Polyurethane with electrochromism performance and preparation method thereof

An electrochromic, polyurethane technology, applied in the preparation of organic compounds, the preparation of carbamate derivatives, and color-changing fluorescent materials, etc., can solve the problems of difficulty in measuring electrochromic properties, easy shedding, etc., and achieve good electrochemical redox reversibility. The effect of high stability, high cycle life and high sensitivity to color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

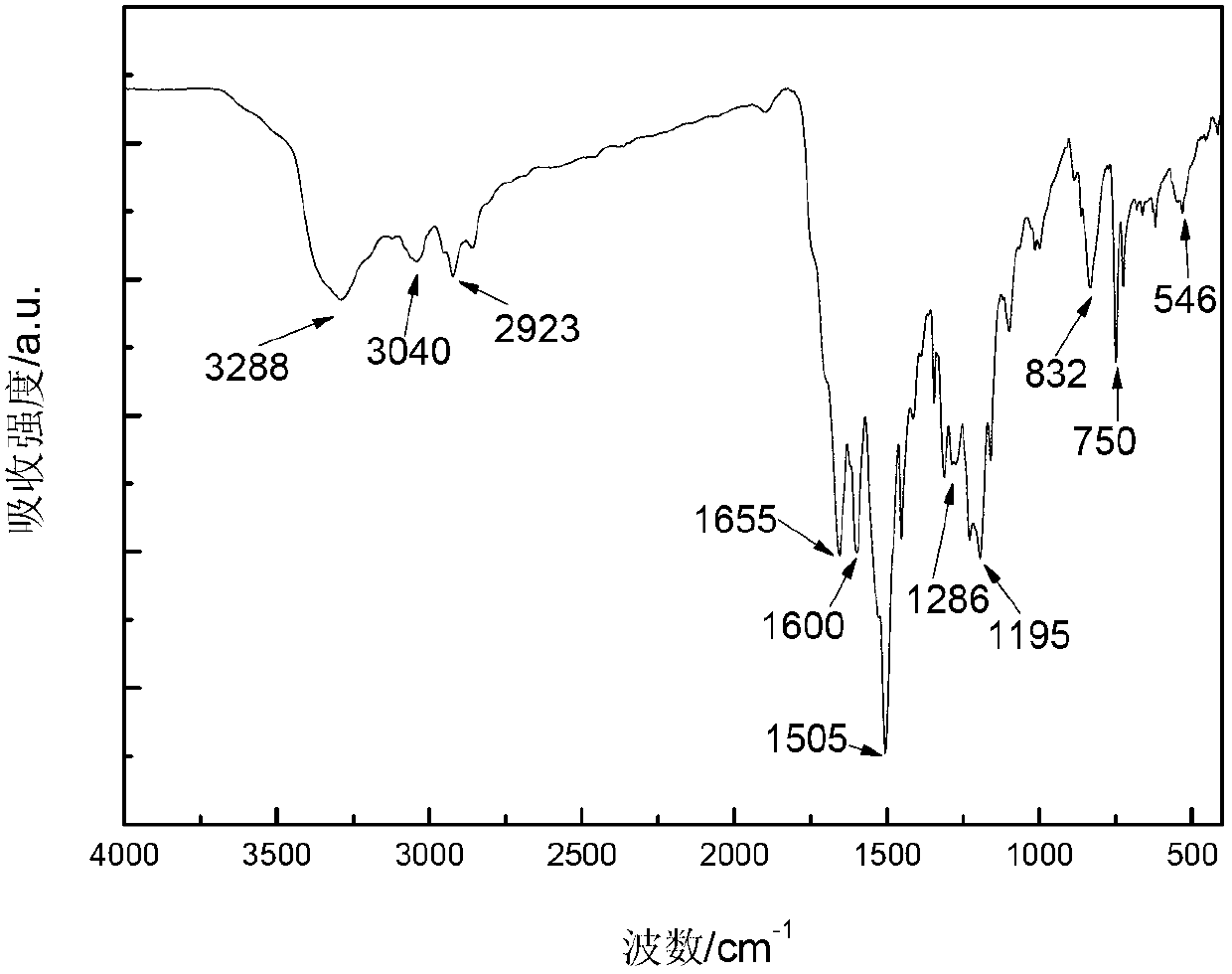

Method used

Image

Examples

specific Embodiment approach 2

[0033] Specific embodiment two: the preparation method of a kind of polyurethane with electrochromic performance of the present embodiment is carried out according to the following steps:

[0034] 1. Synthesis of monomers

[0035] a, diaminotriphenylamine derivatives and p-Hydroxybenzaldehyde are mixed uniformly in a molar ratio of 1: 2 to 3 to obtain a mixture; b, the mixture obtained in step a and the solvent are in a mass volume ratio of 0.8 to 2.1g : 100mL ratio to mix evenly to obtain a mixed solution, then under the condition of nitrogen protection, raise the temperature of the mixed solution to 120°C-140°C, stir at a speed of 20-50rpm, when the solvent in the mixed solution evaporates to the original volume of the mixed solution When the volume is 1 / 4, stop stirring and collect the remaining 1 / 4 volume of liquid; c. Put the remaining 1 / 4 volume of liquid collected in step b into distilled water, let it stand for 6-12 hours, and then put it in a vacuum with a degree of 0...

specific Embodiment approach 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the diaminotriphenylamine derivative described in step 1 is 4,4′-diamino-4″-N-carbazolyltriphenylamine, N, N-bis(4-aminophenyl)-N',N'-diphenyl-1,4-phenylenediamine, N'-(4-aminophenyl)-N'-(4-ethoxy) Phenyl-1,4-phenylenediamine, N,N'-bis(β-naphthyl)-N,N'-bis(4-aniline)-p-phenylenediamine, N'-(4-aminophenyl) -N'-phenyl-1,4-phenylenediamine, N',N'-diphenyl-N,N'-di(4-aniline)-p-phenylenediamine, N',N'-diphenyl -N, N'-bis(4-phenylamine) biphenylenediamine or N,N'-bis(α-naphthyl)-N,N'-bis(4-phenylamine)biphenylenediamine.Others and step 2 same.

specific Embodiment approach 4

[0040] Embodiment 4: The difference between this embodiment and Embodiments 2 to 3 is that the molar ratio of the diaminotriphenylamine derivative and p-hydroxybenzaldehyde described in step 1 is 1:2-3. Others are the same as steps two to three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com