Carbon nanofiber load titanium dioxide thin film anode material and preparation method thereof

A technology of carbon nanofiber and titanium dioxide, which is applied in the direction of battery electrodes, structural parts, electrical components, etc., to achieve strong controllability, performance improvement, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

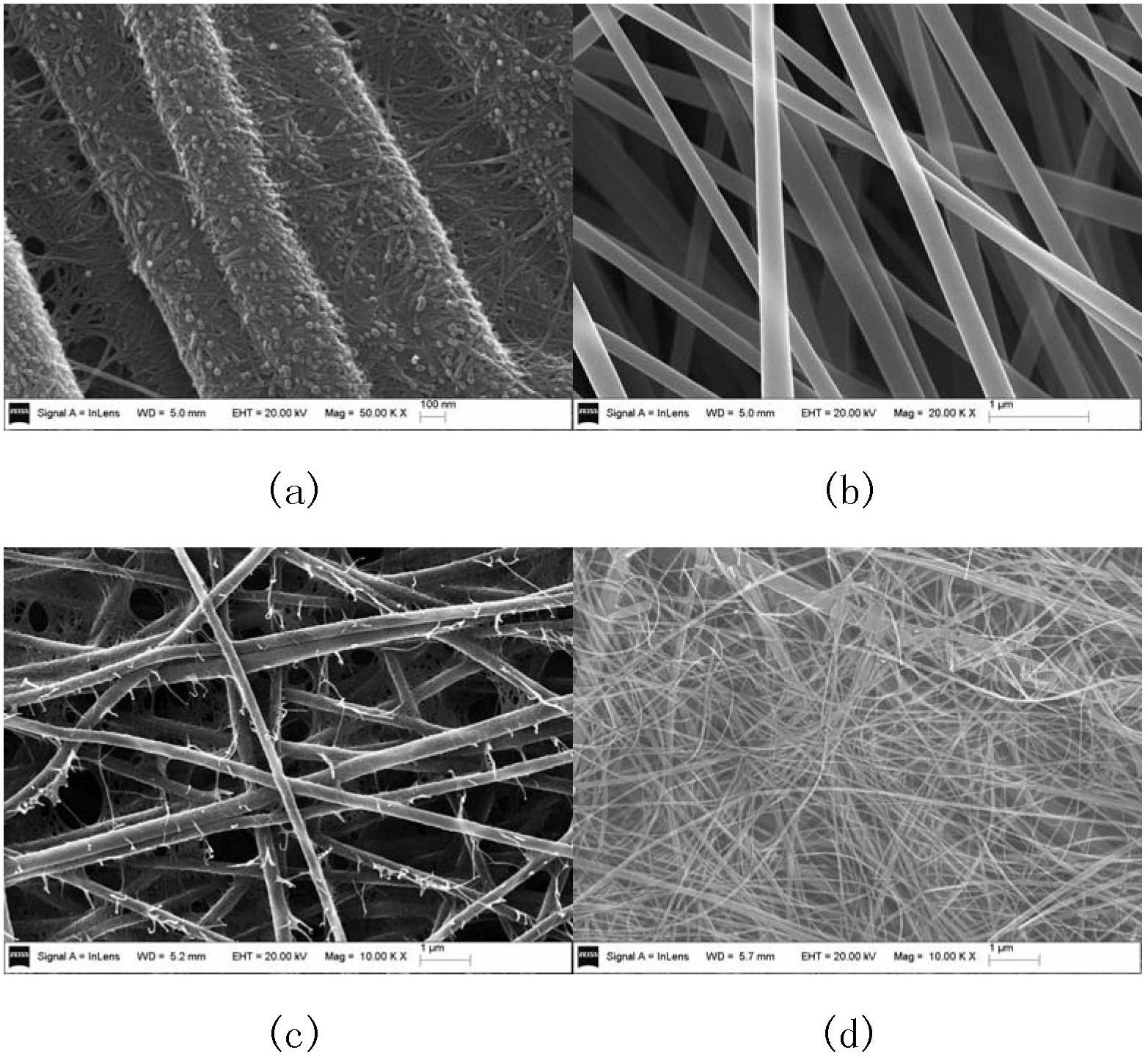

[0045] Add 3ml of tetra-n-butyl titanate and 2ml of anhydrous acetic acid and the mixed solution to 60ml of polyacrylonitrile (concentration is 9wt%) and polymethyl methacrylate (concentration is 3wt%) in the dimethylformamide solution, Forms a homogeneous solution for electrospinning.

[0046] During the electrospinning process, a No. 12 injection needle (inner diameter of 1.1mm) was selected, the applied electrostatic voltage was 18kV, the flow rate of the spinning solution was 0.6ml / h, and the receiving distance between the metal roller and the needle was 20cm. The radial speed is 8m / s, and after 5 hours of spinning, a partially parallel-oriented nanofiber membrane with a certain thickness is obtained.

