Method for preparing material special for polybutylene terephthalate (PBT) optical fiber loose tubes

A technology of fiber loose and special materials, applied in the direction of fiber mechanical structure, etc., can solve the problems of uneven and unstable product quality, and achieve the effect of reducing and midway transportation, cost saving, considerable economic benefits and social significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

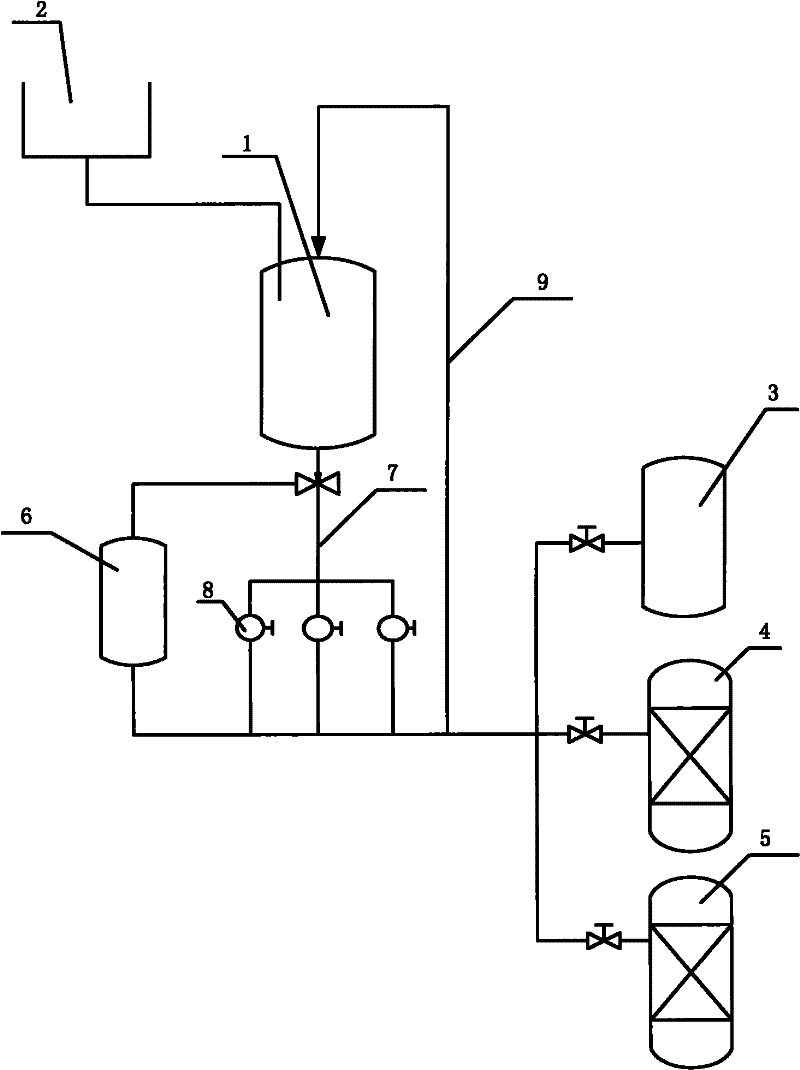

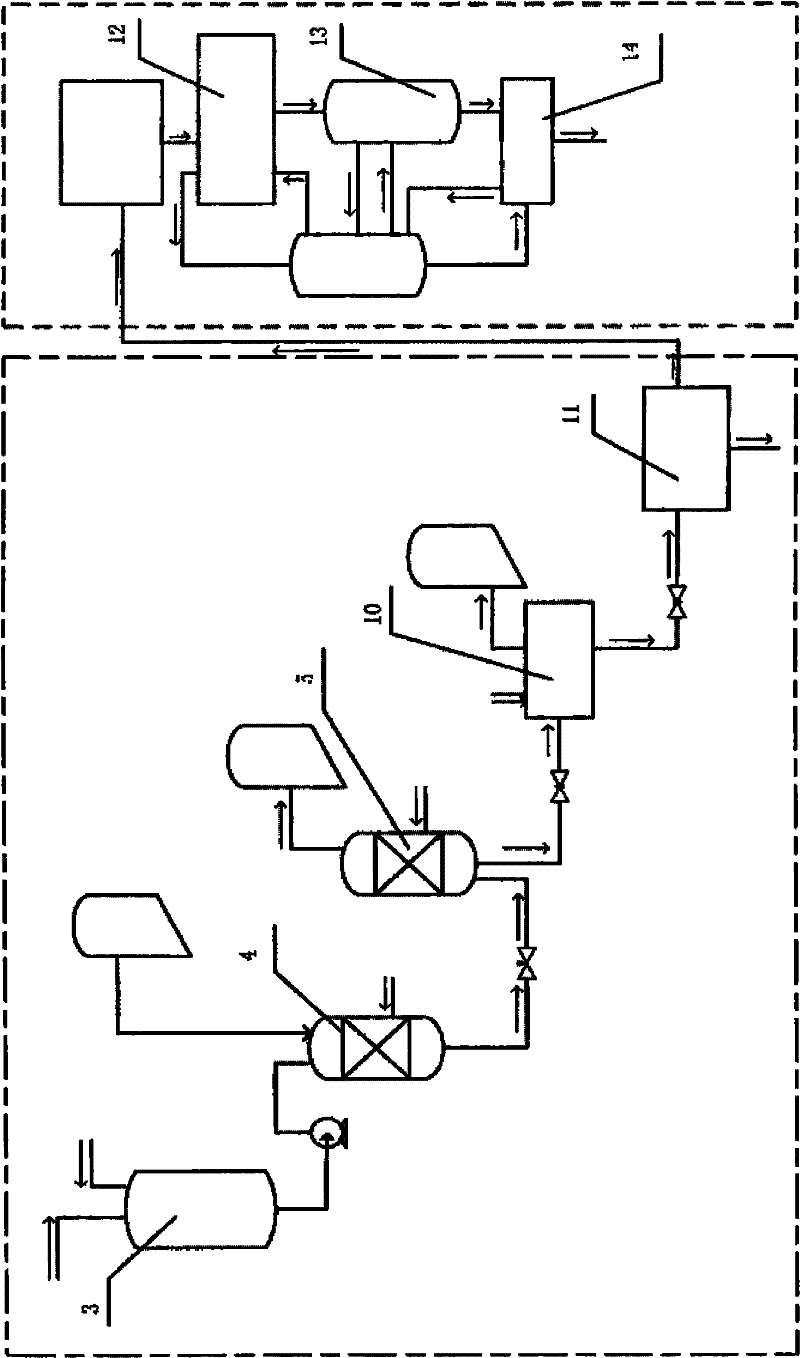

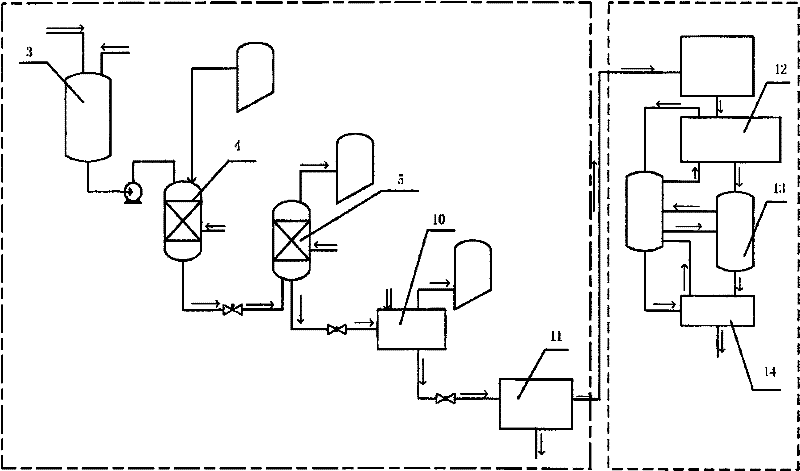

Method used

Image

Examples

Embodiment 1

[0039] The production load of the direct esterification polymerization unit is 30 tons / day, and the production load of the solid phase thickening device is 20 tons / day. 1,4-butanediol and terephthalic acid are prepared into a slurry mixture at a ratio of 1.5:1, and the solid additive and BDO required for the production of PBT optical fiber loose tube are prepared according to the aforementioned method, and then the final product contains about The ratio of 0.5wt% is added to the slurry preparation tank 3 through the gear pump 8, mixed with the slurry, and then entered into the esterification reactor 4. Catalyst tetrabutyl titanate is added into the esterification reactor 4 at a certain concentration. The esterification reaction temperature is about 255°C, and the pressure is controlled at about 200kPa (absolute pressure, the same below). The material in the esterification reactor 4 enters the pre-condensation reactor 5 for polycondensation reaction, the temperature is control...

Embodiment 2

