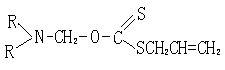

Dialkyl amido amine methyl butylxanthate compound and synthetic method thereof

A technology of dialkylaminoaminomethyl xanthate acrylate and propylene xanthate, which is applied in the field of aminomethylxanthate acrylate compounds and their synthesis, and can solve the problem of dialkylaminomethyl xanthate. The stability of the drug is not strong, so as to achieve the effect of good beneficiation and collection performance, good collection performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

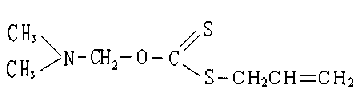

[0045] Embodiment 1: O-dimethylaminomethyl-S-propenyl xanthate and its synthetic method

[0046] In the general formula, R is ethyl C 2 h 5 - The product of O-dimethylaminomethyl-S-propenyl xanthate

[0047] The synthesis process:

[0048] (1) For the synthesis of dimethylaminomethanol, take 136g of 33% dimethylamine aqueous solution and put it into a reaction bottle, start stirring, add 75g of 40% formaldehyde aqueous solution dropwise, drop it for about 0.5h, react at room temperature for 2h, and then Add 2.5g of fine-grained sodium chloride salt, stir and dissolve to carry out salting-out, cool down to below 20°C and let it stand for stratification, separate the water in the lower layer, and the light yellow product in the upper layer is dimethylaminomethanol, a total of 68g is collected. The reaction formula is:

[0049]

[0050] (2) Synthesis of dimethylaminomethyl xanthate: Take 38g of carbon disulfide and 42.5g of dimethylaminomethanol into the reaction flask,...

Embodiment 2

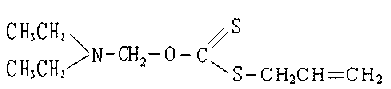

[0054] Embodiment 2: O-diethylaminomethyl-S-propenyl xanthate and its synthetic method

[0055] In the general formula, R is ethyl C 2 h 5 - The product of O-diethylaminomethyl-S-propenyl xanthate

[0056] The synthesis process:

[0057] (1) Synthesis of diethylaminomethanol, put 73g of diethylamine into the reaction bottle, start stirring, add 75g of 40% formaldehyde solution dropwise, drop it for about 0.5h, react at room temperature for 1h, then heat up to 45~ 65°C, continue to react for 2.5h, then add 1.5g of fine-grained sodium chloride salt, stir and dissolve for salting out, cool down to below 20°C and let it stand for stratification, separate the water in the lower layer, and the light yellow product in the upper layer is diethylamino Methanol, a total of 117 g was collected. The reaction formula is:

[0058]

[0059] (2) Synthesis of diethylaminomethyl xanthate: Take 76g of carbon disulfide and 117g of diethylaminomethanol into the reaction flask, start stir...

Embodiment 3

[0063] Embodiment 3: O-di-n-butylaminomethyl-S-propenyl xanthate and its synthesis method

[0064] In the general formula, R is n-butyl n-C 4 h 9 -The synthetic process of the product O-di-n-butylaminomethyl-S-propenyl xanthate:

[0065]

[0066] (1) Synthesis of di-n-butylaminomethanol, put 129g of di-n-butylamine into the reaction bottle, start stirring, add 75g of 40% formaldehyde solution dropwise, drop it for about 0.5h, react at room temperature for 1h, then heat up to 45~65°C, continue to react for 2.5h, then add 1.5g of fine-grained sodium chloride salt, stir and dissolve for salting out, cool down to below 20°C and let it stand for stratification, separate the water in the lower layer, and the light yellow product in the upper layer is dinormal Butylaminocarbinol, 173 g collected. The reaction formula is:

[0067]

[0068] (2) Synthesis of di-n-butylaminomethyl xanthate: Take 38g of carbon disulfide and 85g of di-n-butylaminomethanol into the reaction flask,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com