Low-melting point glass powder and manufacturing method thereof

A technology of low-melting point glass and manufacturing method, which is applied in the field of low-melting point glass powder and its manufacturing, can solve the problems of small range, limited range of use of lead-free barium borate low-melting point glass, high use temperature, etc., and achieve good wettability As well as fluidity, good chemical stability, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

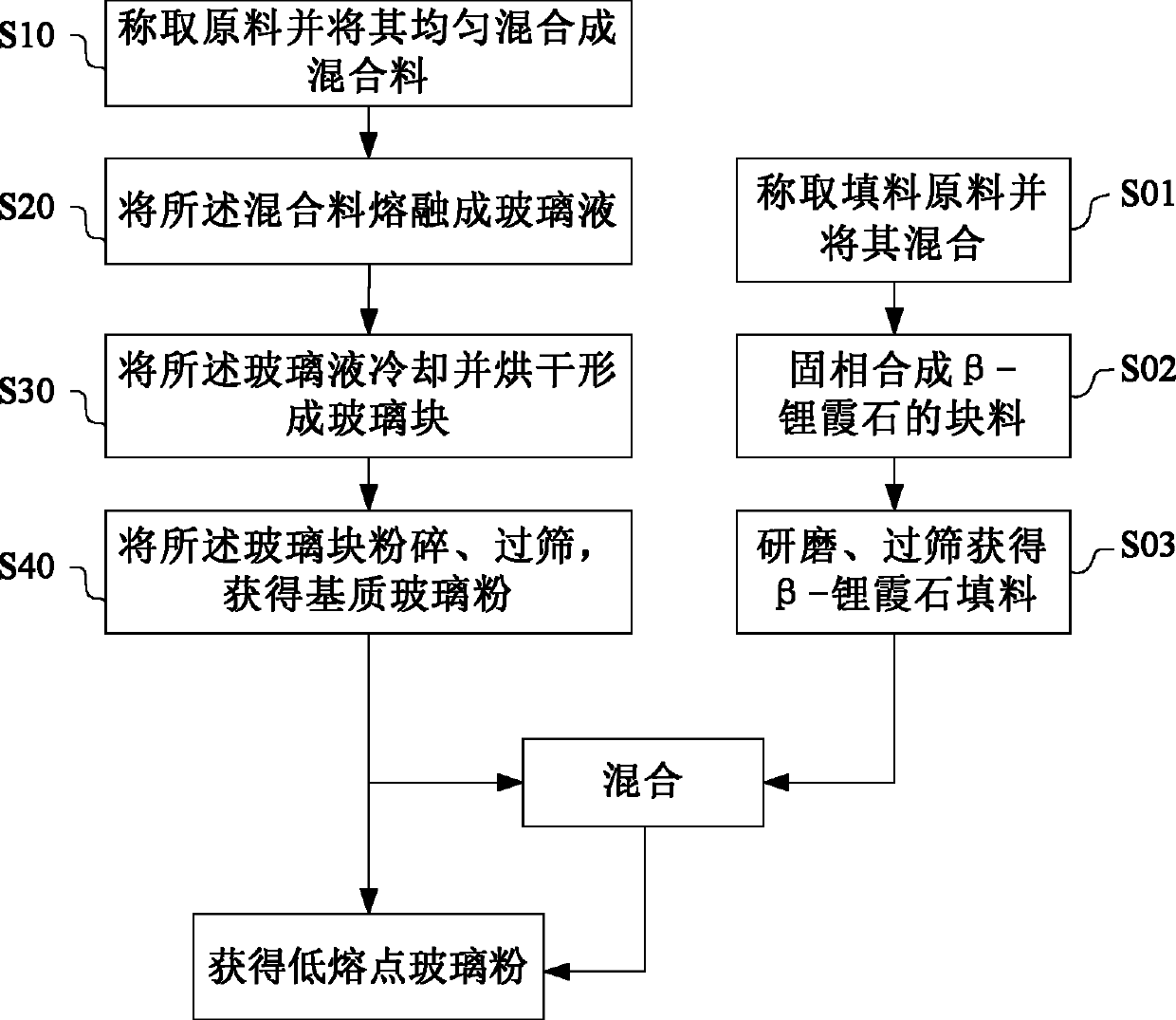

[0033] In order to enable those skilled in the art to better understand the technical solution of the present invention, the low-melting glass powder provided by the present invention and its manufacturing method will be described in detail below with reference to the accompanying drawings.

[0034] The low-melting glass powder that present embodiment provides is Bi 2 o 3 -B 2 o 3 - ZnO-BaO quaternary system glass powder, and does not contain lead element, this low melting point glass powder can be directly used for sealing of VFD, PDP, CRT, or for sealing between glass, ceramics and metals.

[0035] The low-melting glass powder of the present embodiment comprises (expressed in % by weight): bismuth oxide (Bi 2 o 3 )20~55%, boron oxide (B 2 o 3 ) 10-30%, zinc oxide (ZnO) 5-15%, barium oxide (BaO) 15-40%, copper oxide (CuO) 0.5-5%, magnesium oxide (MgO) 0.5-2%, and halide 0.2- 5%.

[0036]Wherein, the halide is one or a mixture of two or more of tin fluoride, zinc fluor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sealing temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com