Wooden floor mounting structure

A technology for installing structures and floors, which is applied to building structures, floors, insulation layers, etc., can solve the problems of serious dust pollution, loud on-site noise, and high installation costs, and achieve the effects of firm connection, reduced installation links, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

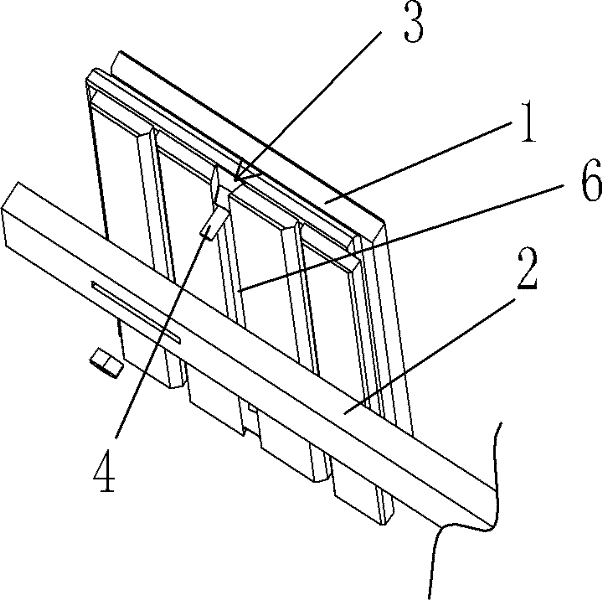

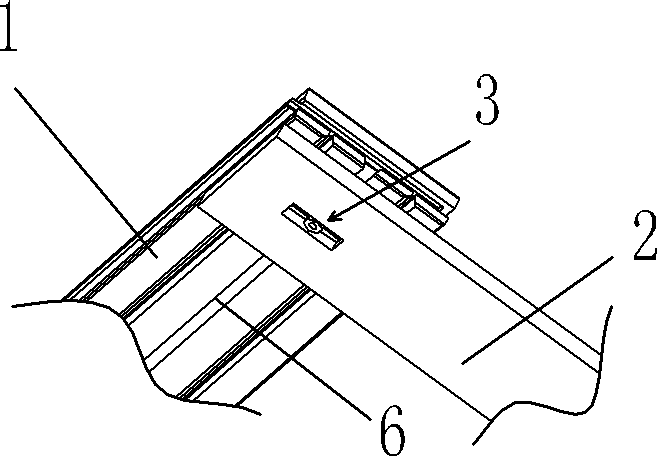

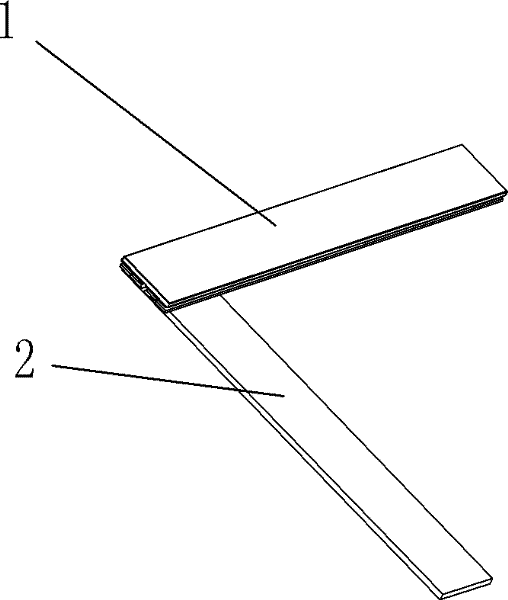

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

[0038] As shown in the figure, the wooden floor installation structure includes a wooden floor 1 and a base plate 2 placed under the wooden floor 1. A device is provided between the bottom surface of the wooden floor 1 and the base plate 2 to fix the wooden floor 1 on the base plate 2. The fixed connection structure 3. The wooden floor 1 is fixedly connected to the bottom plate 2, and at the same time, an interlocking structure can be provided between adjacent wooden floors.

[0039] Specifically, the fixed connection structure 3 can be implemented in several ways:

[0040] The first embodiment: the fixed connection structure 3 includes a first connection groove arranged at the bottom of the wooden floor 1, a second connection groove is provided on the bottom plate 2, and the first connection groove and the second connection groove pass through The fixed connector 4 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com