Trapezoidal distributing cylinder with strip-shaped net

A trapezoidal distribution, strip-shaped technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of easy deformation, increased catalyst breakage rate, thin plate impact resistance, poor pressure resistance, etc., to reduce friction. and collision, reducing flow resistance, good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

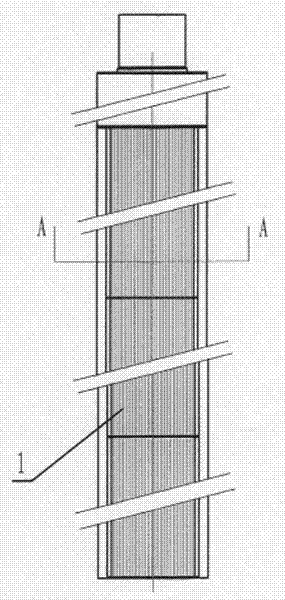

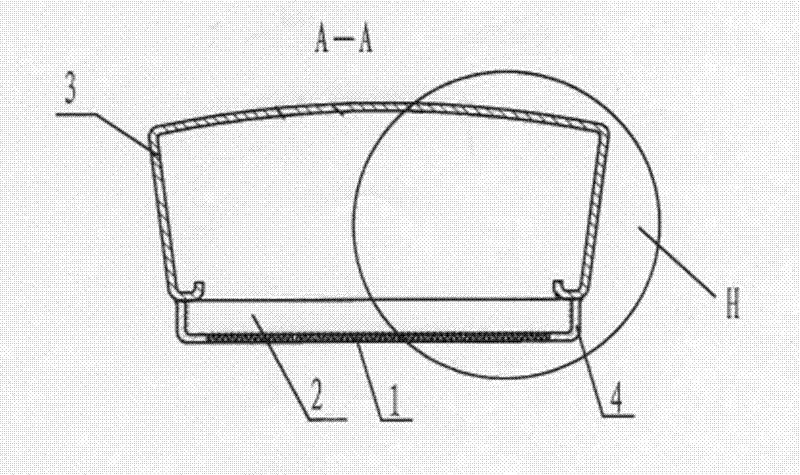

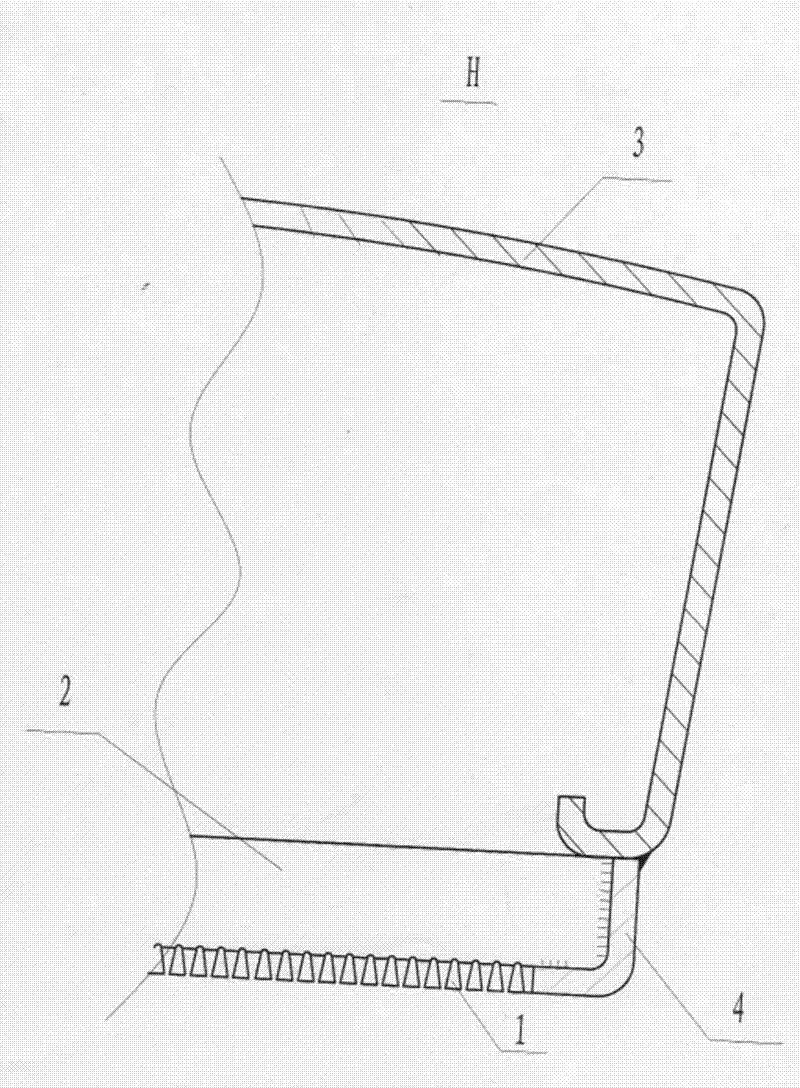

[0013] Strip net trapezoidal distribution cylinder, including trapezoidal support plate 2, support plate connection frame 4, arc-shaped back shell plate 3, and mesh strip 1. There are multiple trapezoidal support plates 2, which are evenly arranged in the support plate connection frame 4 at equal distances, and welded on the support plate connection frame 4, and a plurality of mesh strips 1 are axially arranged at a set distance. On a trapezoidal support plate 2 equidistantly arranged, its cross-section of the mesh bar 1 is an isosceles triangle, and is welded vertically at 90° with the trapezoidal support plate 2 with an inverted triangle to form a strip net. The arc-shaped rear shell plate 3 of the overall structure is fixedly connected to the support plate connection frame 4 to form a trapezoidal tube, forming a strip-shaped net trapezoidal distribution tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com