Proportional bi-component condensed type organic silicon sealant stable in storage and preparation method thereof

A storage-stable, equal-proportion technology, applied in the direction of chemical instruments and methods, non-polymer adhesive additives, adhesives, etc., can solve the problems of non-curing, increased costs, restrictions, etc., and achieve excellent physical and mechanical properties and good adhesion effect, the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

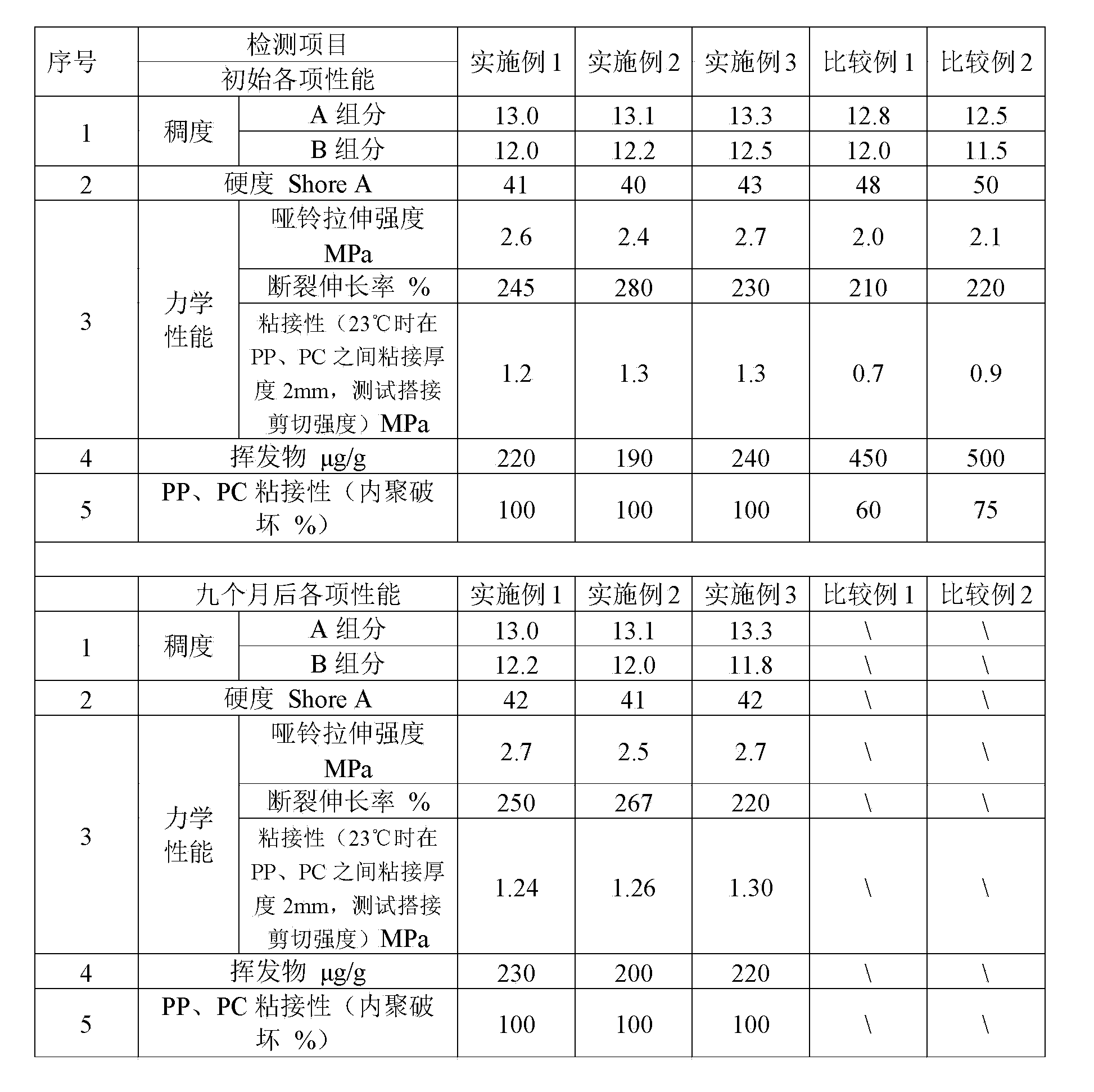

Examples

Embodiment 1

[0041] A component

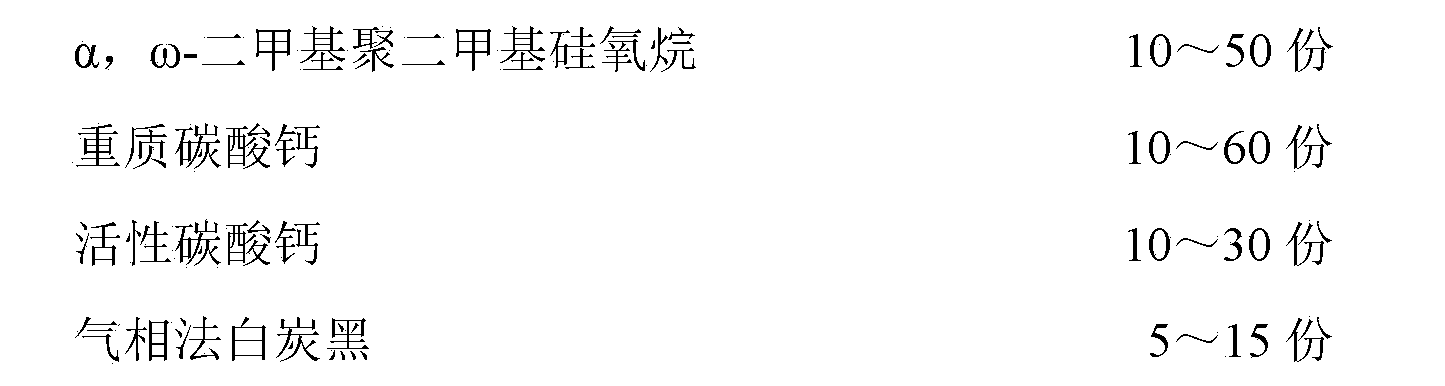

[0042] Add 100 parts by mass of α, ω-dihydroxy polydimethylsiloxane and 60 parts by mass of active calcium carbonate into a high-speed dispersing mixer for blending, keep the vacuum at 0.08MPa, and the speed is 600r / min, stir for 120min, and mix in a vacuum Continue vacuum stirring at 0.08MPa for 10 minutes to obtain component A.