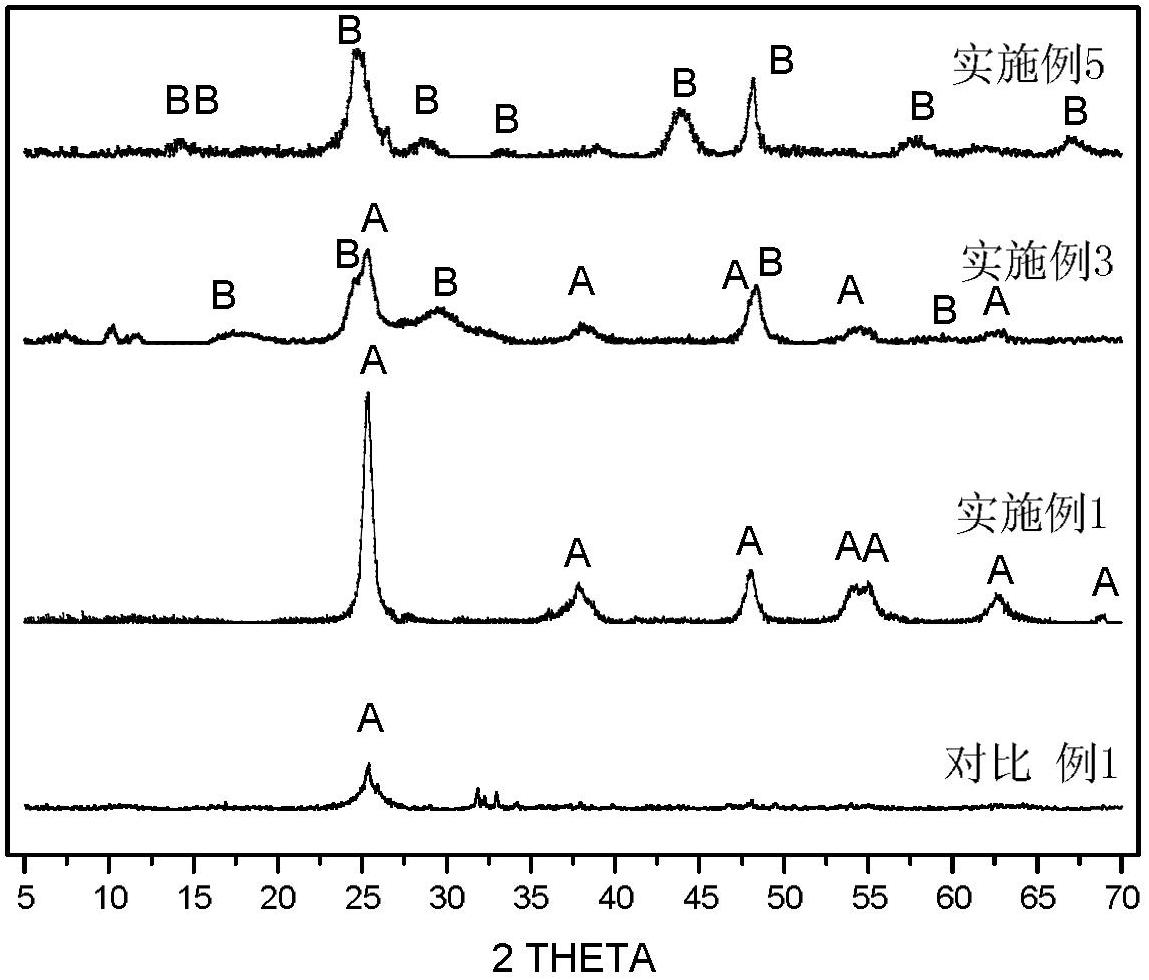

[0047] The obtained electrospun nanofibrous membrane was subjected to constant strain pre-oxidation at 280 °C for 5 h, and then placed in a carbonization furnace at 600 °C under the protection of high-purity nitrogen for 2 h. The carbon nanofiber-loaded titanium dioxide na...

Embodiment 2

[0052] Add 6ml of tetra-n-butyl titanate and 4ml of anhydrous acetic acid and the mixed solution to 60ml of polyacrylonitrile (concentration is 9wt%) and polymethylmethacrylate (concentration is 3wt%) in the dimethylformamide solution, Forms a homogeneous solution for electrospinning. After electrospinning, pre-oxidation and carbonization, the preparation of carbon nanofiber-supported titanium dioxide nanoparticle composite film refers to Example 1.

