Method for preparing 2-ethyl hexanoic acid by catalytically oxidizing 2-ethylhexanal by molybdovanadophosphoric acid

A technology of phosphomolybdic vanadium heteropolyacid and ethylhexanal, which is applied in the preparation of carboxylates, chemical instruments and methods, preparation of organic compounds, etc., to achieve the effects of high yield, reduced production cost and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

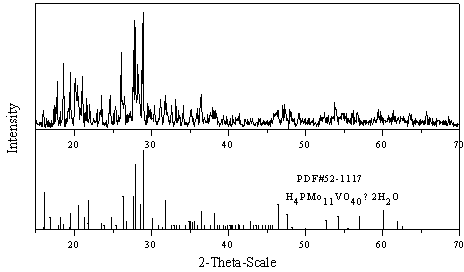

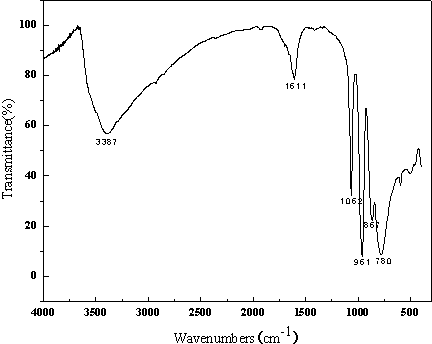

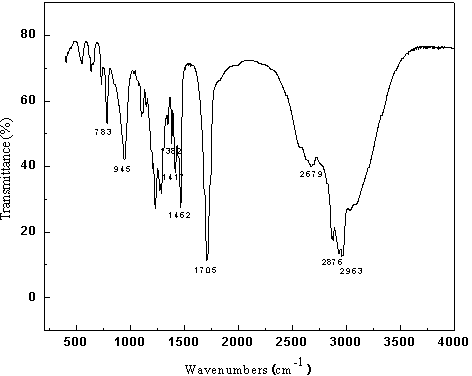

Image

Examples

Embodiment approach 1

[0023] Embodiment 1: Weigh 20.00 g of sodium molybdate, 6.00 g of disodium hydrogen phosphate, and 1.85 g of sodium metavanadate, and dissolve them in deionized water respectively. Put the disodium hydrogen phosphate solution in a constant temperature water bath at 80°C, then slowly add the sodium molybdate solution into the disodium hydrogen phosphate solution, then slowly add concentrated sulfuric acid to the mixed solution for acidification until the solution becomes light yellow. Add the sodium metavanadate solution into the mixed solution acidified with sulfuric acid, and continue to add concentrated sulfuric acid dropwise under vigorous stirring until the solution becomes a transparent orange-red solution. Heating and stirring were stopped, and the mixed solution of the three solutions was cooled to room temperature. Finally, the mixed solution was transferred to a separatory funnel, and a little ether was added. After fully shaking, the layers were allowed to stand and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com