Lithium ion battery pole piece processing method

A lithium ion battery and a processing method technology are applied in the field of lithium ion battery pole piece processing for improving the wettability and liquid absorption of the lithium ion battery pole piece, and can solve the problems of poor wettability and liquid absorption of the battery pole piece, and achieve good performance, improve liquid absorption performance, improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

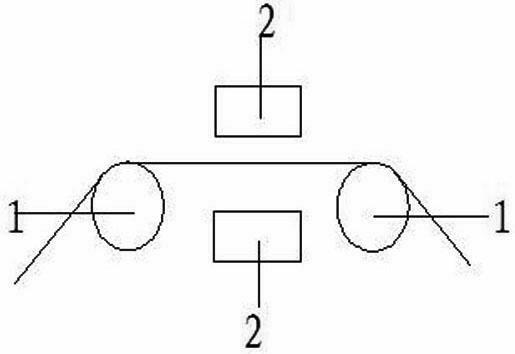

[0021] Embodiment 1: the cold-pressed cathode pole piece is placed in such as figure 1 On the guide roller 1 of the shown device, two corona treatment machines 2 are respectively located directly above and directly below the cathode sheet. The cathode pole piece passes through the corona treatment machine 2 under the traction of the guide roller 1, and the two surfaces of the cathode pole piece are applied with high-voltage alternating frequency voltage, which generates a large amount of low-temperature plasma to bombard the surface of the material and enter the molecular structure of the material, making the material The surface molecules are polarized, thereby increasing the surface energy of the pole piece. At the same time, it promotes the breakage of chemical bonds, resulting in more hydrophilic atomic groups or functional groups such as hydroxyl groups, carbon groups, and hydrogen peroxide bonds, so as to improve the wettability of the electrolyte to the pole piece and i...

Embodiment 2

[0023] Embodiment 2: place the cathode pole piece after cutting on such as figure 2 On the guide roller 1 of the shown device, the corona treatment machine 2 is located directly above the cathode electrode sheet. The cathode pole piece passes through the corona treatment machine 2 under the traction of the guide roller 1, and the surface of the cathode pole piece close to the corona treatment machine 2 is applied with high-voltage alternating frequency voltage to generate a large amount of low-temperature plasma bombarding the surface of the material and entering the molecular structure of the material , to polarize the surface molecules of the material, thereby increasing the surface energy of the pole piece. At the same time, it promotes the breakage of chemical bonds, resulting in more hydrophilic atomic groups or functional groups such as hydroxyl groups, carbon groups, and hydrogen peroxide bonds, so as to improve the wettability of the electrolyte to the pole piece and ...

Embodiment 3

[0025] Embodiment 3: The cathode pole piece that is welded with lug is placed on such as figure 1 On the guide roller 1 of the shown device, the corona treatment machine 2 is respectively located directly above and directly below the cathode sheet. The cathode pole piece passes through the corona treatment machine 2 under the traction of the guide roller 1, and the two surfaces of the cathode pole piece are applied with high-voltage alternating frequency voltage, which generates a large amount of low-temperature plasma to bombard the surface of the material and enter the molecular structure of the material, making the material The surface molecules are polarized, thereby increasing the surface energy of the pole piece. At the same time, it promotes the breakage of chemical bonds, resulting in more hydrophilic atomic groups or functional groups such as hydroxyl groups, carbon groups, and hydrogen peroxide bonds, so as to improve the wettability of the electrolyte to the pole pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com