Method for eliminating static electricity in micro-pill room

A technology of pellets and electrostatics, which is applied in electrostatics, electrical components, and devices that make medicines into special physical or taking forms, etc. Prevention or morbidity, enhancing efficacy, reducing morbidity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Adjust the rotating speed of the main engine of the coating granulator to 60r / min, and the blast pressure to 0.2Pa. Weigh 15Kg of the semi-finished Lemai pills and put them into the coating granulator. After the temperature of the pot body reaches the requirement, spray a certain amount of Soybean oil is relatively moist to the surface of the meatballs, and the medicine can be collected only after there is a smooth oil layer. Considering that the lower the temperature, the smaller the static electricity, the applicant then investigated the temperature of the pan body of the coating granulator. The inspection results are shown in Table 1 below.

[0017] Table 1

[0018]

[0019] Conclusion: It can be seen from Table 1 that when the temperature of the pot body is below 43°C, Lemai Pills will not stick to the composite film.

Embodiment 2

[0021] The composite film is not sticky when the temperature of the pot is below 43°C, but when the temperature of the pot is low, the surface of the meatballs will be too wet, and then there will be adhesion between the meatballs, and finally the actual yield will be reduced. The applicant Statistical investigations were carried out on meatballs at different temperatures, and the results are shown in Table 2 below.

[0022] Table 2

[0023]

[0024] Conclusion: It can be seen from the above table 2 that when the temperature of the pot body is at 40±2°C, the yield is higher.

Embodiment 3

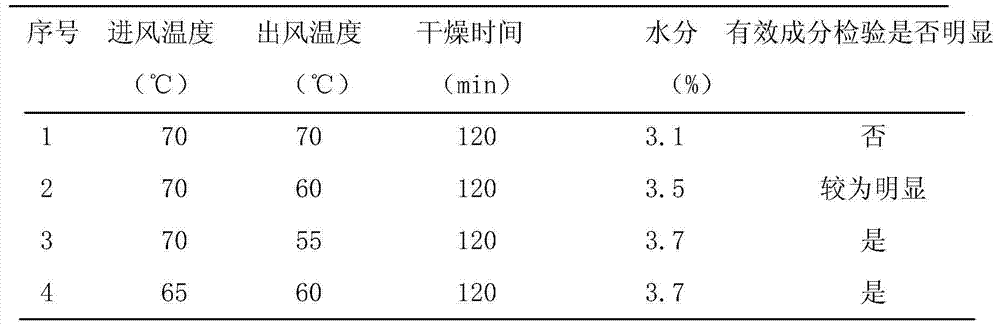

[0026] After spraying medicinal soybean oil, transfer the balls to boiling drying for drying. At this time, the drying temperature is particularly critical. On the one hand, considering the high friction between the balls in boiling drying, high temperature will make static electricity more serious. On the other hand, high temperature Otherwise, the active ingredients in Lemai Pills will volatilize (Lemai Pills contain woody fragrance, and woody fragrance contains volatile oil). The applicant also investigated the temperature of boiling drying. We investigated the experience temperature when no soybean oil was sprayed in the past. The results of the investigation are shown in Table 3 below:

[0027] table 3

[0028]

[0029] Conclusion: It is consistent with the temperature requirement when no soybean oil is sprayed in the past. The effective ingredient identification is obvious when the air inlet temperature is 65-70°C and the outlet air temperature is 60°C.

[0030] Note...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com