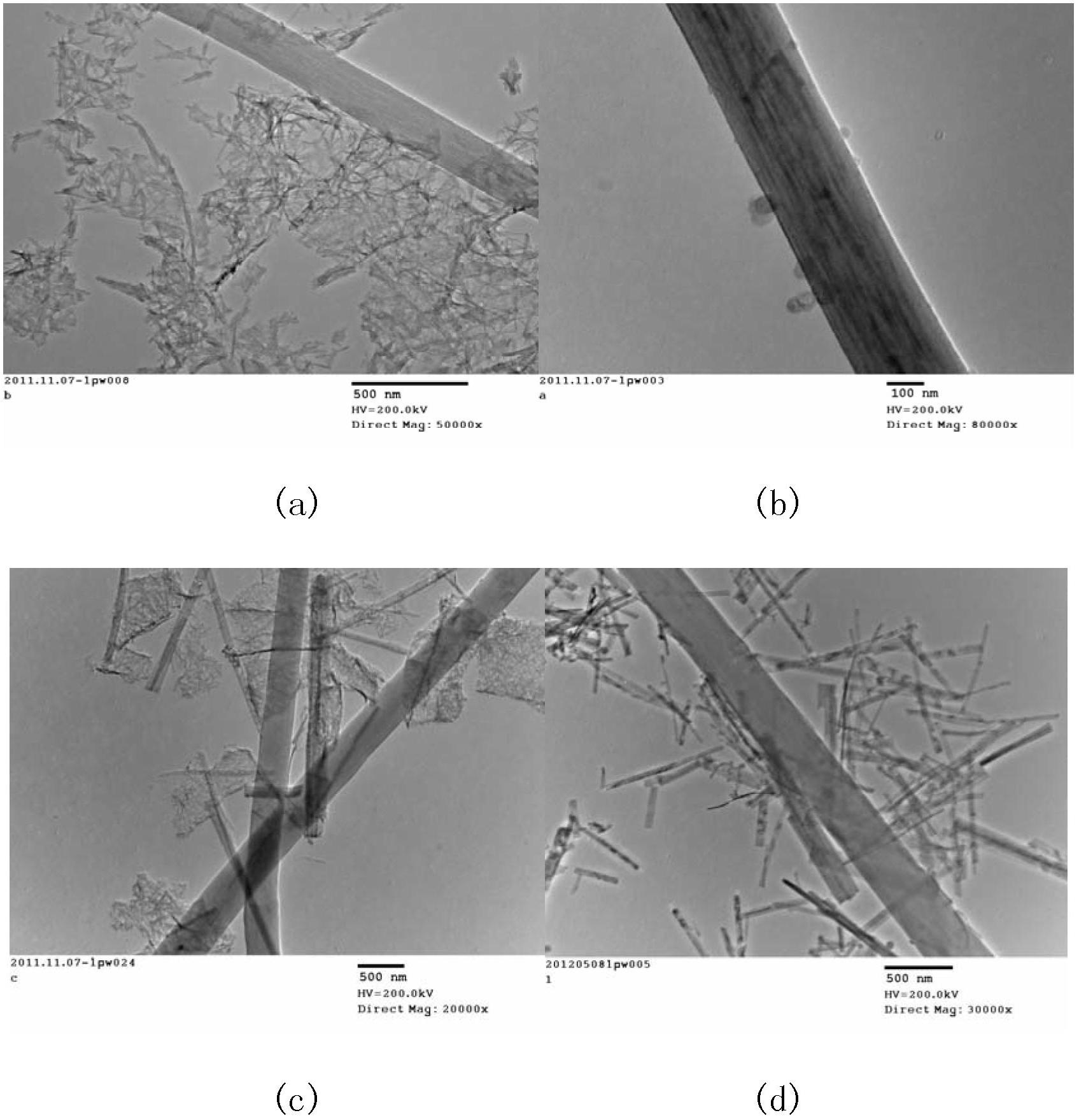

[0053] The composite film was immersed in 10mol / L sodium hydroxide aqueous solution, transferred to a polytetrafluoroethylene-lined hydrothermal reactor, and kept in a vacuum oven at 230°C for 12 hours to obtain carbon nanofiber-supported sodium titanate nanotubes .

[0054] The composite film was taken out and washed with deionized water to pH = 7, immersed in an aqueous hydrochloric acid solution with pH = 2, and left at room temperature for 24 hours to obtain titanate nanotubes supported by carbon nanofibers, and the shape an...

Embodiment 3

[0057] Add 6ml of tetra-n-butyl titanate and 4ml of anhydrous acetic acid and the mixed solution to 60ml of polyacrylonitrile (concentration is 9wt%) and polymethylmethacrylate (concentration is 3wt%) in the dimethylformamide solution, Forms a homogeneous solution for electrospinning. After electrospinning, pre-oxidation and carbonization, the preparation of carbon nanofiber-supported titanium dioxide nanoparticle composite film refers to Example 1.

[0058] The composite film was immersed in 10mol / L sodium hydroxide aqueous solution, transferred to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and kept in a vacuum oven at 230°C for 50 hours to obtain carbon nanofiber-supported sodium titanate nanoparticles. Tube and nanowire hybrid.

[0059] Take out the composite film and wash it with deionized water to pH = 7, immerse in an aqueous hydrochloric acid solution with pH = 2, and place it at room temperature for 24 hours to obtain a mixture of nanotubes and nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Gap size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com