Method for preparing multi-core electroluminescent wire

A technology of electroluminescent wire and core wire, which is applied in the application field of electroluminescent devices, and can solve the problems of rough surface ribbing, difficult operation, poor conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

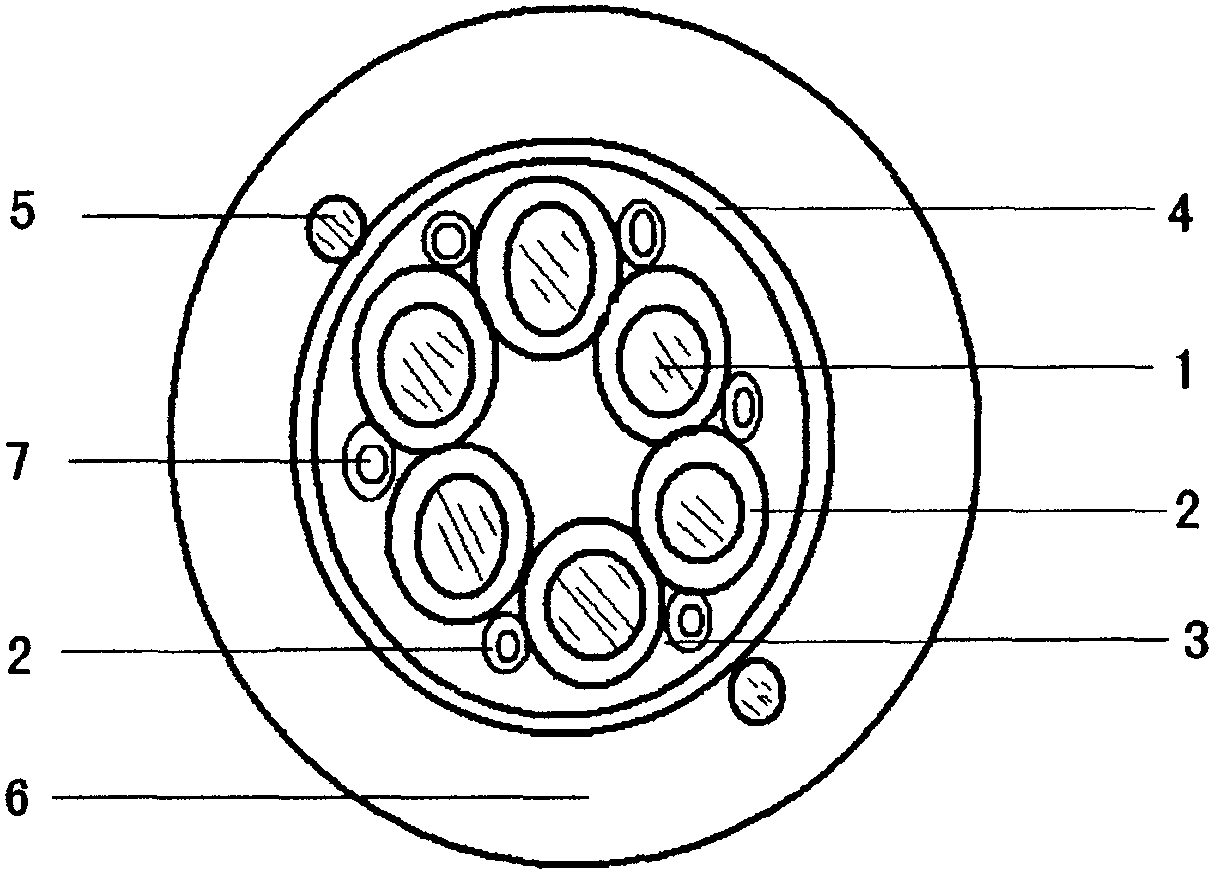

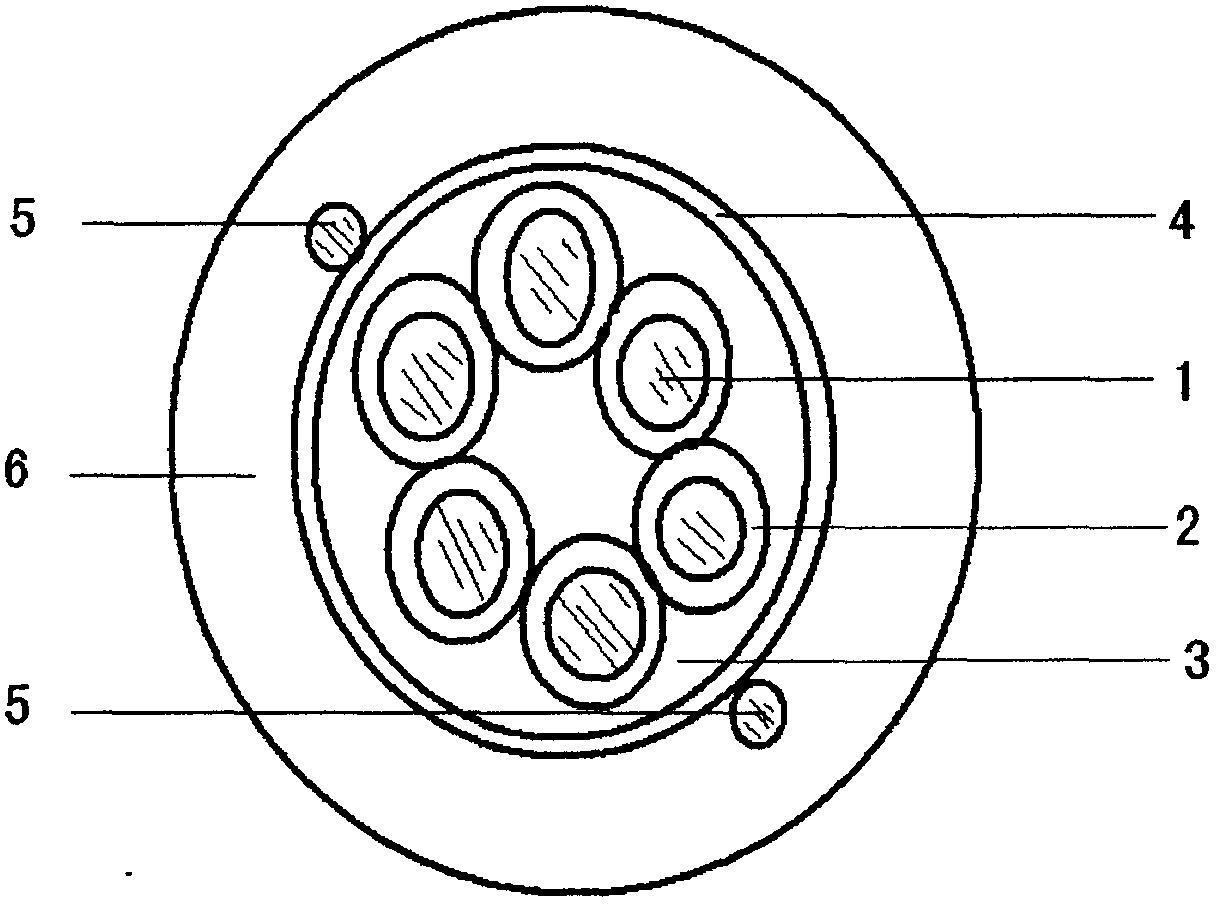

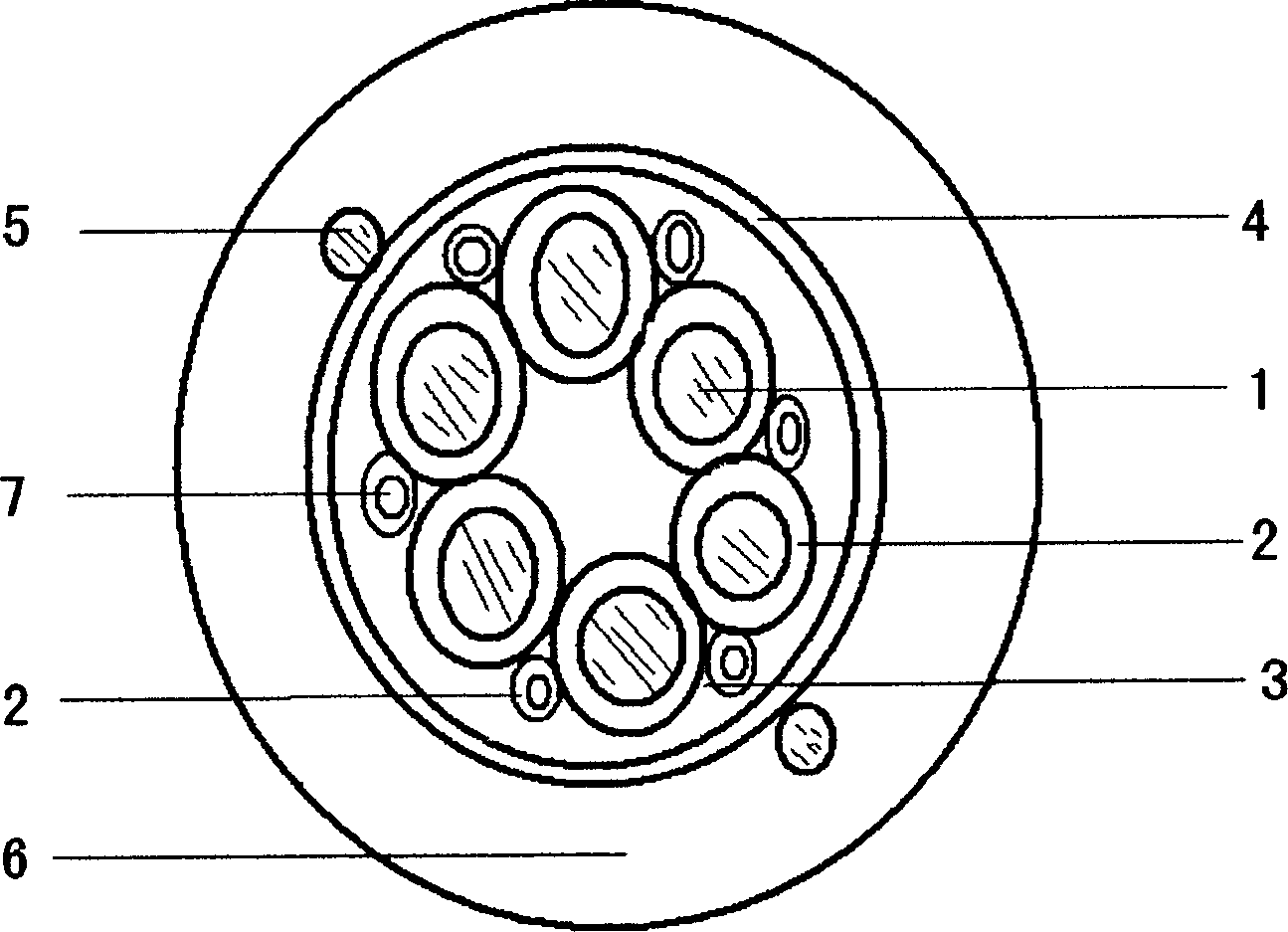

[0042] The metal core wire electrode 1 is a copper wire with good conductivity; the diameter of the wire is 0.2 mm, and its surface is bright and lustrous to remove oily substances.

[0043] Mix 1 part of luminescent material, 2 parts of strontium titanate, and 2 parts of fluorine paint, mix and evenly coat the surface of the metal core wire electrode and dry. The luminescent material uses electroluminescence orange powder. Select 6 pieces, spirally arrange and twist them into one body to complete the luminous insulating layer and winding.

[0044] The distribution electroluminescent material GG44 is mixed with fluorine paint, and its weight ratio is 1:1, which is coated on the outside of the twisted and twisted wire at one time, and dried.

[0045] The transparent conductive layer is coated and dried using nano-ITO with conductive properties.

[0046] Two copper wires with good conductivity are used for the linear electrodes of the outer conductive layer; the diameter is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com