Super material harmonic oscillator and preparation method thereof

A harmonic oscillator and metamaterial technology, applied in the field of filters, can solve problems such as difficult to master and high loss, and achieve the effect of thin glass coating, lower sintering temperature, and avoid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

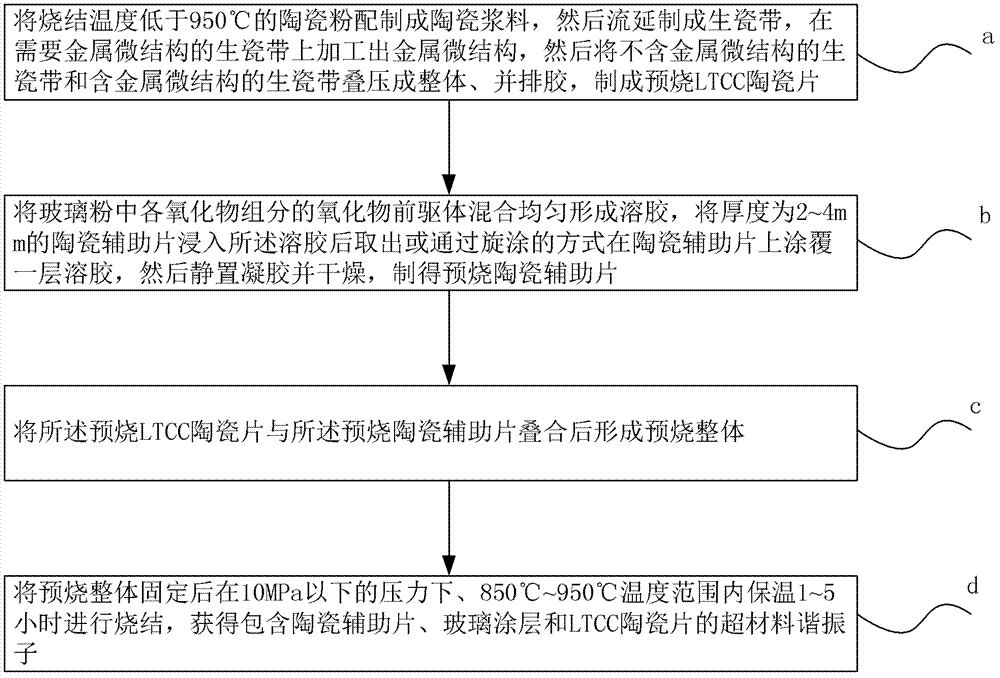

[0020] A preparation method of a metamaterial harmonic oscillator, the preparation method comprising the following steps: as figure 1 shown

[0021] a. Prepare ceramic powder with a sintering temperature lower than 950°C to make a ceramic slurry, and then cast it into a green ceramic belt with a thickness of 20 μm to 200 μm, and process multiple metal microstructures on the green ceramic belt that requires a metal microstructure , and then according to the actual design requirements, the green ceramic tape without metal microstructure and the green ceramic tape with metal microstructure are laminated into a whole and glued side by side to make pre-fired LTCC ceramic sheets;

[0022] b, the glass powder (such as P 2 o 5 -ZnO-Al 2 o 3 -SiO 2 -MgO-CaO system, Bi 2 o 5 -B 2 o 3 -ZnO-Al 2 o 3 -SiO 2 system, etc.), the oxide precursors (corresponding carbonates, hydroxyl salts or metal organic compounds, etc.) of each oxide component in the oxide components are mixed uni...

Embodiment 1

[0029] ZnNb 2 o 6 The ceramic powder of the system is prepared into a ceramic slurry, and 0.5wt% of a sintering aid is added to it, and then cast to form a green ceramic tape with a thickness of 20 μm, and a 350-mesh screen printing is used on the green ceramic tape that requires a metal microstructure A plurality of metal microstructures, the green ceramic strips without metal microstructures and the green ceramic strips containing metal microstructures are placed alternately to form a whole, and glued side by side to make pre-fired LTCC ceramic sheets;

[0030] Will P 2 o 5 -ZnO-Al 2 o 3 -SiO 2 The oxide precursors (corresponding carbonates, hydroxyl salts or metal organic compounds, etc.) of each oxide component in the glass powder of the MgO-CaO system are mixed uniformly to form a sol, and the ceramic auxiliary sheet with a thickness of 2 mm is immersed in the After the above sol is taken out, then the gel is allowed to stand and dried to obtain a pre-fired ceramic ...

Embodiment 2

[0035] Will BaTi 4 o 9 The ceramic powder of the system was prepared into a ceramic slurry, and 1wt% of a sintering aid was added to it, and then flow-cast to form a green ceramic tape with a thickness of 100 μm, and a 370-mesh screen printing was used on the green ceramic tape that required a metal microstructure. A metal microstructure, the green ceramic strips without metal microstructure and the green ceramic strips containing metal microstructure are alternately laminated into a whole, and glued side by side to make pre-fired LTCC ceramic sheets;

[0036] Will P 2 o 5 -ZnO-Al 2 o 3 -SiO 2 The oxide precursors (corresponding carbonates, hydroxyl salts or metal organic compounds, etc.) of each oxide component in the glass powder of the MgO-CaO system are mixed uniformly to form a sol, and the ceramic auxiliary sheet with a thickness of 3 mm is passed through a rotary The method of coating is to apply a layer of sol, then let it stand and dry to make a pre-fired cerami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com