Method for copolymerizing carbon dioxide and propylene oxide with circulation flow reactor

A loop reactor and carbon dioxide technology, which is applied in the field of copolymerizing carbon dioxide and propylene oxide using loop reactors, achieves the effects of good gas-liquid contact and mass transfer, low production cost and small kinetic energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

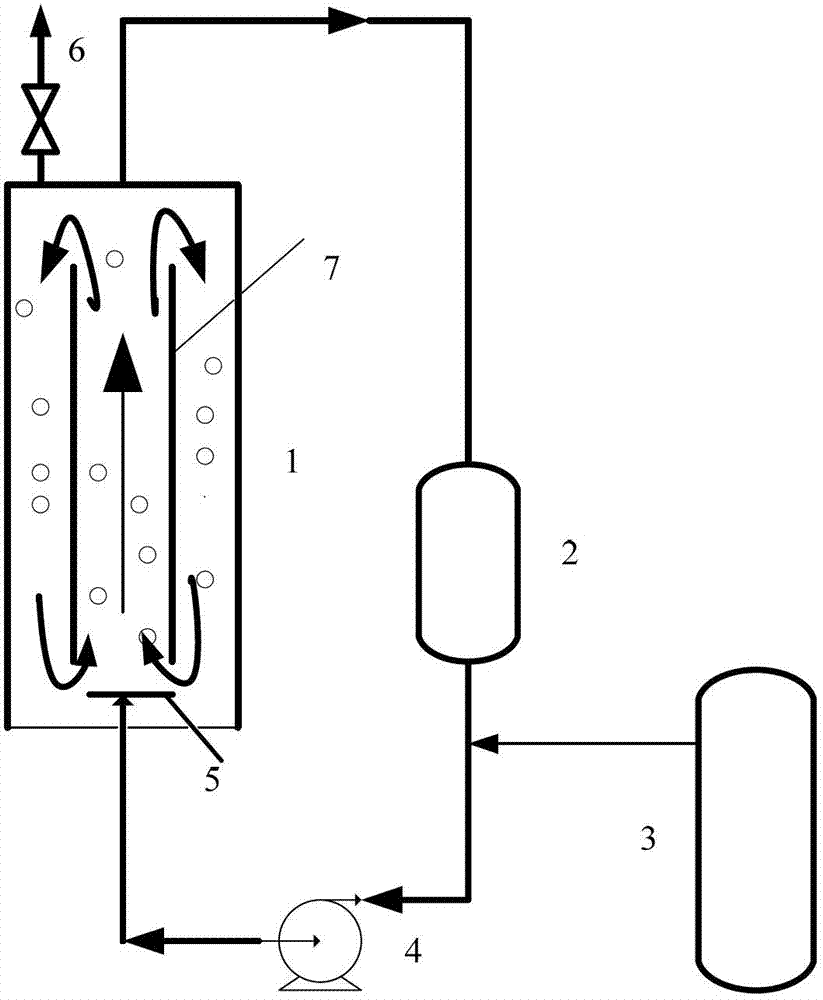

[0044] in such as figure 1 In the loop reactor shown, carbon dioxide (commercially available industrial gas with a purity of 99.9%, dehydrated and deoxidized) and propylene oxide (analytically pure, dehydrated and deoxidized) were used as raw materials, and a rare earth three-way catalyst and carboxyl The acid-zinc mixed solution is used as a catalyst. When the reaction temperature is 70°C and the pressure is 35 atmospheres, the reaction time is 4 hours. The reaction product is analyzed by Bruker 300MHz nuclear magnetic spectrum, Nicholas 401 infrared molecular spectrum, Agilent 7890A gas chromatography and other analytical instruments. The qualitative and quantitative analysis of each substance was carried out in combination with the separation and purification method, and the results showed that the conversion rate of propylene oxide was 50%, and the selectivity of aliphatic polycarbonate was about 90%. 1 H nuclear magnetic spectrum has characteristic peaks at δ=5.0, 4.2, 3....