[0042]The production load of the direct esterification polymerization unit is 45 tons / day. The production load of the solid phase thickening device is 20 tons / day. 1,4-butanediol and terephthalic acid are prepared into a slurry mixture at a ratio of 1.5:1, and the solid additive and BDO required for the production of PBT optical fiber loose tube are prepared according to the aforementioned method, and then the final product contains about The proportion is 1wt%, and it is added to the slurry preparation tank 3 through the gear pump 8, mixed with the slurry, and then enters the esterification reactor 4. Catalyst tetrabutyl titanate is added into the esterification reactor 4 at a certain concentration. The esterification reaction temperature is about 260°C, and the pressure is controlled at about 200kPa. The material in the esterification reactor 4 enters the pre-condensation reactor 5 for polycondensation reaction. The temperature of the polycondensation reaction is controlle...

Embodiment 3

[0045] The production load of the direct esterification polymerization unit is 60 tons / day. The production load of the solid phase thickening device is 20 tons / day. 1,4-butanediol and terephthalic acid are prepared into a slurry mixture at a ratio of 1.5:1, and the solid additive and BDO required for the production of PBT optical fiber loose tube are prepared according to the aforementioned method, and then the final product contains about The proportion is 1wt%, and it is added to the slurry preparation tank 3 through the gear pump 8, mixed with the slurry, and then enters the esterification reactor 4. Catalyst tetrabutyl titanate is added into the esterification reactor 4 at a certain concentration. The esterification reaction temperature is about 260°C, and the pressure is controlled at about 200kPa. The material in the esterification reactor 4 enters the pre-condensation reactor 5, the polycondensation reaction temperature is controlled at about 250° C., and the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com