Material preparation process for preparing dissolving pulp by modifying bleached bamboo-wood composite pulp

A bamboo-wood composite and bamboo pulp technology is applied in the post-treatment modification of cellulose pulp, raw material separation, pre-treatment with alkaline compounds, etc., which can solve the problems of discomfort, low quality of dissolving pulp and high cost, and achieve cost reduction. , The material preparation process is easy and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

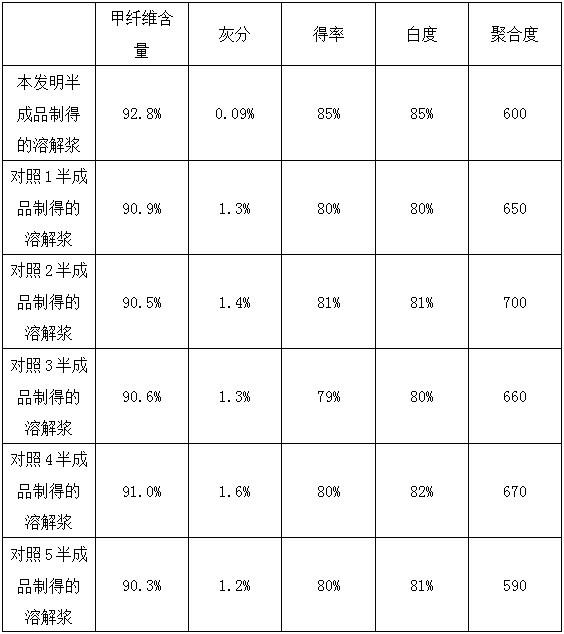

Examples

Embodiment 1

[0053] A material preparation process for preparing dissolving pulp by modifying bleached bamboo-wood composite pulp, comprising the following process steps:

[0054] A. Raw material preparation

[0055] According to the ratio of the total weight of bleached bamboo pulp and bleached wood pulp to the volume of the digester: 100kg: 1m 3 Prepare raw materials, select bleached bamboo pulp and bleached wood pulp;

[0056] B. Scatter and slice

[0057] Dispersing bleached bamboo pulp and bleached wood pulp into pulp boards and cutting bleached bamboo pulp boards and bleached wood pulp boards into small pieces;

[0058] C. Dipping

[0059] The dispersed and sliced bleached bamboo pulp and bleached wood pulp are mixed with sodium hydroxide solution to obtain a mixture of bleached bamboo pulp, bleached wood pulp and sodium hydroxide solution, that is, pulp porridge, and the control liquid ratio is 1:3. The solid weight of sodium hydroxide in the sodium hydroxide solution is 17% o...

Embodiment 2

[0062] A material preparation process for preparing dissolving pulp by modifying bleached bamboo-wood composite pulp, comprising the following process steps:

[0063] A. Raw material preparation

[0064] According to the ratio of the total weight of bleached bamboo pulp and bleached wood pulp to the volume of the digester is 250kg: 1m 3 Prepare raw materials, select bleached bamboo pulp and bleached wood pulp;

[0065] B. Scatter and slice

[0066] Dispersing bleached bamboo pulp and bleached wood pulp into pulp boards and cutting bleached bamboo pulp boards and bleached wood pulp boards into small pieces;

[0067] C. Dipping

[0068] The bleached bamboo pulp and bleached wood pulp dispersed and sliced are mixed with sodium hydroxide solution to obtain a mixture of bleached bamboo pulp, bleached wood pulp and sodium hydroxide solution, namely pulp porridge. The control liquid ratio is 1:4, The solid weight of sodium hydroxide in the sodium hydroxide solution is 22% of th...

Embodiment 3

[0071] A material preparation process for preparing dissolving pulp by modifying bleached bamboo-wood composite pulp, comprising the following process steps:

[0072] A. Raw material preparation

[0073] According to the ratio of the total weight of bleached bamboo pulp and bleached wood pulp to the volume of the digester is 175kg: 1m 3 Prepare raw materials, select bleached bamboo pulp and bleached wood pulp;

[0074] B. Scatter and slice

[0075] Dispersing bleached bamboo pulp and bleached wood pulp into pulp boards and cutting bleached bamboo pulp boards and bleached wood pulp boards into small pieces;

[0076] C. Dipping

[0077] Mix bleached bamboo pulp and bleached wood pulp with sodium hydroxide solution after dispersing and slicing to obtain a mixture of bleached bamboo pulp, bleached wood pulp and sodium hydroxide solution, that is, pulp porridge. The control liquid ratio is 1:3.5, The solid weight of sodium hydroxide in the sodium hydroxide solution is 19.5% of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com