Method for preparing dopamine-modified hyaluronic acid micelle

A technology of hyaluronic acid and dopamine, applied in the field of polymer materials and natural macromolecules, to achieve the effect of easy reaction, excellent biocompatibility and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

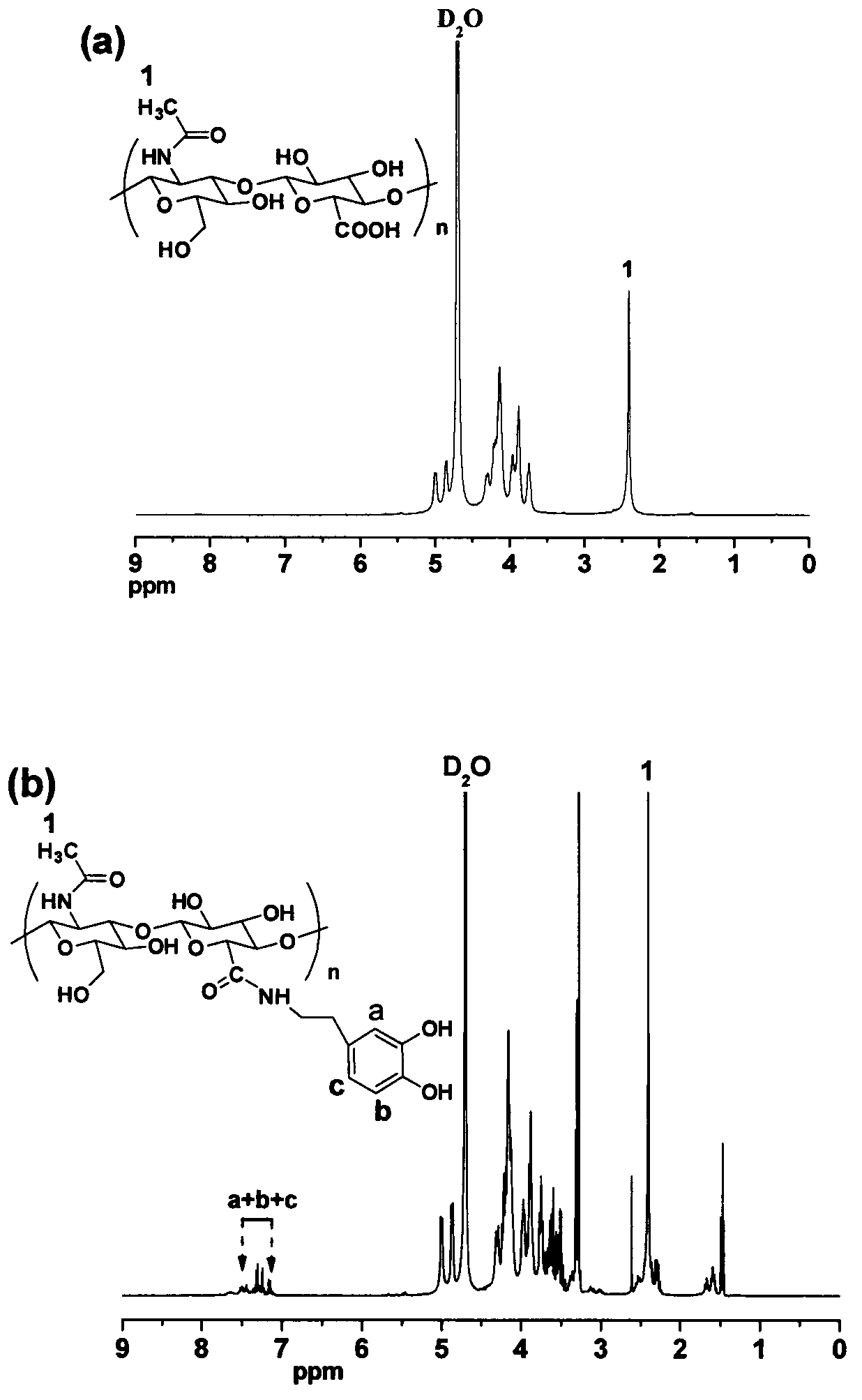

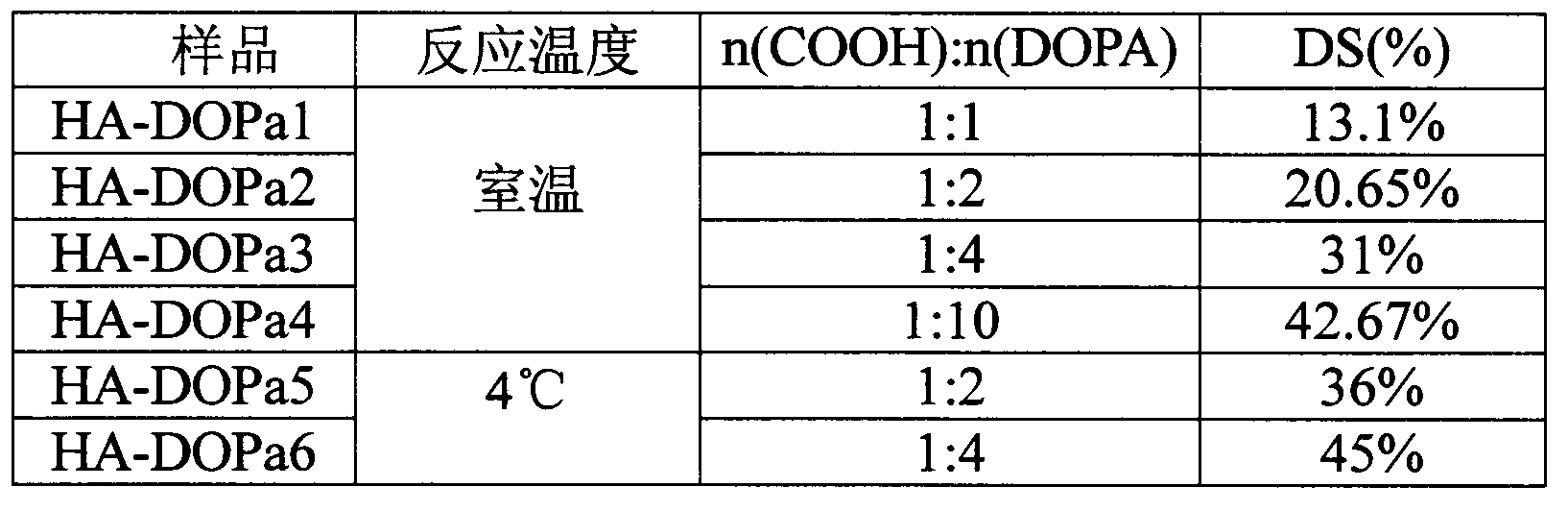

[0028] (1) Preparation of hyaluronic acid graft

[0029] Weigh 2g with a molecular weight of 3.1×10 5 Da hyaluronic acid (HA), put into a 250mL single-necked flask, add 80mL deionized water, stir and dissolve at room temperature for 1h after vacuumizing. After complete dissolution, adjust the pH of the solution to 5.5, add 1.91g of EDC, 1.15g of NHS and 1.35g of HOBt, and stir for 1h to activate the carboxyl group. In addition, 1.8 g of dopamine hydrochloride (DOPA) was weighed, put into a flask containing HA, vacuumized for 15 min, and reacted at room temperature for 24 h. The reaction solution was dialyzed in deionized water for 4 to 6 days to remove the catalyst and unreacted monomers, and an ultraviolet spectrometer was used to track the absorption peak of dopamine in the dialysate at around 280 nm until the absorbance was 0, then freeze-dried to obtain the grafted product HA-DOPA.

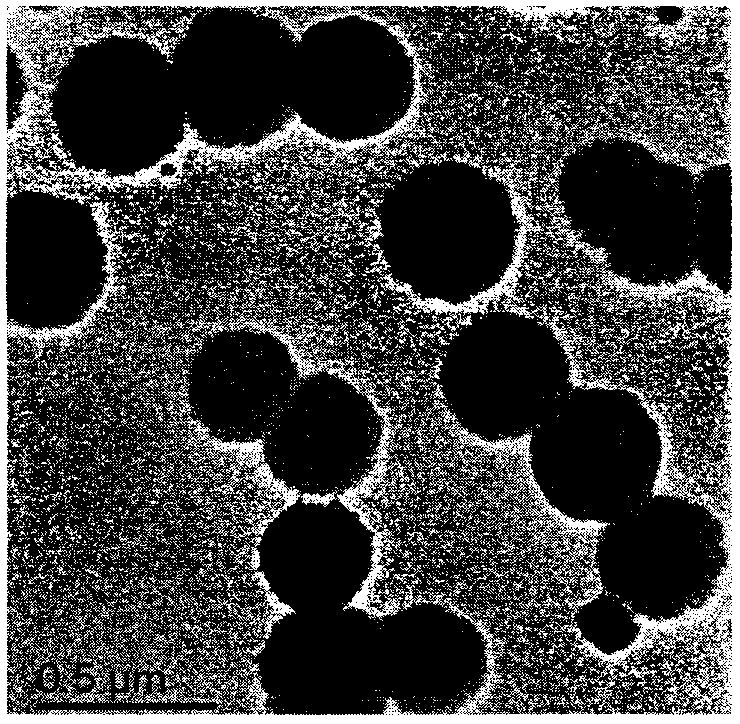

[0030] (2) Preparation of hyaluronic acid micelles

[0031] Weigh 0.5g HA-DOPA, dissolv...

Embodiment 2

[0035] (1) The preparation of the hyaluronic acid graft was the same as in Example 1.

