Combined rotary gas-solid separation and exhaust all-in-one machine

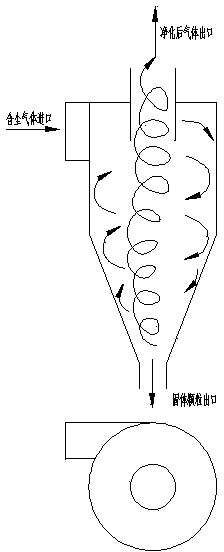

A technology of gas-solid separation and integrated machine, which is applied in the direction of swirling devices and devices in which the axial direction of the swirling flow can be reversed, etc., can solve the problems of complex structure, high one-time investment cost and high operation and maintenance cost of electrostatic precipitator, and achieve The effect of reducing the occupied area, reducing the one-time investment and reducing the amount of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

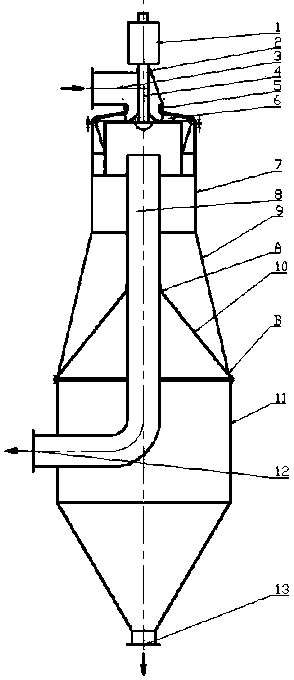

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] Such as figure 2 The combined rotary gas-solid separation and exhaust integrated machine (hereinafter referred to as the integrated machine) is composed of a rotor system and a stator system. The rotor system rotates in the stator system. The rotor system includes a rotating shaft 4 and a shaft mounted on it. Combination impeller 6, the combination impeller 6 includes a wheel disk, and radial blades distributed along the circumference of the wheel disk, the edge of the wheel disk is also provided with axial blades perpendicular to the surface of the wheel disk, and the middle part of the space surrounded by the axial blades is provided with a cone Cylinder, the stator system is a sealed cylindrical structure, from top to bottom there are cover plate, separation cylinder 7, diffusion cone 9, ash hopper 11, and a central air outlet pipe 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com