Preparation method of diatomite-loaded nitrogen-doped nanometer TiO2 photocatalysis material

A technology of photocatalytic materials and diatomite, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of low utilization rate of natural light in photocatalysts, and achieve the effect of improving photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

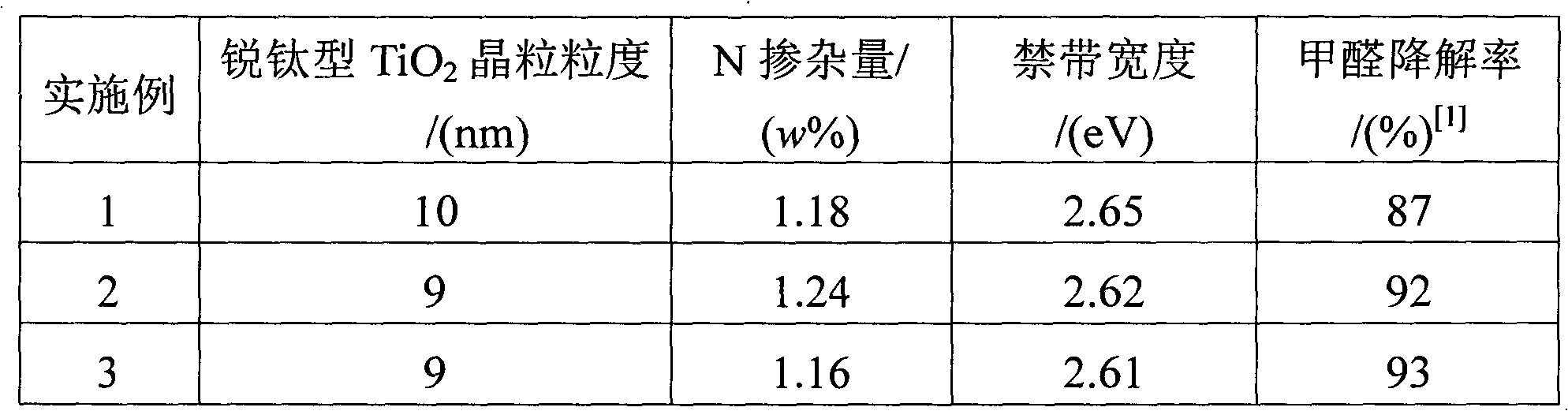

Embodiment 1

[0022] Take 100g of dry diatomite with a diatom content of 84.68% and 3000ml of deionized water to remove the 325-mesh sieve residue and add 100g of deionized water to the laboratory reactor to stir and make slurry, add hydrochloric acid to adjust the pH value of the slurry to 2; A good mass concentration is 200ml of 50% titanium tetrachloride aqueous solution and 150ml of ammonium chloride aqueous solution with a concentration of 200g / L; 30% concentrated ammonia and deionized water are made into an ammonia solution with a volume ratio of 1: 2.0 and added dropwise into the slurry at a rate of 2.4ml / min; stop the dropwise addition when the pH value of the system is 9.0; react at a temperature of 70°C for 2.0h and then filter and wash with water; the washed filter cake is dried at 105°C and beaten After dispersing, heat-preserve and calcinate at 600°C for 2 hours in a laboratory rotary tube furnace under the condition of nitrogen gas.

Embodiment 2

[0024] Take 100g of beneficiation diatom concentrate with a diatom content of 88.39%, add 3000ml of deionized water into a laboratory reactor and stir to make slurry, add hydrochloric acid to adjust the pH value of the slurry to 2; 200ml of titanium tetrachloride aqueous solution and 150ml of ammonium chloride aqueous solution with a concentration of 200g / L; 30% concentrated ammonia water and deionized water are made into an ammonia solution with a volume ratio of 1: 2.0 and added dropwise to the slurry at a rate of 2.4 ml / min; stop dropping when the pH value of the system is 9.0; react at a temperature of 70°C for 2.0h and then filter and wash with water; the washed filter cake is dried and dispersed at 105°C and then rotated in the laboratory Calcination at 600°C for 2 hours under the condition of nitrogen in the furnace.

Embodiment 3

[0026] Take 100g of calcined diatomite with a diatom content of 90.79%, add 3000ml of deionized water into a laboratory reactor and stir to make slurry, add hydrochloric acid to adjust the pH value of the slurry to 2; Titanium chloride aqueous solution 200ml and concentration are 150ml of ammonium chloride aqueous solution of 200g / L; 30% concentrated ammonia water and deionized water are made into the ammonia solution that volume ratio is 1: 2.0 and add dropwise in the slurry, the rate of addition is 2.4ml / min; stop dropping when the pH value of the system is 9.0; react at a temperature of 70°C for 2.0h and then filter and wash with water; the washed filter cake is dried at 105°C and dispersed in a laboratory rotary tube furnace Calcination at 600°C for 2 hours under the condition of medium nitrogen flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com