Preparation method of stable fluorescent carbon

A fluorescent and stable technology, applied in the field of material chemistry, to achieve high yield, simple method and environmental friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of stable fluorescent carbon of the present invention is:

[0026] 1) Prepare glutinous rice liqueur and set aside;

[0027] 2) Mix glutinous rice wine with double distilled water;

[0028] 3) Put the above mixed system into the reactor and react in the hydrothermal reactor;

[0029] 4) Collect the supernatant after the reaction, which is a stable aqueous solution of fluorescent carbon nanoparticles.

[0030] The mass ratio of the glutinous rice liqueur to twice distilled water is 11-20%.

[0031] The above-mentioned hydrothermal reaction temperature is 140-180°C.

[0032] The above reaction time is 16 to 24 hours.

Embodiment 1

[0034] (1) Preparation of glutinous rice liqueur: Soak 500 grams of glutinous rice in clean water for 1 hour, change the water and wash it, remove it; put clean water in the pot, put the glutinous rice in, put it on the fire, and cook it with high heat. Cook until the glutinous rice is five mature, take it out, wash it with cold water twice, drain the water, steam it in a cage, pour it into a pot, and set aside; roll 250 grams of distiller's koji into noodles, put them in the glutinous rice and stir well, Slap the top flat, and use a small rolling pin to punch a hole with a diameter of 2 cm in the middle to make the air circulate; cover it with a cloth in summer and a quilt in winter, keep the temperature at about 30 degrees, and let it ferment. ;Standby; Mix 3g glutinous rice liqueur with 27 mL double distilled water, stir for 5 minutes;

[0035] (2) Transfer the above mixed system to the reactor, and react at 140°C for 20 hours;

[0036] (3) The supernatant is collected to ...

Embodiment 2

[0039] (1) Preparation of glutinous rice liqueur: prepare by the method of Example 1, and set aside; mix 5 g of glutinous rice liqueur with 25 mL of double-distilled water, and stir for 5 minutes;

[0040] (2) Transfer the above mixed system to the reactor, and react at 160°C for 24 hours;

[0041] (3) The supernatant is collected to obtain an aqueous solution of fluorescent carbon nanoparticles.