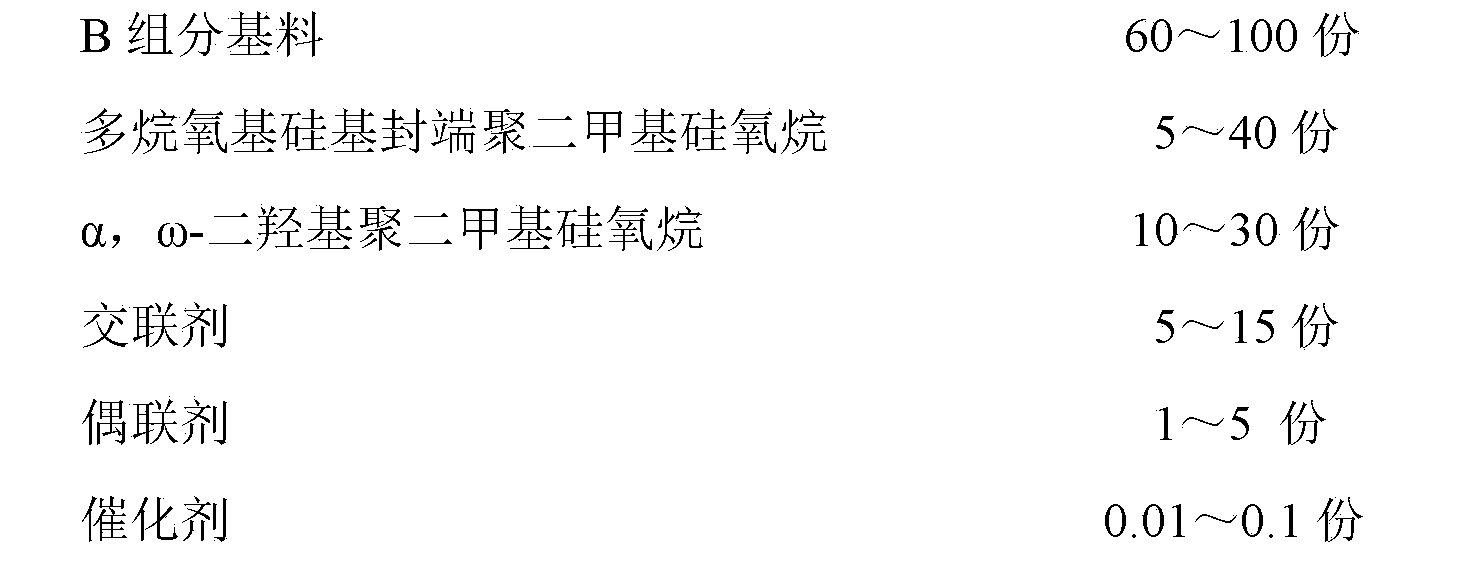

[0043] B component

[0044] 30 parts by mass of α, ω-dimethyl polydimethylsiloxane, 15 parts by mass of specific surface 400m 3 / g fumed white carbon black, 40 parts by mass of heavy calcium carbonate, and 20 parts by mass of active calcium carbonate are added to a vacuum kneader, and dehydrated and blended for 60 minutes at a temperature of 100°C and a vacuum of 0.08MPa to obtain a component B base material.

[0045] Combine 60 parts by mass of the B-component base material obtained above with 40 parts by mass of polyalkoxysilyl-terminated polydimethylsiloxane, 10 parts by mass of methyltrimethoxysilane, and 5 parts by mass ...

Embodiment 2

[0048] A component

[0049] Add 80 parts by mass of α, ω-dihydroxypolydimethylsiloxane and 40 parts by mass of active calcium carbonate into a high-speed dispersion mixer for blending, keep a vacuum of 0.099MPa, and a rotation speed of 800r / min. Continue vacuuming and stirring for 30 min under MPa to obtain component A.

[0050] B component

[0051] 10 parts by mass of α, ω-dimethyl polydimethylsiloxane, 5 parts by mass of specific surface 150m 2 / g fumed white carbon black, 60 parts by mass of heavy calcium carbonate, and 10 parts by mass of active calcium carbonate are added to a vacuum kneader, and dehydrated and blended for 120 minutes at a temperature of 150°C and a vacuum of 0.099MPa to obtain the B component base material.

[0052] Combine 80 parts by mass of the B-component base material obtained above with 20 parts by mass of polyalkoxysilyl-terminated polydimethylsiloxane, 5 parts by mass of methyltriethoxysilane, and 5 parts by mass of ethyl orthosilicate Esters, ...

Embodiment 3

[0055] A component

[0056] Add 50 parts by mass of α, ω-dihydroxypolydimethylsiloxane and 20 parts by mass of active calcium carbonate into a high-speed dispersing mixer for blending, keep a vacuum of 0.08MPa, and a rotating speed of 600r / min. Continue vacuuming and stirring for 20 min under MPa to obtain component A.

[0057] B component

[0058] 50 parts by mass α, ω-dimethyl polydimethylsiloxane, 10 parts by mass specific surface 200m 2 / g fumed white carbon black, 20 parts by mass of heavy calcium carbonate, and 30 parts by mass of active calcium carbonate were added to a vacuum kneader at a temperature of 120°C and a vacuum of 0.08MPa, and were dehydrated and blended for 120 minutes to obtain component B base material.

[0059] Mix 100 parts by mass of the B-component base material obtained above with 5 parts by mass of polyalkoxysilyl-terminated polydimethylsiloxane, 15 parts by mass of vinyltrimethoxysilane, and 3 parts by mass of γ-aminopropyl Triethoxysilane, 2 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com