Method for processing suspended silicon thermistor

A thermistor and processing method technology, applied in metal material coating technology, technology for producing decorative surface effects, decorative arts, etc. The effect of improving the temperature coefficient of resistance and simplifying the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific implementation examples

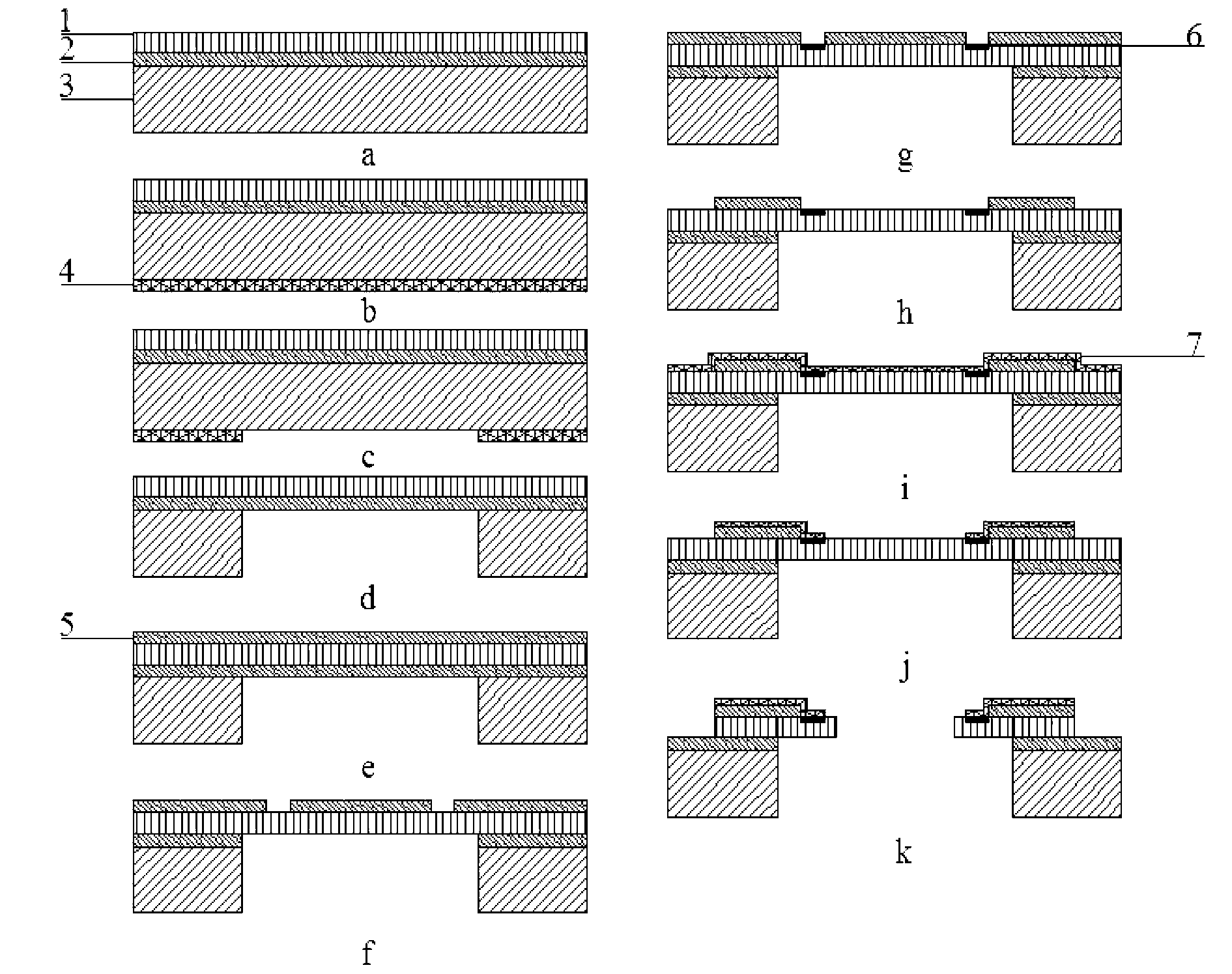

[0027] refer to Image 6 , the silicon suspended thermistor to be processed in the present invention is suspended on the back cavity through the cantilever beam at both ends, and its electrical signal is drawn out through the metal wire on the cantilever beam; the metal wire and the silicon thermistor are in ohmic contact. The processing method of the silicon suspended thermistor comprises the following steps:

[0028] Step 1, cleaning the SOI silicon wafer, removing the native oxide layer and organic contamination on the surface, and then drying; for the SOI silicon wafer used in this example, the device layer silicon 1 has a thickness of 50 μm, the buried oxide layer 2 has a thickness of 1 μm, and the base layer 3 Thickness is 400μm, such as figure 1 (a);

[0029] Step 2, using the SOI silicon wafer as the substrate, magnetron sputtering a layer of AL mask 4 with a thickness of 0.15 μm on the base layer 3 as a mask for etching the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com