Method for preparing 0.84 nm kaolinite hydrate by hydrazine hydrate-kaolinite intercalation complex

A technology of intercalation complex and hydrated kaolinite, applied in silicon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problem that the content of hydrated kaolinite needs to be increased, the preparation period of hydrated kaolinite is long, and the preparation conditions are harsh. and other problems, to achieve the effect of simple heat treatment process, easy production and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] a. Weigh 1 g of kaolinite, measure 20 ml of hydrazine hydrate, put them into a closed glass container and mix them, and stir on a magnetic stirrer for 24 hours at room temperature to obtain hydrazine hydrate-kaolinite intercalation complex and hydrazine hydrate mixture.

[0026] b. Centrifuge the mixture, remove the upper liquid, add absolute ethanol, mix well, centrifuge again, repeat once, wash away excess hydrazine hydrate, and obtain hydrazine hydrate-kaolinite intercalation complex;

[0027] c. Treat the hydrazine hydrate-kaolinite intercalation complex at 40° C. for 8 hours.

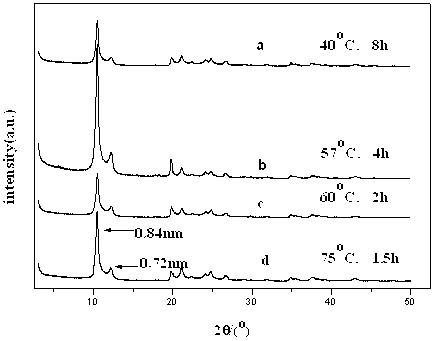

[0028] The hydrated kaolinite X-ray diffraction prepared by the above steps figure 1 (a), the interlayer spacing is expanded from 0.72nm of the original stone to 0.84nm, and the obtained hydrated kaolinite content is 87%. Such as figure 1 (a) shown.

Embodiment 2

[0030] a. Weigh 0.5g of kaolinite, measure 20ml of hydrazine hydrate, mix in a closed glass container, and stir on a magnetic stirrer at room temperature for 36h to obtain hydrazine hydrate-kaolinite intercalation complex and hydrazine hydrate Hydrazine mixture.

[0031] b. Centrifuge the mixture, remove the upper liquid, add absolute ethanol, mix well, centrifuge again, repeat once, wash away excess hydrazine hydrate, and obtain hydrazine hydrate-kaolinite intercalation complex;

[0032] c. Treat the hydrazine hydrate-kaolinite intercalation complex at 57° C. for 4 hours.

[0033] The hydrated kaolinite X-ray diffraction prepared by the above steps figure 1 (b), the interlayer spacing is expanded from 0.72nm of the original stone to 0.84nm, and the obtained hydrated kaolinite content is 87%. Such as figure 1 (b) shown.

Embodiment 3

[0035] a. Weigh 1.5g of kaolinite, measure 20ml of hydrazine hydrate, mix them in a closed glass container, and stir on a magnetic stirrer for 48 hours at room temperature to obtain hydrazine hydrate-kaolinite intercalation complex and hydrazine hydrate Hydrazine mixture.

[0036] b. Centrifuge the mixture, remove the upper liquid, add absolute ethanol, mix well, centrifuge again, repeat once, wash away excess hydrazine hydrate, and obtain hydrazine hydrate-kaolinite intercalation complex;

[0037] c. Treat the hydrazine hydrate-kaolinite intercalation complex at 60° C. for 2 hours.

[0038] The hydrated kaolinite X-ray diffraction prepared by the above steps figure 1 (c), the interlayer spacing is expanded from 0.72nm of the original stone to 0.84nm, and the obtained hydrated kaolinite content is 83%. Such as figure 1 (c) shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com