Embodiment 2

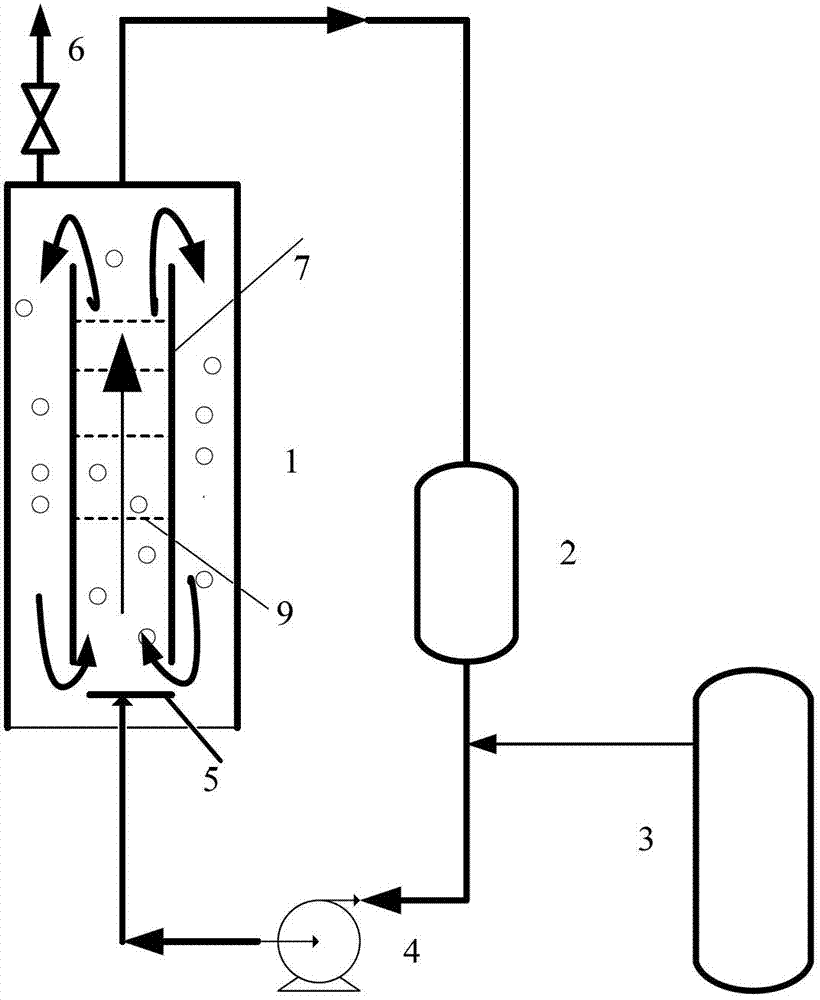

[0046] In addition to figure 2 The loop reactor shown in place of figure 1In the shown loop reactor, except that three layers of large-pore sieve plates are arranged in the draft tube, the reaction is carried out in the same way as in Example 1, and the same analytical method is used for qualitative and quantitative analysis. The results show that the conversion rate of propylene oxide 60%, the selectivity of aliphatic polycarbonate is about 92%.

Embodiment 3

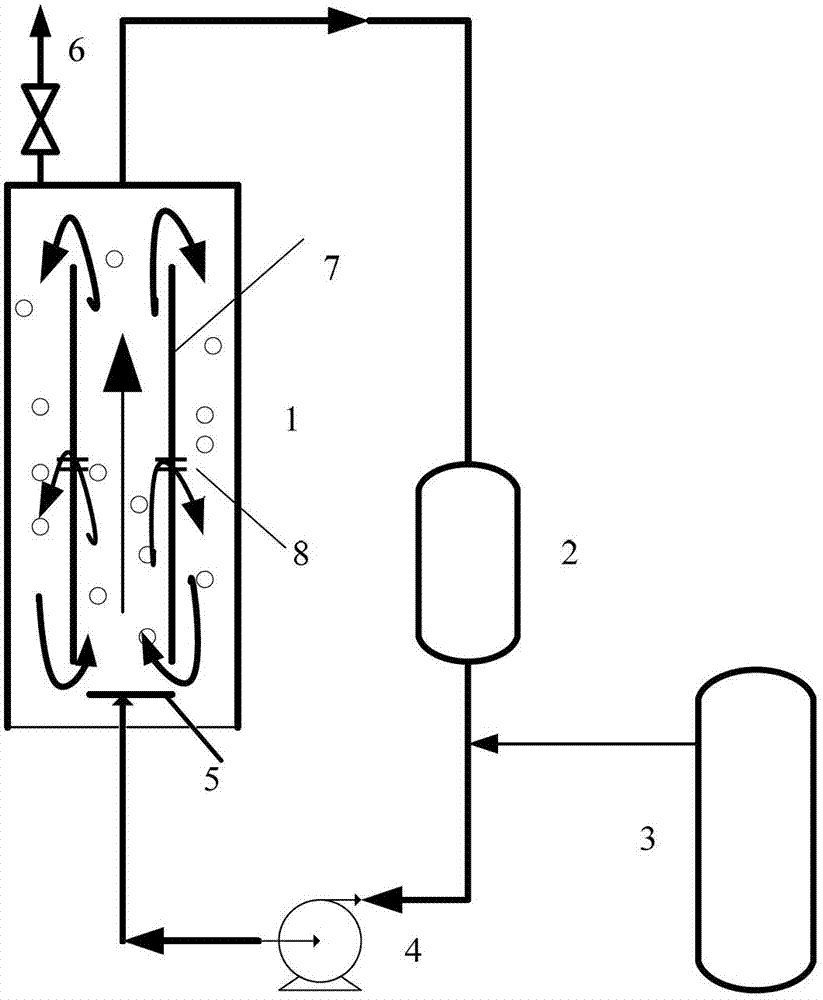

[0048] in such as image 3 In the loop reactor shown, carbon dioxide, nitrogen (commercially available industrial gas with a purity of 99.9%, after dehydration and deoxidation treatment) and propylene oxide are used as reaction raw materials, and a rare earth three-way catalyst and a mixed solution of zinc carboxylate are used as catalysts, and Dioxane was added as a solvent (analytically pure, and dehydrated and deoxidized). When the reaction temperature was 75°C and the pressure was 35 atmospheres, the reaction time was 7 hours, the conversion rate of propylene oxide was 90%, and the aliphatic polycarbonate The selectivity is about 94%.

[0049] According to the above experimental results, it can be seen that using the loop reactor according to the present invention, especially a large-pore sieve plate is arranged in the draft tube, or a loop reactor with a plurality of holes evenly distributed at a certain height of the draft tube wall Among them, the conversion rate of pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com