White ink suitable for solvent-free glue compositing and preparation method thereof

A solvent-free, white ink technology, applied in inks, applications, household appliances, etc., can solve the problems of low molecular weight of solvent-free adhesives, dark composite products, composite products scrapped, etc., achieve high density, prevent white spots, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] One, with the ethyl acetate of 15% (percentage by weight), the n-propyl acetate of 70% (percentage by weight) dissolves 15% (percentage by weight) of the modified ternary chlorinated vinegar resin and obtains 15% modified ternary chlorinated vinegar Resin liquid.

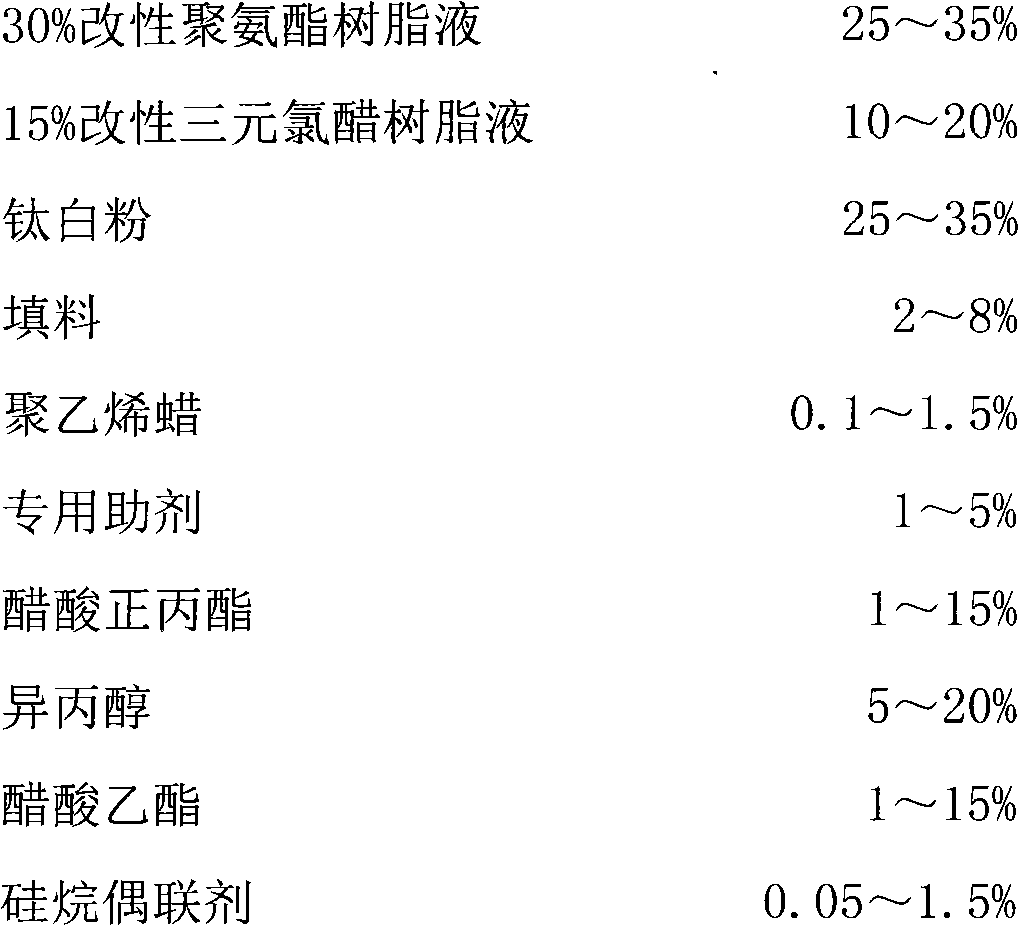

[0030] 2. The specific components of white ink suitable for solvent-free adhesive compounding are as follows:

[0031]

[0032]

[0033] 3. The preparation method of the above white ink suitable for solvent-free adhesive compounding is:

[0034] 1) Raw materials for primary dispersion: Put all the 15% modified ternary vinyl chloride resin liquid and special additives in the raw materials into the dispersion tank, and slowly add titanium dioxide, fillers, and polyethylene at a stirring speed of 200 rpm For wax, increase the rotation speed to 1500 rpm, and disperse at high speed for 10 to 15 minutes;

[0035] 2) Secondary dispersing and grinding: put 40% of n-propyl acetate and isopropanol into the abov...

Embodiment 2

[0038] One, with the ethyl acetate of 12% (percentage by weight), the n-propyl acetate of 73% (percentage by weight) dissolves 15% (percentage by weight) of the modified ternary chlorinated vinegar resin and obtains 15% modified ternary chlorinated vinegar Resin liquid.