[0036] (2) The preparation of hyaluronic acid micelles is the same as in Example 1.

[0037] (3) Preparation of emulsion

[0038] Adjust a series of 3 mL of the above micellar aqueous solution with different pH, add an equal volume of white oil, and mix and homogenize at 8000 rpm for 2 minutes to obtain a series of emulsions. The emulsification effect of the emulsion can be well controlled by the acidity and alkalinity of the system.

Embodiment 3

[0040] (1) Preparation of hyaluronic acid graft

[0041] Weigh 2g of hyaluronic acid (HA), put it into a 250mL single-necked flask, add 80mL of deionized water, stir and dissolve at room temperature for 1h after vacuuming. After complete dissolution, adjust the pH of the solution to 5.5, add 1.91g of EDC, 1.15g of NHS and 1.35g of HOBt, and stir for 1h to activate the carboxyl group. In addition, 9 g of dopamine hydrochloride (DOPA) was weighed, put into a flask containing HA, vacuumized for 15 min, and reacted at room temperature for 24 h. The reaction solution was dialyzed in deionized water for 4 to 6 days to remove the catalyst and unreacted monomers, and the absorption peak of dopamine in the dialysate at around 280nm was tracked with an ultraviolet spectrometer until the absorbance was 0, then freeze-dried to obtain the grafted product HA-DOPA .

[0042] (2) The preparation of hyaluronic acid micelles is the same as in Example 1.

[0043] (3) Preparation of emulsion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com