Method for improving gassing resistance of transformer oil and equipment for producing transformer oil

A technology for transformer oil and anti-gas evolution, applied in the petrochemical field, can solve the problems of difficult industrialization, high catalyst selectivity requirements, and difficulty in controlling the depth of hydrogenation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

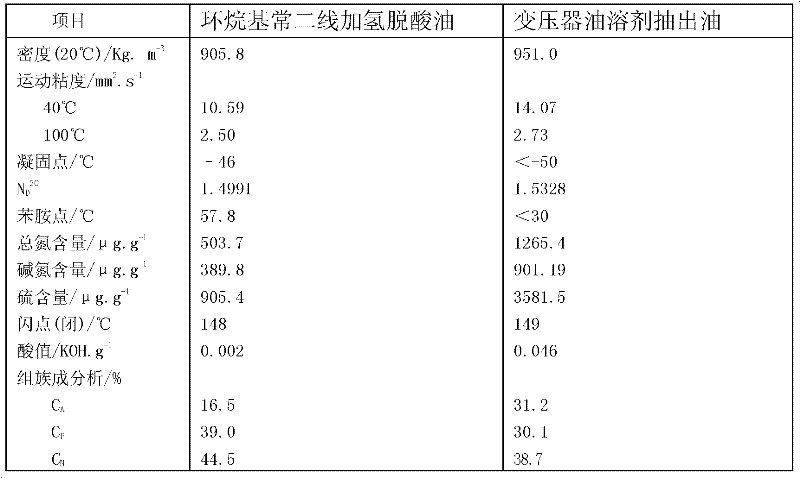

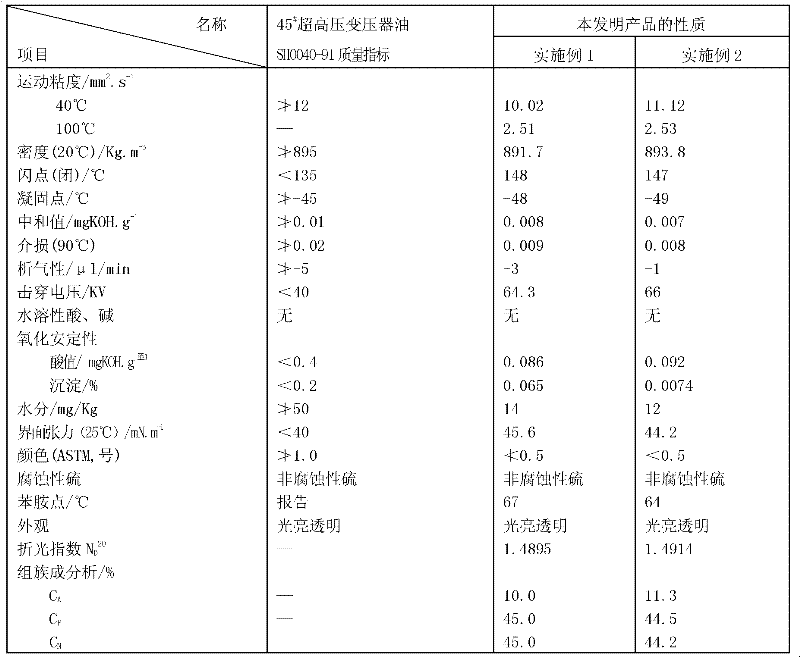

[0024] For the first time, the naphthenic second-line hydrodeacidification oil and the extracted oil of the transformer oil fraction are mixed as the raw material oil at a mass ratio of 3.0:7.0, and the solvent extraction and separation process is carried out, and then the solvent refining method of the present invention is implemented.

[0025] (1) The first solvent extraction and separation process

[0026] The refining conditions of the extraction tower 1 are as follows: the temperature at the top of the tower is 55° C., the temperature at the bottom of the tower is 35° C., and the mass ratio of the solvent furfural to the raw material oil is 2:1. A part of the raffinate obtained after stripping and removing the solvent from the raffinate at the top of the extraction tower 1 is returned to the extraction tower 1 through pipelines, and the specific conditions are shown in (2) below.

[0027] (2) solvent refining process of the present invention

[0028]Naphthenic second-lin...

Embodiment 2

[0030] For the first time, the furfural extracted oil of naphthenic second-line hydrodeacidification oil is used as raw material oil, and the solvent extraction and separation process is carried out, and then the solvent refining method of the present invention is implemented.

[0031] (1) The first solvent extraction and separation process

[0032] The refining conditions of the extraction tower 1 are: the temperature at the top of the tower is 45° C., the temperature at the bottom of the tower is 35° C., and the mass ratio of the solvent furfural to the raw oil lubricating oil solvent extraction oil is 2.5:1. Part of the raffinate obtained from the top of the extraction tower 1 is returned to the extraction tower 1 through the pipeline, and the specific conditions are shown in (2) below.

[0033] (2) solvent refining process of the present invention

[0034] Use transformer oil solvent extracted oil as raw material oil, and carry out furfural refining together with (1) part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com