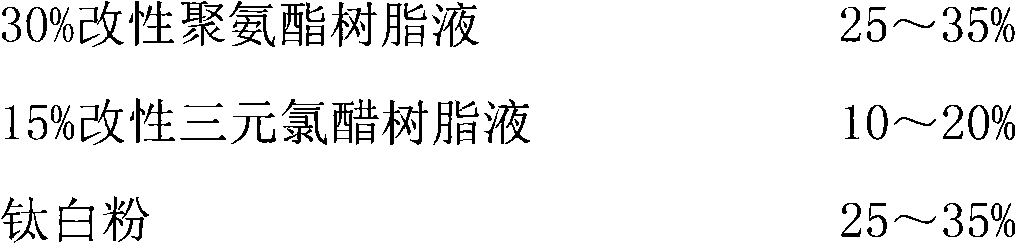

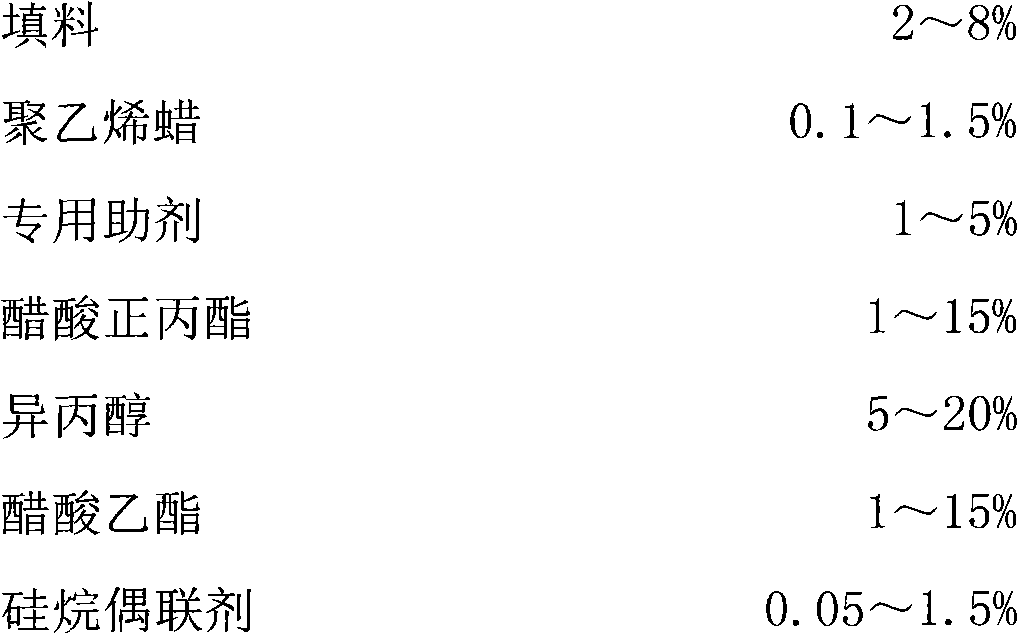

[0039] 2. The specific components of white ink suitable for solvent-free adhesive compounding are as follows:

[0040]

[0041] 3. The preparation method of the above white ink suitable for solvent-free adhesive compounding is:

[0042] 1) Raw materials for primary dispersion: Put all the 15% modified ternary vinyl chloride resin liquid and special additives in the raw materials into the dispersion tank, and slowly add titanium dioxide, fillers, and polyethylene at a stirring speed of 200 rpm For wax, increase the rotation speed to 1500 rpm, and disperse at high speed for 10 to 15 minutes;

[0043] 2) Secondary dispersing and grinding: put 50% of n-propyl acetate and isopropanol into the above-mentioned ...

Embodiment 3

[0046] One, make 15% modified ternary chlorinated vinegar with 15% (percentage by weight) of the n-propyl acetate dissolving 15% (percentage by weight) of ethyl acetate, 71% (percentage by weight) Resin liquid.

[0047] 2. The specific components of white ink suitable for solvent-free adhesive compounding are as follows:

[0048]

[0049] 3. The preparation method of the above white ink suitable for solvent-free adhesive compounding is:

[0050] 1) Raw materials for primary dispersion: Put all the 15% modified ternary vinyl chloride resin liquid and special additives in the raw materials into the dispersion tank, and slowly add titanium dioxide, fillers, and polyethylene at a stirring speed of 200 rpm For wax, increase the rotation speed to 1500 rpm, and disperse at high speed for 10 to 15 minutes;

[0051] 2) Secondary dispersing and grinding: put 40% of n-propyl acetate and isopropanol into the above-mentioned dispersing tank, disperse for 5 minutes at a stirring speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com