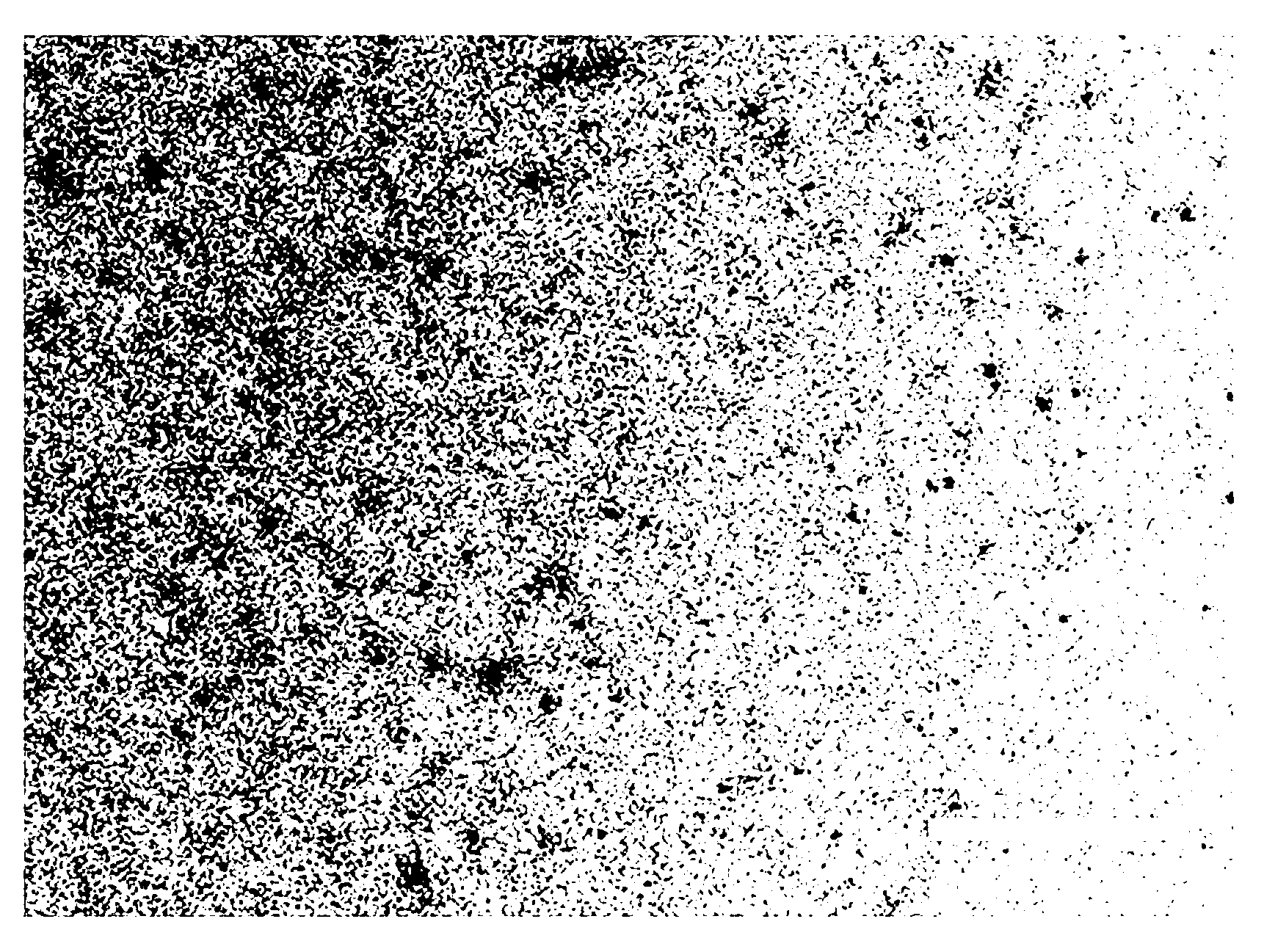

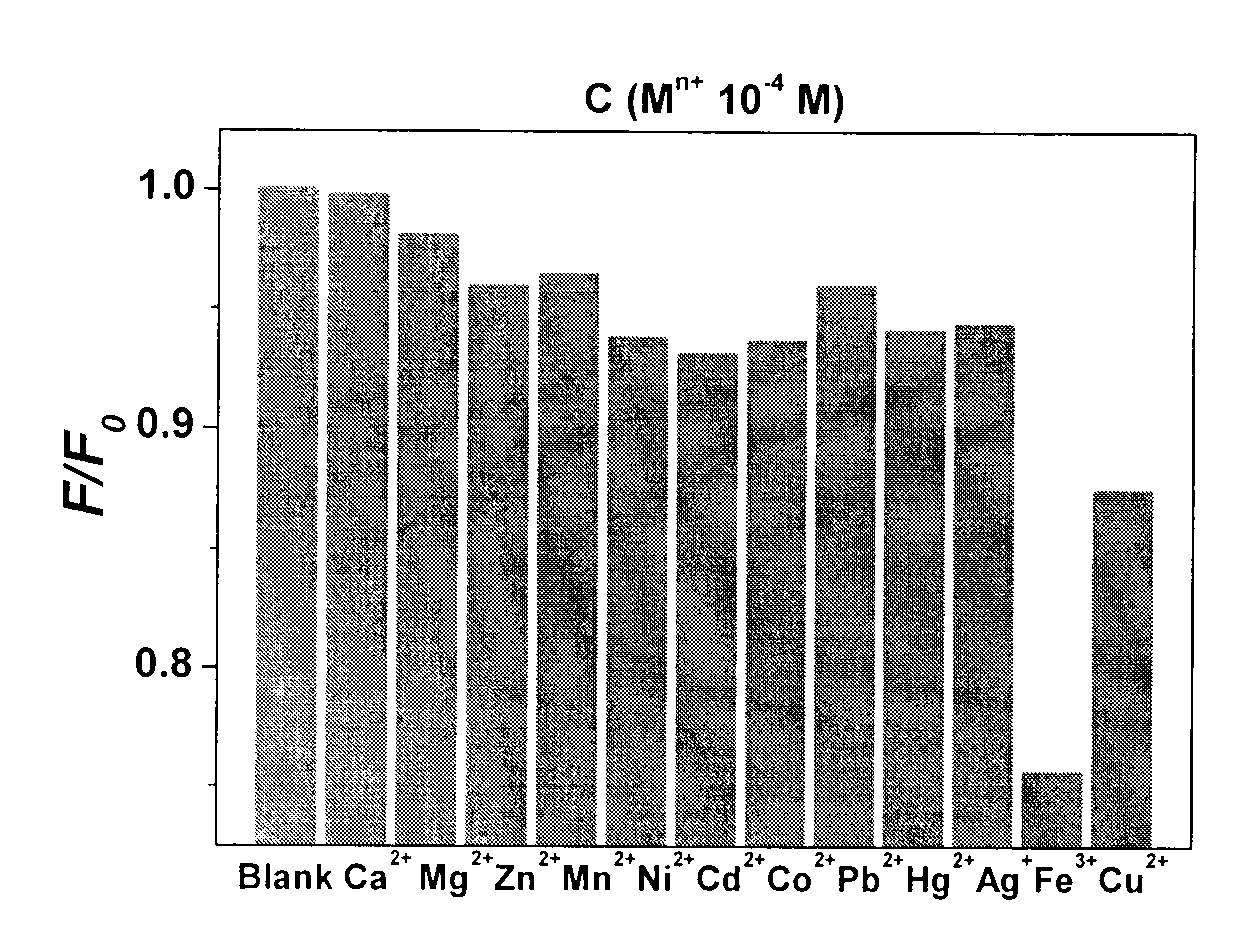

[0042] The transmission electron micrograph of the obtained fluorescent carbon nanoparticles is shown in figure 1 Photos of fluorescent carbon nanoparticles under , UV and fluorescent light irradiation are shown in figure 2 , and the aqueous solution of fluorescent carbon nanoparticles on Fe 3+ For the experimental results of sensing, see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com