Organic multi-component carrier lead ion selective electrode and preparation method thereof

A technology of selecting electrodes and multi-components, which is applied in the field of analysis and measurement, and achieves the effects of simple preparation, good linearity and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

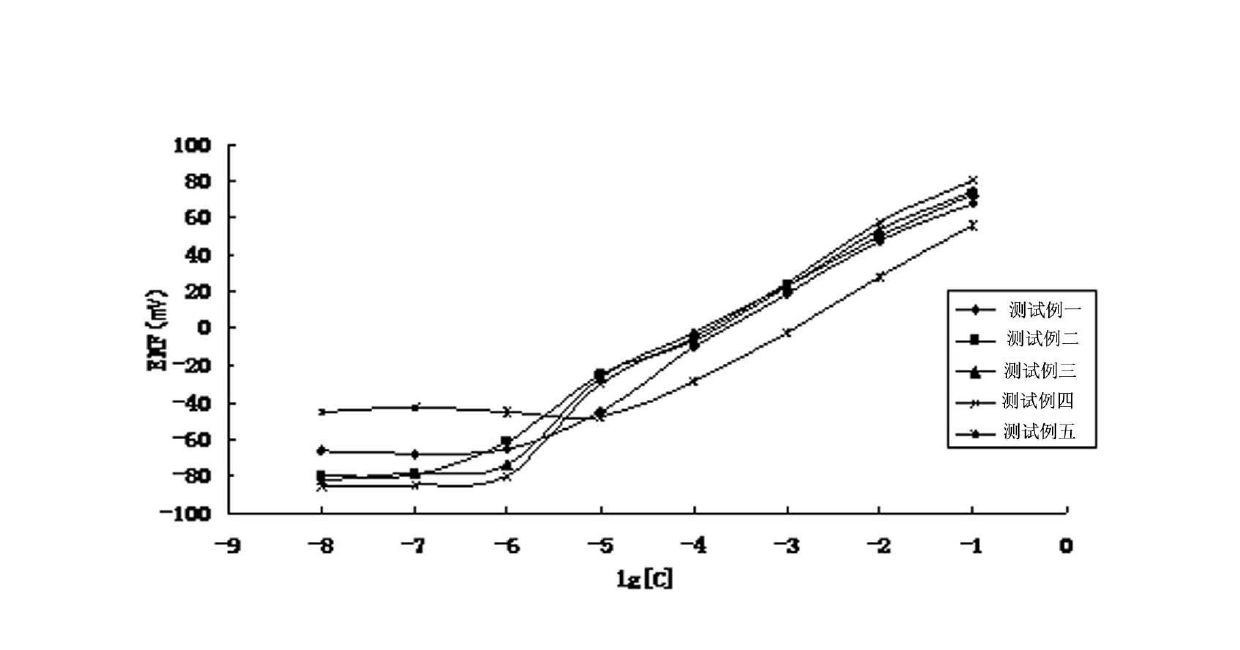

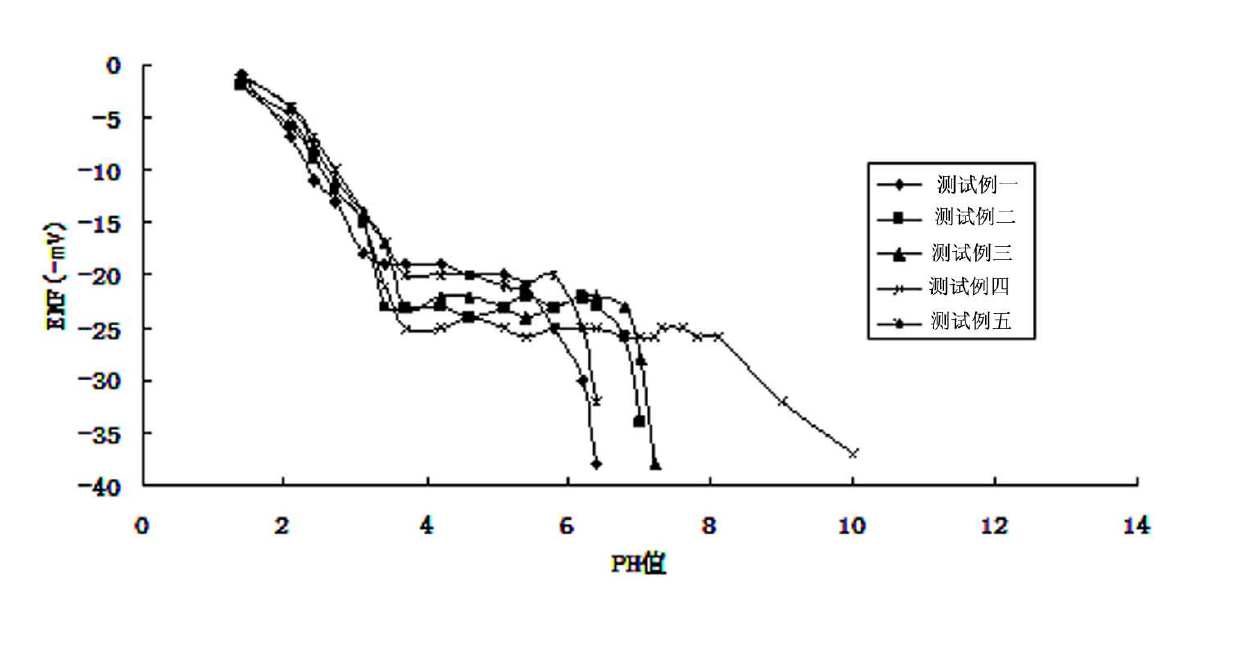

[0030] Example 1: Preparation of a single component of tetraphenylporphyrin as a carrier and its membrane (blank control)

[0031] Dissolve 0.006g tetraphenylporphyrin in 5mL THF, ultrasonically disperse for 5min, then add 0.006g NaTPB, 0.2mL DBP, 0.2g PVC powder, and ultrasonically disperse intermittently for 10min. The above solution was poured into a glass ring with a diameter of 80 mm stuck on a glass sheet, and dried naturally at room temperature for 24 hours to obtain a flexible and elastic selective membrane.

Embodiment 2

[0032] Example 2: Preparation of Tetraphenylporphyrin and Dimethyl Sulfide Blend as Carrier and Film

[0033] Dissolve 0.003g tetraphenylporphyrin, 0.003g dimethyl sulfide in 5mL THF, ultrasonically disperse for 5min, then add 0.006g NaTPB, 0.2mLDBP, 0.2gPVC powder, intermittently ultrasonically disperse for 10min. The above solution was poured into a glass ring with a diameter of 80 mm stuck on a glass sheet, and dried naturally at room temperature for 24 hours to obtain a flexible and elastic selective membrane.

Embodiment 3

[0034] Example 3: Preparation of Tetraphenylporphyrin and Triphenylphosphine Blend as a Carrier and Its Membrane

[0035] Dissolve 0.003g tetraphenylporphyrin and 0.003g triphenylphosphine in 5mL THF, ultrasonically disperse for 5min, then add 0.006g NaTPB, 0.2mLDBP, 0.2gPVC powder in sequence, and ultrasonically disperse intermittently for 10min. The above solution was poured into a glass ring with a diameter of 80 mm stuck on a glass sheet, and dried naturally at room temperature for 24 hours to obtain a flexible and elastic selective membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com