Bi-component slow-reaction polyurea and preparation method thereof

A two-component, polyurea technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of difficult quality assurance and high construction costs, and achieve the effects of slow reaction speed, cost reduction, and good wetting ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1, the embodiment of TDI system:

[0071] When the NCO value is 6.0%, the specific formula is shown in the table below:

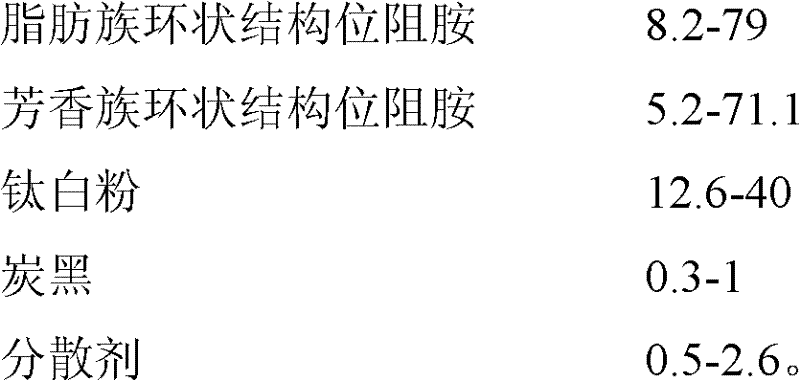

[0072] Component A

[0073]

[0074] Component B

[0075]

[0076] *The ratio of this recipe is A:B=2:1

[0077] Synthesis process of component A: Take TDI, add N-220 at room temperature, raise the temperature to 80°C, react in this temperature range for 3 hours, check the NCO value, and discharge the material after passing the test.

[0078] Synthesis process of component B: Take DesmophenNH1420 and Unilink4200 and add black slurry ground by carbon black, dispersant and additives, then add white slurry ground by titanium dioxide, dispersant and additives, stir and disperse for 30 minutes, and make each The components are evenly dispersed and discharged.

[0079] The polyurea is obtained by mixing the two components A and B.

Embodiment 2

[0080] Embodiment 2MDI system

[0081] When the NCO value is 6.0%, the specific formula is shown in the table below:

[0082] Component A

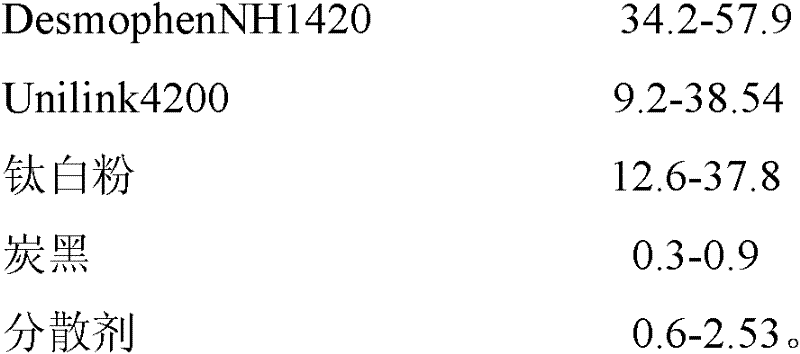

[0083]

[0084] Component B

[0085]

[0086] *The ratio of this recipe is A:B=2:1

[0087] Synthesis process of component A: Take MDI, add N-220 at room temperature, raise the temperature to 80°C, react in this temperature range for 3 hours, check the NCO value, and discharge the material after passing the test.

[0088] Synthesis process of component B: Take DesmophenNH1420 and Unilink4200 and add black slurry ground by carbon black, dispersant and additives, then add white slurry ground by titanium dioxide, dispersant and additives, stir and disperse for 30 minutes, and make each The components are evenly dispersed and discharged.

[0089] The polyurea is obtained by mixing the two components A and B.

Embodiment 3

[0090] Embodiment 3PAPI system

[0091] When the NCO value is 6.0%, the specific formula is shown in the table below:

[0092] Component A

[0093]

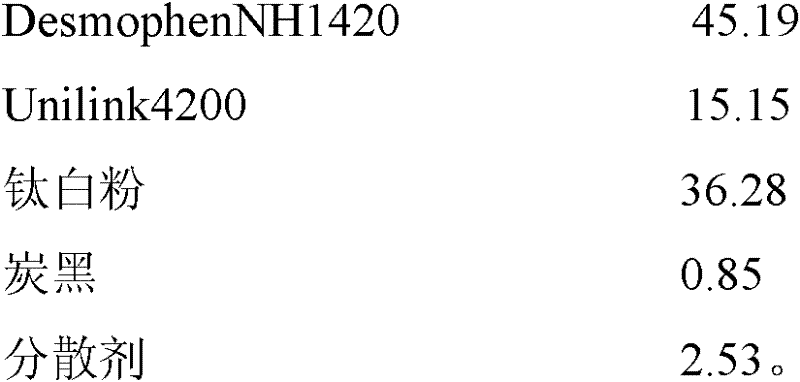

[0094] Component B

[0095]

[0096] *The ratio of this recipe is A:B=2:1

[0097] Synthesis process of component A: Take PAPI, add N-220 at room temperature, raise the temperature to 80°C, react in this temperature range for 3 hours, check the NCO value, and discharge the material after passing the test.

[0098] Synthesis process of component B: Take DesmophenNH1420 and Unilink4200 and add black slurry ground by carbon black, dispersant and additives, then add white slurry ground by titanium dioxide, dispersant and additives, stir and disperse for 30 minutes, and make each The components are evenly dispersed and discharged.

[0099] During construction, mix A and B components to obtain polyurea.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com