Method for quickly separating and preparing high-purity deoxyrhapontin and rhapontin

A technology for deoxygenating rhubarb and rhubarb, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve problems such as hidden dangers of resin raw material safety, low product purity, complicated operation, etc., and achieve Conducive to quality control, high purity, high preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

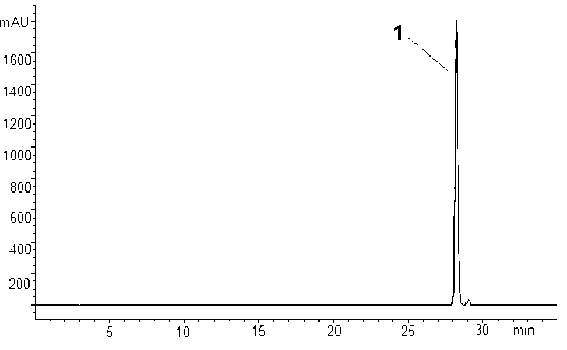

Image

Examples

Embodiment 1

[0034] Example 1 A method for rapidly separating and preparing high-purity deoxyrhein and erinacein, comprising the following steps:

[0035] (1) Weigh 50 g of the dried root of the cultivated rhubarb, cut it into 5 mm slices, and obtain the raw material for extraction.

[0036](2) Add 250mL of ethanol solution with a mass concentration of 80% to the extraction raw materials, and place it in a HH-4 constant temperature water bath produced by Guohua Electric Appliance Co., Ltd., heat and reflux at 40°C for 4 hours, and the extraction times are 2 times. The combined extracts were collected to obtain a crude extract; the crude extract was concentrated and dried under reduced pressure at 50°C and vacuumed to a negative pressure of 0.01 MPa using an R-114 rotary evaporator produced by Buchi BUCHI Laboratory Technology Co., Ltd., Switzerland. Constant weight yielded 16 g of extract.

[0037] (3) Mix the four solvents of methanol, water, n-butanol and chloroform according to the v...

Embodiment 2

[0043] Example 2 A method for rapidly separating and preparing high-purity deoxyrhein and erinacein, comprising the following steps:

[0044] (1) Weigh 50 g of the dried root of rhubarb cultivated in Hetao, and use a high-speed universal pulverizer produced by Beijing Kewei Yongxing Instrument Co., Ltd. to pulverize it into 80-mesh powder to obtain the raw material for extraction.

[0045] (2) Add 750mL of ethanol solution with a mass concentration of 40% to the extracted raw materials, and place it in a HYR automatic decoction machine produced by Tianjin Huayanyuan Machinery Co., Ltd., heat and reflux at 90°C for 3 hours, and the number of extractions is 3 times , collect and combine the extracts to obtain the crude extract; the crude extract is concentrated and dried under reduced pressure at 30°C and vacuumed to a negative pressure of 0.1MPa using the R-114 rotary evaporator produced by Buchi BUCHI Laboratory Technology Co., Ltd. To constant weight, 21 g of extract were o...

Embodiment 3

[0052] Example 3 A method for rapidly separating and preparing high-purity deoxyrhein and erinacein, comprising the following steps:

[0053] (1) Weigh 50 g of the dried root of wild rhubarb rhubarb, and use a high-speed universal pulverizer produced by Beijing Kewei Yongxing Instrument Co., Ltd. to pulverize it into a 10-mesh powder to obtain the raw material for extraction.

[0054] (2) Add 550mL of ethanol solution with a mass concentration of 50% to the extracted raw materials, and place it in a HYR automatic decoction machine produced by Tianjin Huayanyuan Machinery Co., Ltd., heat and reflux at 70°C for 0.5 hours, and the number of extractions is 4 times , collect and combine the extracts to obtain the crude extract; the crude extract is concentrated and dried under reduced pressure at 45°C and vacuumed to a negative pressure of 0.05MPa using the R-114 rotary evaporator produced by Buchi BUCHI Laboratory Technology Co., Ltd. To constant weight, 20 g of extract was obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com