;

[0059] (2) Combined screening: For the materials treated in step (1), first perform dry screening (the sieve aperture of the upper sieve is 1.0mm, and the sieve aperture of the lower sieve is 0.4mm) to separate the upper layer of mud Coarse-grained sand, medium-grained sand with mud in the middle layer and fine-grained dry ore in the lower layer; then add concentrated ammonia into the immersion solution to the coarse-grained sand with mud,...

Embodiment 3

[0071] Refractory copper oxide ore with high alkaline gangue content: copper content 0.78%, free copper oxide distribution rate 79.82%, copper binding rate 8.27%, copper sulfide distribution rate 11.91%, CaO: 16.42%, MgO: 7.74%, Al 2 o 3 : 6.87%, SiO 2 : 18.37%, Fe 2 o 3 : 5.33%.

[0072] After the above raw ore is crushed beforehand, it is processed according to the following process steps:

[0073] (1) Ultra-fine crushing: Ultra-fine crushing of the raw ore to a particle size of 3mm, and the mass percentage of moisture is controlled at 5%;

[0074] (2) Combined screening: For the materials treated in step (1), first perform dry screening (the sieve aperture of the upper sieve is 1.2mm, and the sieve aperture of the lower sieve is 0.5mm) to separate the upper sieve with mud Coarse-grained sand, medium-grained sand with mud in the middle layer and fine-grained dry ore in the lower layer; then add concentrated ammonia into the immersion solution to the coarse-grained sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com